(32936 products available)

Industrial dough presses are mainly classified based on the type and size of the food they are designed to produce, as well as the features and technology used in the machine.

Pizza Dough Press

A pizza dough press machine can help bakery owners flatten pizza dough at scale while ensuring consistency in thickness. It is a popular tool used in pizzerias and bakeries. This machine has two pressing platters top and down. The chef/cook places a dough ball on the bottom platter, and the top platter is lowered on the dough ball to flatten it into a round dough base. More sophisticated pizza dough presses are automated. They use a button press and electric power to flatten dough rounds. Some pizza dough presses have interchangeable platters so that operators can change the shape and size of the dough to be pressed.

Manual Dough Press

A manual dough press requires manual force to press the dough. They are small, compact machines used in home kitchens and small-scale operations. Manual presses operate two platters, which are sometimes known as "boards." The dough piece is placed on the bottom board where the top board is lowered over the dough piece. The top board is pushed down with manual force to press the dough into the desired shape and size. Because they are small and require manual force to operate, manual presses are often used for non-commercial applications where the demand for pressed dough is low.

Pie Dough Press

Besides pressing pizza dough, bakery owners may need to press pie dough. A pie dough press works similarly to a pizza dough press, but it has a distinct pressing platter shape. The pressing tool has a round or scalloped-shaped platter that resembles the shape of a pie. Like the pizza press, there are manual and automatic pie dough presses that bakery owners can use to achieve consistency in dough size and shape.

Rotary Dough Press

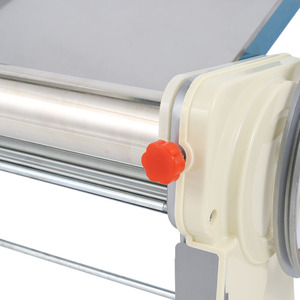

A rotary dough press is an automated machine that flattens dough using pressing plates and digital technology. The dough pieces are fed into the machine, and a motor pulls them through the pressing area where they are flattened into the desired sizes and shapes. Operators can use a rotary dough press to make flatbread, tortillas, and pizza dough. Surface area and production capacity are some things operators should look for when buying a rotary dough press.

Generally, the specifications of a dough pressing machine vary depending on the model and what it has been manufactured to do. Other factors are the capability, dimensions, weight, and pressing capacity of the machine.

First, the pressing capacity of a dough press will vary. Some machines, like the pizza dough press, have a capacity that varies from 85 to 90 kg or 187 to 198 lbs per 24 hours. The small-scale machines (manual presses) stay between 50 to 60 kg or 110 to 132 lbs. The production capacity increases in the ratio depending on the automation of the machine-the more automated, the higher the capacity. Large-scale industrial presses have more sophisticated technology enabling 600 to 700 kg or 1320 to 1540 lbs a day. Larger presses are also more costly, and the price difference is usually vast.

Second, dimensions, weight, and pressing areas vary according to what is being pressed. A pizza dough press machine would generally measure about 30 x 30 x 36 in, while a tortilla machine could measure 80 x 50 x 54. Another factor that affects the dimensions is whether it is countertop or floor standing. Floor-standing machines are bigger and longer than countertop machines, which are more handy and easy to use in a kitchen setting.

The weight of the machine will also differ depending on whether it is a manual machine or a more automated machine. For example, a tortilla press machine may weigh around 370 lbs, while a pizza press machine weighs around 200 lbs.

Finally, the pressing area varies depending on what is being pressed. For example, a pizza pressing machine will have a pressing area of 12 inches to 36 inches, while an Alfajores dough press will have 24 cutter plates to cut out small cookies. Other cut-out shapes are star shapes or heart shapes. When looking at pressing areas, the biggest pressing area is in industrial-scale machines because they need to cater to larger-scale production needs. The dimensions will also differ as they need to be set up in a larger area.

Dough presses require some routine maintenance to ensure they work smoothly and optimally. Some general tips are as follows:

Dough presses are used in various industries to produce food at scale. Here are some common applications for dough presses.

Food Service Industry

Dough presses are widely used in the food service sector to create large volumes of food items efficiently. Restaurants, cafes, and catering services often require dough presses to produce pizza bases, pastries, pies, and other dough products in significant quantities to meet customer demands.

Pizza Production

Dough presses are essential tools in pizza production facilities, whether small-scale pizzerias or large commercial pizza factories. These presses allow for the rapid production of pizza crusts, ensuring consistency in size and thickness. Automated dough presses with high production speeds are commonly used in pizza production to meet the high-demanding for pizzas.

Bakery Production

Dough presses play a vital role in bakery production, both in industrial-scale bakeries and artisanal bakeries. These presses are used to shape bread, croissants, danishes, puff pastry, and other baked goods. Bakery operations can increase efficiency and streamline production processes by pressing dough to the desired shapes and sizes.

Frozen Food Manufacturing

Dough presses are used in frozen food manufacturing to produce pre-made dough products that will be frozen and sold to consumers or food service establishments. These presses ensure consistency in dough shapes and sizes, making it easier to portion and freeze the pressed dough for later use.

Snack Food Production

Dough presses are employed in snack food production facilities to create various dough-based snacks such as cookies, crackers, biscuits, and puff pastry snacks. The presses shape the dough into specific forms, which are then baked or fried to produce the final snack products.

When buying dough presses, buyers should consider the construction material used to make the dough press. The construction material affects the durability, strength, and maintenance needs of the machine. In recent years, stainless steel has emerged as the industry standard construction material for food processing machines, including dough presses.

Food safety is a major consideration for many applications. Stainless steel dough presses offer the intrinsic advantage of superior hygienic properties. They resist microbial growth, meaning bacteria are less likely to thrive on their surfaces. This characteristic improves food safety by lowering contamination risks, thereby protecting consumers' health.

The durability of stainless steel is a critical reason businesses often opt for it. With proper maintenance, stainless steel dough presses can last for a decade or more. Their toughness ensures they withstand frequent use in commercial settings compared to other materials that might wear out quickly. Investing in stainless steel dough presses provides long-term value for business owners who need reliable equipment that will serve them well over time with minimal repairs or replacements required.

Aside from durability, presses made from stainless steel are easier to sterilize than their wooden and plastic counterparts. This simplifies the maintenance process for food handlers who must ensure their equipment is always clean and safe to use. Wooden dough presses can absorb moisture, leading to mold and other microbial growth. Therefore, businesses looking for easy-to-maintain machinery should consider dough presses that are made of stainless steel.

Depending on the business needs, buyers should also consider the production capacity of the dough press. The size and dimensions of the dough press are also important. Before placing bulk orders, buyers should consider sample testing to ensure the dimensions meet business needs and customers' expectations.

Presses with adjustable thickness settings are a preferred option since they offer versatility. Thickness adjustability allows food businesses to create products with varying crust thickness. This feature eliminates the need to purchase additional equipment to achieve distinct product characteristics, thereby streamlining production processes and reducing operational costs.

Q1. What types of dough presses are there?

A1. There are two main types of dough presses. Firstly, the manual dough press is dependent on the force provided by the operator pressing down on the handle to create the press. Secondly, the automatic dough press uses electricity to operate. It often has multiple programs and can mass produce items.

Q2. How thick does a dough press make?

A2. The average thickness of dough presses is about 3-15mm, but this may differ depending on the machine and the product being pressed.

Q3. What material is a dough press made from?

A3. The main material used for dough presses is stainless steel, but some older models may use cast iron. The pressing discs could be made of aluminum or cast iron, as those materials can withstand heavy pressure.

A4. Q4. Can a dough press's thickness be adjusted?

A4. Yes, the thickness can be adjusted according to what is required. Usually, the standard thickness is 10mm, but it can go as low as 5-8mm when pressing pizza dough and up to 15-20mm when pressing burger dough.