(5468 products available)

Diamond silicon carbide is a product that has several applications. Users should understand that this product can come in different types. It all depends on its intended use. These materials range from abrasives and cutting tools to advanced electronics.

Here are the common types of diamond silicon carbide that buyers can get:

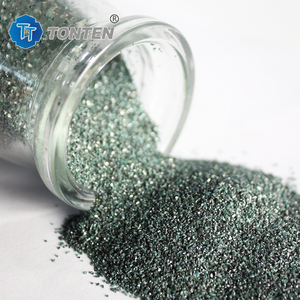

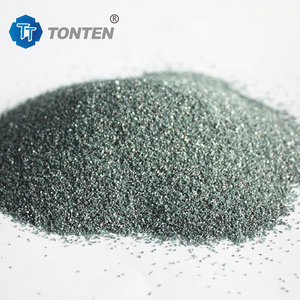

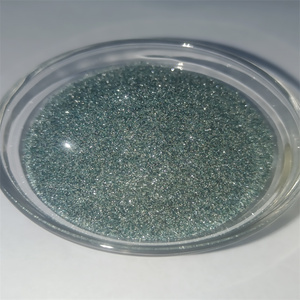

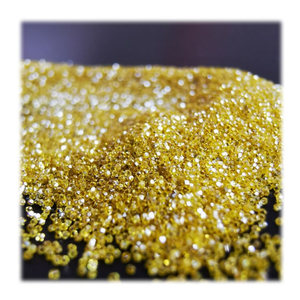

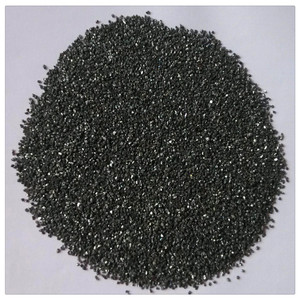

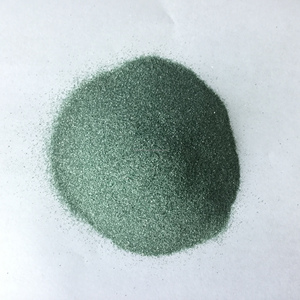

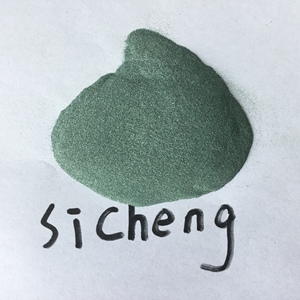

Abrasive Grains

Silicon carbide grains embedded with diamond particles create extremely hard and long-lasting abrasive materials. Silicon carbide is the most used abrasive in cutting hard materials. Diamond grains in the mix improve the cutting performance and lifespan of the abrasives.

Grinding Wheels

Diamond silicon carbide grinding wheels are ideal for precision grinding of hard materials. These include ceramics, glass, and hardened steels. These grinding wheels provide a sharp cutting edge that maintains its effectiveness over extended use.

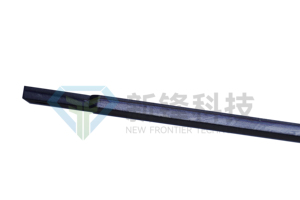

Cutting Tools

In machining and material processing industries, tools must withstand the rigors of the job while maintaining precision. Cutting tools such as saw blades and router bits integrate diamond and silicon carbide for durability and fine cutting.

Stone Polishing

The construction industry finds polished stones and tiles more attractive and suitable for use. To achieve this finish, polishing pads that contain diamond silicon carbide are used to give stones a sleek shine.

Electronics

Silicon carbide is an important semiconductor with applications in high-power and high-frequency devices. Adding diamonds to silicon carbide can improve the thermal conductivity of electronic devices.

Rings and Discs of Silicon Carbide

Silicon carbide rings and discs are popular. The reason is that they offer excellent resistance to wear and corrosion. These components are essential in various industrial applications, including pumps, grinding mills, and slurries, where longevity and reliability are key.

The combination of diamond and silicon carbide results in a composite material that has several benefits. This means it can adapt to various requirements, thus making it a practical choice in multiple applications.

As mentioned before, silicon carbide is a very hard and thermally stable material. It can withstand such conditions as high temperatures, chemical exposure, and wear. Silicon carbide alone can handle all these stressors. But when diamond is added to the mix, it enhances the grindability, cutting edge, and precision.

This silicon carbide diamond combination can then manufacture various products. These products include diamond silicon carbide grinding wheels, discs, cutting tools, and abrasives.

This product's durability, hardness, thermal conductivity, versatility, and fine edge are what makes it stand out from other products. Note that silicon carbide is more brittle than other hard materials. But combining it with diamond forms a strong composite that can easily cut or grind very tough materials.

The design aspects of diamond silicon carbide revolve around its practical applications and how to enhance its effectiveness. The nature of the diamond particles and the silicon carbide grains determines the quality and performance of the composite.

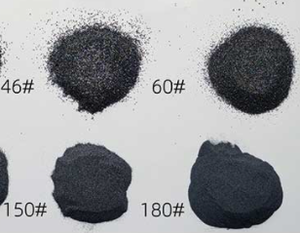

This means the diamond particles' size, shape, and distribution will all affect grinding or cutting performance. Smaller particles provide a finer finish, while larger ones enhance material removal rates.

Silicon carbide grain size can vary to suit different applications. Fine grains provide a smooth finish, while coarse grains improve cutting speed. The bonding material used to hold the diamond particles in place must be strong enough to withstand the forces. At the same time, it should allow for new sharp edges to emerge as the worn ones become blunt.

For diamond silicon carbide grinding wheels, the wheel composition, shape, and bonding all impact the grinding process. Wheels designed with varying concentrations of diamond can cater to light or heavy-duty grinding.

In diamond silicon carbide rings, the rings' hardness and wear resistance make them suitable for applications like cutting and grinding machines. These rings sometimes serve as sealing components in pumps, where they resist wear from abrasive liquids or solids.

Knowing the different scenarios can ensure users effectively utilize diamond silicon carbide products in their businesses. These products are what users employ in cutting, grinding, polishing, and manufacturing.

Stone Cutting and Polishing

The construction industry has merchants cutting and polishing granite, marble, and other stones. These merchants use diamond polishing discs that contain silicon carbide. This disc ideal for giving the stones a smooth and shiny finish.

Aerospace and Automotive Engineering

Aerospace and automotive industries utilize silicon carbide tools in their projects. That is because they offer precision machining for hard materials. In these ventures, silicon carbide diamond abrasives help grind engine components, brake discs, and aerospace parts.

Electronic Manufacturing

The electronics industry has high demand for materials that can be usable in high temperature and power. As such, silicon carbide is a go-to semiconductor. Thus, silicon carbide diamond grinding allows precise shaping of silicon carbide wafers. This makes them suitable for high-power electronic devices.

Railway and Heavy Equipment

Railway and heavy equipment ventures seek grinding wheels that can handle the tough tasks of their jobs. So, for these industries, diamond grinding wheels that have silicon carbide are ideal for grinding brake discs, wheels, and other critical components. The wheels provide a balance of durability and performance.

Innovative Composites

Many businesses experiment with diamond silicon carbide. They seek to develop new composite materials for emerging technologies. Users can customize the ratio of diamond and silicon carbide to suit specific needs.

Industrial Machining

Many industrial machining workshops use silicon carbide diamond tools to cut hard metals like tungsten carbide and hardened steel. The tools maintain sharper longer, improving efficiency in mass production.

So, how does one choose the silicon carbide diamond product that suits their business's needs? There are several considerations to evaluate for a silicon carbide product to adequately meet the client's needs.

Wire electro-discharge machining

This method uses a thin wire as an electrode to cut materials and form desired shapes such as wheels and rings. It is often used for complex shapes and designs.

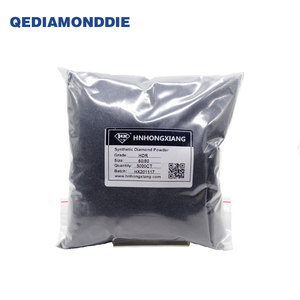

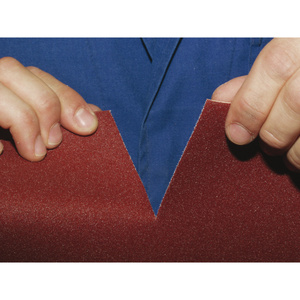

Grinding/cutting

Using grinding or cutting methods, suppliers can make silicon carbide into powders of various sizes. Manufacturing businesses should pay attention to the powder size. This is because smaller sizes create a smoother finish, while larger ones enhance material removal.

Hot pressing and sintering

This process forms silicon carbide into wheels and discs. In this process, silicon carbide powder is heated under high pressure to create a solid piece. It is often used to make parts with a high density suitable for heavy-duty tasks.

Machining

For silicon carbide parts like grinding wheels, disc, and ring machining can refine the shape and finish. They can turn or mill silicon carbide to achieve the desired profile and smooth finish. Merchants should get an even silicon carbide disc or wheels suitable for their customers' needs. An uneven disc or wheel will affect the quality of the end product.

Chemical vapor deposition (CVD)

This process deposits a thin layer of silicon carbide onto a substrate using vapors. This technique is used to create custom parts with specific thicknesses and properties. Businesses may also get silicon carbide grinding wheels through this process. It allows for finer control over the material's microstructure.

A1. Yes, they can. Several manufacturers can customize silicon carbide diamond tools to meet particular business needs. They usually will adjust the size, shape, and concentration of diamond particles. These adjustments ensure the tools perform optimally for their clients' specific applications.

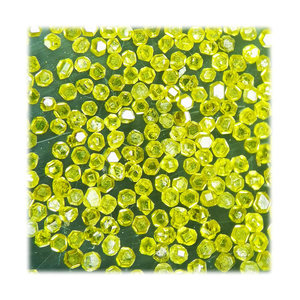

A2. Silicon carbide itself has a Mohs hardness of 9. This makes it one of the hardest materials. When combined with diamond, which has a hardness of 10, it creates an inseparable and highly durable composite. This allows the product to easily cut or grind the toughest materials compared to other available hard materials.

A3. The key benefit is enhanced precision. The wheels are ideal in machining hard metals like tungsten carbide and hardened steel. The wheels maintain their sharpness under rigorous use. This improves efficiency, reducing downtime. Moreover, they bring exceptional thermal conductivity, which helps prevent overheating during large manufacturing runs.

A4. The first step in prolonging the tools' life is properly storing them in a cool, dry place free from moisture and contaminants. They should also protect silicon carbide wheels or discs from impact or rough handling to avoid damage. Then use the tools correctly. This means using them at the recommended speed and pressure. Lastly, cleaning the tools after use will remove debris.

A5. Businesses must consider the silicon carbide grain size and silicon carbide grit size to ensure they meet their clients' precise needs. Moreover, they must analyze the bond type. Different bonds are suitable for different tasks. So, carefully evaluate the bond type. Lastly, they should get silicon carbide tools from a reputable brand for quality assurance.