(119 products available)

Diamond pattern grates are decorative metal or fiberglass mesh sheets with a diamond-shaped pattern. This design allows for airflow and light while providing a sturdy surface. These trays have applications in construction, home improvement, and industrial settings. Below are some of the common types of diamond pattern grates:

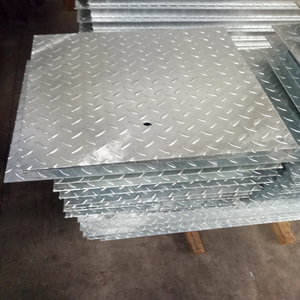

Steel diamond pattern grate

Steel tread plates are also known as diamond plates or checkered plates. These non-slip steel sheets have raised diamonds on one side and a flat surface on the other. Their design imparts strength and rigidity. The raised diamonds increase friction and prevent slipping. Steel tread plates are used as load-bearing walkways or stair treads in industrial settings. They can also be used for aesthetic applications in cars, trucks, and motorcycles. Steel grates have high carbon content, making them very durable. They can withstand heavy impact and intermittent high heat.

Aluminum grates

Aluminum grates are lightweight and corrosion-resistant. They are often used in outdoor applications or areas exposed to moisture. These aluminum trays are suitable for pedestrian walkways, drainage covers, and ventilation areas. They are easy to handle and install. Aluminum grates have a high strength-to-weight ratio. They provide adequate support for foot traffic while being lightweight.

Fiberglass diamond pattern grates

These grates are lightweight, non-conductive, and corrosion-resistant. They are commonly used in industrial environments where electrical conductivity and corrosion are concerns. Fiberglass grates offer high strength and durability.

Brass and stainless steel pattern trays

Brass and stainless steel grates offer a more elegant and decorative look. They are often used in interior design applications, such as in homes, offices, and retail spaces. These metal pattern trays are resistant to rust. They also have a shiny surface that is visually appealing. They can easily blend into luxury interior settings.

Perforated diamond pattern grates

Perforated pattern grates have holes in a diamond pattern. They allow for ventilation and drainage. These perforated grates are used in applications where water runoff is necessary, like drainage systems and industrial areas.

Expanded metal pattern trays

These are made from a single sheet of metal that is cut and stretched to form a diamond pattern. They are very rigid and allow maximum airflow. Expanded metal grates are commonly used in industrial applications and factory settings.

As earlier mentioned, the diamond pattern grate is primarily used for drainage covers. It has multiple features that make it an excellent choice for areas with high water runoff. Some of the grate's features include:

There are various applications for metal diamond mesh in construction, infrastructure and home projects. This includes:

When choosing a drain cover, it is important to consider different factors to ensure the right choice is made. Some factors to consider include the material, the size, where the grate will be installed, and the load it will carry.

The diamond pattern grille is popular for its aesthetic look and functionality. It is important to consider the style of the area where it will be installed to ensure it matches. A stainless steel drain cover with a diamond pattern is a beautiful addition to any space.

The size of the grate should be considered to ensure it fits the area where it will be installed. The size of the pipe connected to the drain also needs to be taken into consideration. These grates come in different sizes and can also be customized to fit a specific area.

Another important thing to consider is the pattern on the grate. The look of the grate will be affected by the style of the pattern. The water flow will also be affected by the style of the pattern, so it is important to consider the amount of water that needs to be drained.

The load bearing capacity of the grate should also be considered. Different types of diamond pattern grates can support different loads. The area where the grate will be installed should be looked at to determine the amount of weight it can support. The thickness of the grate will affect how much weight it can support.

the finish of the grate will affect how well it can withstand rust and corrosion. A polished finish is easy to clean but more susceptible to rust and corrosion. A brush finish offers more protection from rust and corrosion but is harder to clean. A mirror finish offers the best protection from rust and corrosion and is easy to clean.

Q1: How are floor diamond pattern grates maintained?

A1: Cast iron can be cleaned with water and soap. Stainless steel can be cleaned with water and vinegar to prevent rust. Check with the manufacturer for specific maintenance instructions.

Q2: What kinds of diamonds can be found on heating grates?

A2: There are two types of diamonds on heating grates: The single diamond shape, which is one big diamond in the middle of the grate, and the double diamond pattern, which has two diamonds that are vertical and parallel in the middle of the grate.

Q3: What are the disadvantages of cast iron floor diamond pattern grates?

A3: Cast iron grates rust easily, so they need to be maintained well. They are also heavy and can crack if dropped or hit for any reason. Additionally, they can warp from extreme heat.

Q4: What are the disadvantages of stainless steel floor diamond pattern grates?

A4: Stainless steel can become very hot when used on furnaces. It can also get scratched and show dirt and fingerprints more easily than other materials. High-quality stainless steel is needed to prevent rust.

Q5: What are the disadvantages of aluminum furnace diamond pattern grates?

A5: Although aluminum won't rust, it can be soft and easily dented or scratched. It also doesn't hold heat as well as cast iron or steel. Additionally, aluminum can become very affordable when placed over a hot surface.