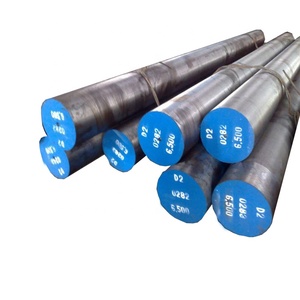

Introduction to D2 Steel

D2 steel is an exceptional tool steel known for its high wear resistance and versatility, making it one of the most sought-after materials in the manufacturing and tooling industries. It is an air-hardening, high-carbon, high-chromium alloy that strikes an ideal balance between excellent hardness and toughness. Commonly employed in various applications, D2 steel is favored for its longevity and performance under stress.

Types of D2 Steel

D2 steel can be categorized based on its treatment processes and forms. Understanding the different types can help businesses select the ideal product for their specific needs.

- Annealed D2 Steel: This form is delivered in a softer state, allowing for easier machining and fabrication.

- Hardened D2 Steel: After heat treatment, this form gains impressive hardness, making it suitable for creating cutting tools and dies.

- Pre-hardened D2 Steel: Slightly less hard than fully hardened steel, this version allows for further machining without excessive wear.

- Cold-work D2 Steel: Tailored for applications requiring precise shapes and less deformation under cold working processes.

Functions and Features of D2 Steel

D2 steel is recognized for its myriad of functions and distinctive features, allowing it to perform exceptionally in various demanding environments.

- High Wear Resistance: The high chromium content provides remarkable abrasion resistance, making it perfect for tools that undergo frequent friction.

- Edge Retention: D2 steel’s toughness allows it to retain a sharp edge for extended periods, reducing the need for frequent sharpening.

- Versatile Applications: From automotive tools to industrial knives, D2 steel is used in diverse fields, proving its adaptability.

- Excellent Dimensional Stability: It maintains its shape well even under extreme operating conditions, ensuring precision in manufacturing.

Applications of D2 Steel

The robust characteristics of D2 steel lend it to a vast array of industrial applications, providing reliable performance in various conditions.

- Cutting Tools: Ideal for manufacturing of tool bits, blades, and shears due to its sharp edge retention and hardness.

- Molds and Dies: Utilized extensively in the production of injection molds and die casting, where durability is crucial.

- Automotive Components: Frequently found in the automotive industry for parts that require enhanced wear resistance.

- Metal Fabrication: Commonly used in the production of fixtures and fixtures that require high durability under constant use.

Advantages of D2 Steel

Choosing D2 steel for your applications comes with several advantages that enhance operational efficiency and product lifespan.

- Longevity: The wear-resistant properties provide a longer service life, making it a cost-effective material in the long term.

- Strong Hardness: Ability to withstand heavy loads without deforming, ensuring reliability under challenging conditions.

- Enhanced Performance: Due to its unique formulation, D2 steel maintains a high level of performance under stress, reducing downtime.

- Ease of Maintenance: While requiring less frequent sharpening, D2 steel tools can be more easily honed compared to softer steels, providing further convenience.

In conclusion, D2 steel stands out in the competitive landscape of materials for industrial tools and components. Its distinctive features, various types, and broad application range make it an exemplary choice for businesses aiming to increase efficiency and reliability in their operations.