(2415 products available)

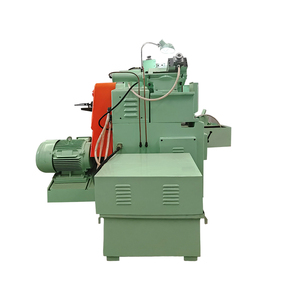

A CNC cylindrical grinder is a precision machine tool that utilizes computer numerical control to automate the grinding process of cylindrical workpieces. This type of grinder is widely used in various industries such as automotive, aerospace, and manufacturing to achieve high precision and efficiency in grinding operations.

When looking at a CNC cylindrical grinder, it's essential to consider key technical specifications. These machines typically offer a range of features, including cnc cylindrical grinding machine, cnc cylindrical grinder, studer grinder, kellenberger grinders, and cnc od grinder. Some common technical specifications include the grinding diameter, distance between centers, grinding wheel size, and spindle speed.

CNC cylindrical grinders offer several advantages. Firstly, they provide precise and consistent results, ensuring uniformity in the finished workpiece. Secondly, the automated nature of CNC grinders reduces manual intervention, leading to increased productivity and efficiency. Additionally, these machines are versatile and can handle a wide range of workpiece sizes and materials, making them suitable for various applications.

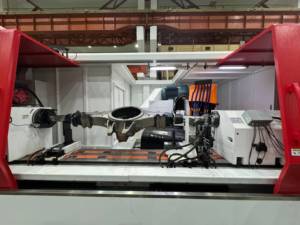

Modern CNC cylindrical grinders come equipped with advanced features to enhance performance and accuracy. These features may include multi-axis control for complex grinding operations, in-process gauging systems for real-time measurement feedback, automatic tool changers for increased efficiency, and user-friendly CNC programming interfaces for ease of operation.

When selecting a CNC cylindrical grinder for your business, it's crucial to assess your specific requirements carefully. Consider factors such as the type of workpieces you'll be grinding, the level of precision needed, production volume, and available floor space. Additionally, evaluate the machine's technical specifications and features to ensure they align with your operational needs.

CNC cylindrical grinders find applications in various industries and scenarios. For instance, in the automotive industry, these machines are used for grinding engine components, shafts, and transmission parts with high precision. In the aerospace sector, CNC cylindrical grinders play a vital role in producing components for aircraft engines, landing gear, and other critical systems.

Proper maintenance is essential to ensure the longevity and performance of CNC cylindrical grinders. Regularly inspecting key components such as the grinding wheel, spindle, and hydraulic system can help prevent unexpected downtime and maintain consistent quality in grinding operations. Additionally, following manufacturer-recommended maintenance schedules and procedures is crucial to keep the machine in optimal working condition.

In conclusion, CNC cylindrical grinders are sophisticated machines that offer precision, efficiency, and versatility in grinding operations. Understanding the technical specifications, advantages, features, and maintenance requirements of these machines is crucial for businesses looking to invest in CNC grinding technology. By choosing the right CNC cylindrical grinder and implementing proper maintenance practices, businesses can enhance their manufacturing processes and achieve high-quality results.