Understanding Custom Reducers

Custom reducers play a crucial role in various industries, providing tailored solutions for flow control and fluid dynamics. These devices are designed to reduce the flow or pressure of liquids and gases, ensuring that processes run smoothly and efficiently. With their unique capabilities, custom reducers offer an exceptionally versatile approach to managing system specifications and optimizing performance.

Types of Custom Reducers

- Concentric Reducers: These reducers feature a continuous funnel shape, allowing for smooth transitions in flow. Ideal for pipelines where space is limited, concentric reducers are perfect for systems that require high flow rates.

- Excentric Reducers: Characterized by an off-centered design, these reducers are effective for shifting fluid paths. Excentric reducers minimize pressure loss and are suitable for applications where turbulence needs to be controlled.

- Fabricated Reducers: Constructed from various materials, fabricated reducers can be customized to fit specific dimensions and performance requirements. They are ideal for bespoke installations in industrial settings.

- Victaulic Reducers: These are grooved pipe fittings that allow for easy connections. Ideal for quick assembly and disassembly, Victaulic reducers are commonly used in fire protection and HVAC systems.

Features and Functions of Custom Reducers

- Flow Regulation: Custom reducers are essential for modulating flow rates in pipelines, ensuring systems operate within desired parameters.

- Pressure Management: They effectively manage pressure variations, protecting downstream equipment and enhancing overall system reliability.

- Material Versatility: Available in various materials such as stainless steel, PVC, and copper, these reducers can be customized according to the application environment, from corrosive fluids to high-temperature steam.

- Custom Sizes and Configurations: Tailored dimensions and shapes enable seamless integration into existing systems, offering a bespoke solution to unique installation challenges.

Applications of Custom Reducers

- Manufacturing: In industrial settings, custom reducers help manage the flow of liquids and gases critical to production processes, enhancing efficiency and lowering operational costs.

- HVAC Systems: Custom reducers are essential for balancing airflow within heating, ventilation, and air conditioning systems, ensuring optimal performance and comfort.

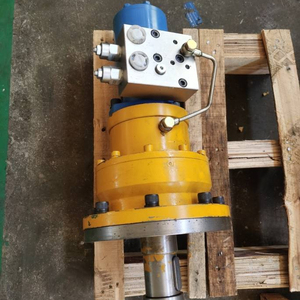

- Pneumatic & Hydraulic Systems: These devices are vital for ensuring reliable pressure levels in pneumatic tools and hydraulic machinery, sustaining consistent operation levels.

- Water Supply Systems: Custom reducers help in managing water distribution, preventing pressure surges, and improving the efficiency of plumbing systems.

Advantages of Utilizing Custom Reducers

- Enhanced Performance: By precisely controlling fluid flow and pressure, custom reducers contribute to smoother operations, reducing wear and tear on equipment.

- Cost-Effectiveness: Tailored solutions can minimize material waste during production and installation, ultimately leading to lower operational expenses.

- Increased System Durability: The right materials and designs help custom reducers withstand varying environmental conditions, contributing to longer-lasting infrastructure.

- Improved Safety: By mitigating risks associated with pressure build-up and ensuring balanced flow, custom reducers enhance the safety of various applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4