(5688 products available)

Custom plain steel grating is applicable in diverse industries. It is manufactured in different styles to meet the requirements of various industries. The types of steel grating include:

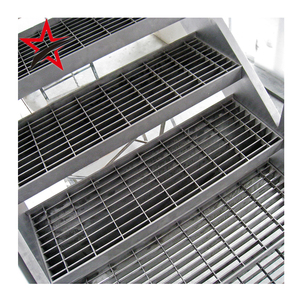

Bar Grating

This form of custom plain steel grating comes in carbon, galvanized, and stainless steel. It is constructed with load bars and cross bars. The load bars run parallel to the direction of the support. At the same time, the cross bars run perpendicular to the load bars. This steel grating offers a high level of strength. It also provides excellent ventilation and light. The bar grating is used in applications such as walkways, platforms, and industrial flooring.

Diamond Plate Grating

This grating is also known as a checker plate or tread plate. It features a raised diamond pattern on its surface. The design increases traction and reduces slipping. This type of grating is durable and corrosion-resistant. It is primarily used in high-traffic areas and applications where safety is essential.

Fiberglass Reinforced Grating (FRP)

This grating is also known as a checker plate or tread plate. It features a raised diamond pattern on its surface. The design increases traction and reduces slipping. This type of grating is durable and corrosion-resistant. It is primarily used in high-traffic areas and applications where safety is essential.

Swage-Locked Grating

This type of grating is constructed using a swaging machine. It locks the load bars and cross bars with a mechanical swaged joint. This joint increases strength and stability. Swage-locked grating is used in applications where heavy loads are experienced. It includes power plants, water treatment facilities, and industrial plants.

Perforated Metal Grating

This custom plain steel grating is constructed from metal sheets. The sheets are pierced with patterns of holes. The holes can be round, square, or triangle-shaped. Perforated metal grating offers lightweight construction. It also provides high slip resistance and ventilation. It's used in applications such as stair treads, platforms, and walkways.

Press-Locked Grating

This type of grating is constructed with high-pressure locks. It creates a firm and stable connection between load bars and cross bars. The pressure-locked grating is ideal for applications that require high strength and rigidity. It is also resistant to wind and seismic activities.

Strong Load-Bearing Capacity:

Custom plain steel grating offers exceptional load-bearing capacity. Its robust construction allows it to withstand heavy foot traffic and equipment. This makes it ideal for applications in environments requiring high durability and strength. Moreover, the high-strength steel bars used in the manufacture of this product ensure long-term performance with minimal deflection or deformation under load.

Enhanced Slip Resistance:

Safety is paramount in industrial and commercial settings. Custom plain steel grating features a variety of slip-resistant surface options. These include: serrated/chevron patterns which provide traction in high-traffic areas. The slip-resistant characteristics reduce the risk of accidents and offer a secure footing even when exposed to moisture or spills.

Optimal Light and Airflow:

Plain steel grating allows the free flow of natural light and ventilation. This feature is important in environments where light and air are necessary. For instance, it includes: greenhouse structures and open-air parking lots. Moreover, the airflow reduces the accumulation of debris and facilitates drainage, making it easier to maintain the cleanliness of the grating.

Durability and Longevity:

Another key feature of custom plain steel grating is durability. It is designed to endure the harshest environments. It includes: extreme temperatures, corrosive substances and heavy impact. This guarantees a long service life with little maintenance. Additionally, it is available in various finishes including galvanized, painted or powder-coated. These finishes offer varying degrees of corrosion resistance to accommodate specific environmental conditions and customer preferences.

Easy Installation and Low Maintenance:

Convenient installation is a key consideration when designing custom plain steel grating. It is designed for quick assembly and disassembly. This eases the installation process and reduces the downtime of projects. Furthermore, it requires minimal maintenance. Regular cleaning is enough to preserve its structural integrity and appearance. This feature lowers the long-term maintenance cost and increases its cost-effectiveness in the long run.

Customizable Designs and Dimensions:

Every project has unique requirements and challenges. Thus, custom plain steel grating offers a solution to this challenge by providing customizable designs and dimensions. This product comes in different bar spacing, thicknesses and surface finishes. This allows it to meet the specific aesthetic and functional requirements of diverse applications. Moreover, the customization capability maximizes performance and enhances the visual appeal of the grating. This makes it integrate seamlessly into any architectural design.

Custom steel grating offers practical solutions in various industries and applications, providing durability, safety, and functionality. Here are some usage scenarios:

Choosing the right steel grating for a project involves considering various factors. Here is a list of some of them:

Load-bearing capacity

Each steel grating has different load capacities depending on the type and design. It's essential to choose a steel grating that can withstand the expected loads and environmental conditions. Consider factors like the span distance between supports, the load type (point load or distributed load), and the load frequency (static or dynamic).

Slip resistance

The safety of the steel grating is vital in areas where it will be exposed to water or other liquids. It's crucial to choose a steel grating with a high slip resistance to reduce the risk of accidents. Consider factors like the surface texture, the drainage capability, and the footwear type.

Corrosion resistance

Another key factor to consider is the environmental conditions. This is because harsh conditions can damage plain steel grating. It's advisable to choose a grating that can withstand the environmental conditions. For example, hot-dip galvanized or coated steel plat grating is suitable for coastal areas with high humidity and saline water. Alternatively, stainless steel or fiberglass reinforced plastic (FRP) grating is suitable for acidic or chemical environments.

Ease of installation and maintenance

It's important to consider the installation process and the long-term maintenance requirements. Go for a steel grating that is easy to install and requires little or no maintenance. This will help save time and money. Therefore, consider factors like the weight, the connection type, and the maintenance frequency.

Aesthetics

The aesthetics of the steel grating is vital in applications where it is visible. It's important to choose a steel grating that complements the project's design and style. Consider factors like the color, the texture, and the pattern.

Q1: Is it possible to powder coat or paint over my custom steel grating to prevent rusting?

A1: Yes, you can epoxy paint or powder coat the plain custom steel grating to prevent rusting. The coating process also improves the aesthetics of the steel grating. However, the coating will not be permanent, and it will need to be reapplied from time to time.

Q2: What is the difference between a steel grid and a floor grid?

A2: The difference between a load-bearing and floor grid can be distinguished based on the application. A solid steel grid can be used as a support base for heavy machinery or equipment in factories, walkways, and platforms. On the other hand, floor grids are ideal for use in flooring.

Q3: How is the load capacity of custom plain steel grid bars determined?

A3: The load capacity of the steel grid bar is determined by the bar thickness, the spacing between the bars, and the steel quality. It can also be calculated using engineering load charts.

Q4: What are the industries that use custom steel grids?

A4: The industries that use steel grids include the construction, oil and gas, agriculture, electricity and power generation, and manufacturing industries.

Q5: Which maintenance tips improve the longevity of custom steel grids?

A5: The maintenance tips that improve the longevity of custom steel grids include regular cleaning, inspections, and reapplication of coatings.