(3432 products available)

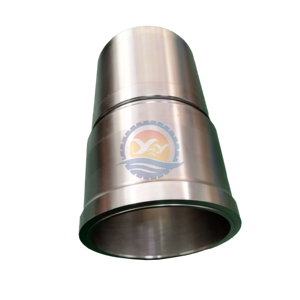

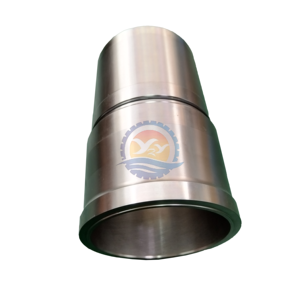

A cylinder liner is a part of an engine block that creates a cylindrical shape for the piston to move up and down. It is also known as a cylinder sleeve. The liner protects the engine block from wear and tear caused by the constant movement of the piston. It is a vital part of the engine because it helps maintain compression and friction reduction, enabling the engine to run smoothly.

While the cylinder liner is not visible externally, it is a crucial part of the engine. There are different types of Cummins engine parts cylinder liners, each with its advantages and suitability for different engine models.

Wet Cylinder Liners

Wet liners are installed in holes that penetrate deep into the engine’s cooling system. The cooling water surrounds the wet liners, allowing them to absorb excess heat from the engine and release it to the water. Wet liners are easy to remove and replace, making them ideal for engines that experience wear and tear.

Dry Cylinder Liners

Dry liners are not in direct contact with the engine’s cooling water. A small gap between the dry liner and the engine block allows for heat transfer. The space is filled with a thermal-conducting material to facilitate the process. The water may be close to the outer wall of the liner, but the liner is not in direct contact with the cooling water. Because the dry liner is not directly in contact with the engine's cooling system, it can cause overheating. They are more difficult to install and remove compared to wet liners.

Fired Cylinder Liners

Fired liners are used in engines where the combustion process happens inside the liner. The liner absorbs heat from the combustion process and transfers it to the engine's working fluid, which is air in this case. Fired cylinder liners are usually used in high-pressure engines.

Non-firing Cylinder Liners

Non-fired liners are used in engines where combustion occurs outside the liner. Like fired liners, non-firing liners can also be used in a cummins 6bt engine parts. Non-firing liners are used in engines where the working fluid is water.

The choice of cylinder liner depends on the engine model and its design. However, wet liners are the most preferred because of their durability and ease of maintenance.

Manufacturers usually indicate a number of specifications to help buyers understand the features of a given Cummins cylinder liner.

Size

The cylinder liner comes in different sizes depending on the make of the engine. It is crucial to determine the size of the cylinder liner when replacing it. Using a liner that is too small or too big will compromise the performance of the engine.

Material

As mentioned earlier, the cylinder liner is mostly made from iron. However, some manufacturers offer liners made from composite materials. These liners are suitable for high-performance engines.

Texture

Cylinder liners are available in both smooth and textured options. Textured liners offer better grip for the piston rings and are more popular among engine parts manufacturers.

Coating

Some liners come with a coating to reduce friction. The coating also protects the liner from wear and tear. It increases the lifespan of the cylinder liner.

Weight

Cylinder liners are available in different weights. Heavier liners are able to withstand the pressures of high-speed engines. However, they are not suitable for engines that require quick acceleration. Liner weight is an important specification for manufacturers to consider when sourcing liners for resale.

Maintaining Cummins engine parts cylinders is vital if users want to prolong the lifespan of the engine and prevent costly repairs. Here are some maintenance tips.

Regular inspection

It is important to regularly inspect the cylinder liners for signs of damage. Early detection of wear and tear can help prevent further damage. During the inspection, check the cylinder head gaskets for leaks.

Use quality engine oil

Using the recommended engine oil for the Cummins engine parts cylinder head will lubricate the liners and reduce friction. This prevents damage and wear and tear. The engine oil also protects the liners from rust.

Regular engine maintenance

Regular engine maintenance will ensure that all parts of the engine are working well. If the engine is overworked, it will cause damage to the cylinder liners. Replace engine air filters and spark plugs at the recommended time to prevent strain on the engine.

Maintain proper coolant levels

The coolant helps to regulate temperature during engine operation. Low levels of the coolant will cause the cylinder liners to overheat. Regularly check the coolant levels to ensure that they are adequate.

Choosing the right Cummins cylinder liner for a specific engine requires careful consideration of several factors. Here are some tips to ensure the correct selection:

Replacing the cylinder liner of a Cummins engine is a complex task that typically requires a good understanding of engine mechanics. It is also recommended to use specialized tools. However, here is a general guide on how to replace the Cummins engine parts cylinder liner.

Tools and Materials Required

Step-by-Step Guide

Q1: How Can a Liner Wear Measurement Gauge Be Used to Determine Cylinder Liner Wear?

A1: A liner wear measurement gauge can assess the condition of cylinder liners by measuring their internal diameter. It determines wear by comparing actual measurements to original specifications. Significant deviations indicate liner deterioration, affecting performance and efficiency. The gauge provides precise data for informed maintenance decisions.

Q2: What Are Some Tips for Installing Cylinder Liner Kits?

A2: When installing Cummins cylinder liner kits, ensure proper liner cleaning, cooling system maintenance, and alignment. Follow torque specifications and service manual instructions. Use quality parts and lubricants. Adhere to recommended procedures and safety measures. Take time to avoid errors. Thoroughly inspect components before installation. Ensure proper engine preparation and cleanliness.

Q3: What Is the Role of Cylinder Liners in Engine Performance?

A3: Cylinder liners are crucial in determining engine performance and longevity. They provide a smooth surface for piston movement, minimizing friction and wear. Liners maintain compression, ensuring efficient fuel combustion. They also transfer heat to the cooling system, preventing engine overheating. Durable liners withstand combustion forces, contributing to engine reliability.

Q4: What Are the Common Causes of Cylinder Liner Damage?

A4: Several factors can damage cylinder liners. Abrasive particles in the oil or air can cause wear. Poor lubrication leads to friction and premature liner failure. Overheating weakens liners, while chemical corrosion from additives or impurities deteriorates material integrity. Design flaws and manufacturing defects make liners vulnerable to damage.