Introduction to CSM 40 Rubber

CSM 40 rubber, known for its exceptional chemical resistance and durability, is a high-performance rubber material extensively used in various industrial applications. Composed mainly of chlorosulfonated polyethylene, it stands out due to its strength, flexibility, and resilience in challenging conditions. This makes it particularly suitable for environments that demand reliability and longevity.

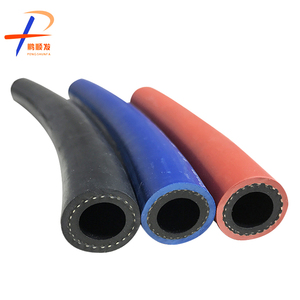

Types, Features, and Functions of CSM 40 Rubber

CSM 40 rubber comes in several forms that cater to diverse needs across multiple industries. Here are the notable types and their distinctive features:

- Sheet Form: Ideal for applications requiring large surface areas, easily customizable for thickness and dimensions.

- Tape: Excellent for sealing applications, providing a convenient and easy-to-use solution for repairs and insulation.

- Extruded Profiles: Available in various shapes and sizes, these can fit specific mechanical requirements for gaskets and seals.

- Molded Parts: Engineered for intricate designs and shapes, suited for specific applications such as automotive and aerospace components.

The key features of CSM 40 rubber include:

- Chemical Resistance: Highly resistant to oils, solvents, and acids, making it suitable for harsh environments.

- Weather Resistance: Excellent protection against ozone and UV exposure, ensuring longevity outdoors.

- Temperature Stability: Provides reliable performance across a wide temperature range, from -40°C to +100°C.

- Flexibility: Maintains its flexibility even at low temperatures, ensuring performance in challenging conditions.

Applications of CSM 40 Rubber

CSM 40 rubber serves a broad spectrum of applications across different industries due to its unique properties. Some notable applications include:

- Automotive Industry: Used for seals, gaskets, and hose linings, reducing the risk of leakage and ensuring optimal performance.

- Construction: Ideal for roofing membranes and outdoor installations, providing effective protection against weather elements.

- Aerospace: Employed in components exposed to extreme environments, balancing weight and strength.

- Oil and Gas: Perfect for pipelines and seals, offering resistance against harsh chemicals and oils.

Advantages of Using CSM 40 Rubber

Utilizing CSM 40 rubber in your projects comes with numerous advantages:

- Durability and Longevity: Its robust nature ensures extended service life, reducing the need for frequent replacements.

- Cost-Effective: While it may have a higher initial cost compared to standard rubber, its durability translates to long-term savings.

- Enhanced Safety: By resisting degradation, CSM 40 rubber contributes to safer operational environments, minimizing the risk of failures.

- Versatility: Its adaptability across numerous industries makes it a go-to choice for various applications, ensuring compatibility.

In summary, CSM 40 rubber is a superior choice for industries requiring a robust, chemically resistant material that provides excellent performance under diverse conditions. Its wide range of forms and applications paired with notable advantages make CSM 40 rubber an optimal solution for enhancing operational efficiency and safety.