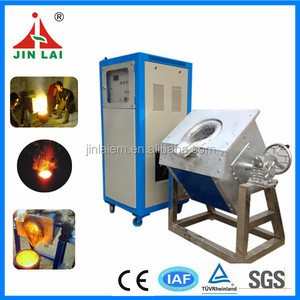

Introduction to Crucible for Melting Brass

A crucible for melting brass is an essential tool for metalworking and casting operations. Designed to withstand extreme temperatures, these crucibles are ideal for hobbyists and professionals looking to melt brass efficiently. Brass, an alloy primarily composed of copper and zinc, is favored in various applications due to its durability and malleability. A high-quality crucible ensures the melting process is safe, efficient, and effective, enabling users to achieve their desired results with ease.

Types of Crucibles for Melting Brass

When selecting a crucible for melting brass, it's important to consider the different types available, each suited for specific melting processes. Here are the main types:

- Graphite Crucibles: Known for their excellent thermal conductivity and resistance to thermal shock, graphite crucibles are ideal for brass melting. They can handle high temperatures without breaking down.

- Ceramic Crucibles: These crucibles provide excellent heat retention and are commonly used for melting brass in furnaces. They are less expensive but may not last as long under extreme conditions compared to graphite.

- Metal Crucibles: Often made from steel or cast iron, these crucibles are particularly strong and durable. They can withstand high temperatures but may require additional care to prevent erosion.

- Silicon Carbide Crucibles: Highly resistant to thermal shock, these crucibles are great for repeated use in intense conditions, making them a favorite among metalworkers.

Applications of Crucibles for Melting Brass

The crucible for melting brass is versatile and finds applications in various fields, ensuring its importance in both small and large-scale operations:

- Jewelry Making: Artisans use brass to create intricate designs, and crucibles allow them to melt and reshape the metal effectively.

- Mold Casting: Brass can be molded into various shapes using casts, requiring dependable melting tools like crucibles to achieve the right temperature.

- Repair Work: In repair shops, melting brass is essential for fixing parts, and having the right crucible ensures quick and efficient repairs.

- Metalworking Education: Hobbyists and students engage in learning processes that involve melting and casting brass, making crucibles crucial for educational purposes.

Features and Advantages of Crucibles for Melting Brass

Understanding the features and advantages of a crucible for melting brass can help users make informed purchasing decisions:

- High Temperature Resistance: Crucibles are designed to withstand temperatures exceeding 1000°C, essential for melting brass effectively.

- Durability: Most crucibles are built to last, resisting wear and tear, which ensures they remain functional for multiple sessions.

- Ease of Use: Designed for convenience, these crucibles usually come with ergonomic features making them easy to handle during melting processes.

- Consistent Melt Quality: A well-made crucible heats evenly, providing a uniform melt of brass, crucial for achieving the desired casting properties.

- Safety Features: Many crucibles are designed to minimize spills and reduce the risk of accidents during the melting process, enhancing user safety.