Introduction to Copper Spot Welder

A copper spot welder is an essential tool in the manufacturing and repair industries. It utilizes the electrical conductivity of copper to create strong and durable welds on various materials, particularly metals. The versatility and efficiency of copper spot welders make them indispensable for businesses engaged in metal fabrication, automotive repairs, and assembly line production.

Types of Copper Spot Welders

There are several types of copper spot welders available on the market, each tailored for specific welding applications:

- Manual Copper Spot Welders: These welders require operators to manually position and activate the welding process. They are ideal for small workshops and intricate projects.

- Automatic Copper Spot Welders: Designed for high-volume production, automatic welders enhance speed and precision, reducing the need for human intervention.

- Pneumatic Copper Spot Welders: Using air pressure, these welders provide added control in applying pressure, making them suitable for delicate metal components.

- Portable Copper Spot Welders: Compact and lightweight, these welders are perfect for fieldwork and smaller operations requiring mobility without sacrificing functionality.

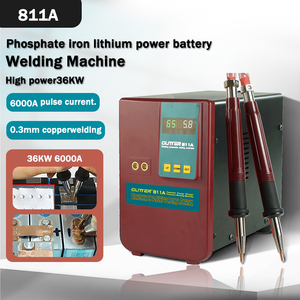

Function and Feature of Copper Spot Welder

Copper spot welders perform the critical function of joining metal components securely without the need for additional materials such as fillers or adhesives. The standout features include:

- High Temperature Resistance: Copper has a high melting point, allowing for effective welding without damaging adjoining materials.

- Quick Operation: Minimal setup and welding time facilitate efficient workflows in busy manufacturing environments.

- Energy Efficiency: Copper spot welders are designed to consume less energy while delivering optimal welding performance, contributing to cost savings.

- Adjustable Welding Parameters: Many models come with customizable settings for voltage and time, ensuring suitability for various metal types and thicknesses.

Applications of Copper Spot Welder

The versatility of copper spot welders extends across numerous industries, providing solutions for various applications:

- Automotive Industry: Essential for bodywork, frame assembly, and component connections.

- Manufacturing: Used in the production of electronic devices, appliances, and machinery, ensuring robust connections that withstand stress.

- Construction: Employed for joining metal frameworks and structural components, enhancing building integrity.

- Artistic Metalworking: Favored by artists and craftsmen for creating intricate metal sculptures and unique repairs.

Advantages of Copper Spot Welder

Utilizing a copper spot welder offers distinct advantages that enhance operational efficiency and product quality:

- Strong Welds: Produces robust joints capable of withstanding significant loads and stresses, ensuring longevity.

- Minimal Distortion: The localized heating minimizes thermal distortion, preserving the shape and integrity of components.

- Low Maintenance: Designed for durability, copper spot welders require less upkeep compared to other welding apparatus.

- Cost-effective: Reduced material usage and energy consumption leads to lower operational costs, making them economical for businesses.