(100962 products available)

There are about five main types of copper 70 which are based on their uses and composition. They include the following:

This is the most common brass used and is mainly because it is easy to machine. Also, it has good corrosion resistance. The 30% zinc in this alloy increases strength and hardness.

Often called Cupronickel 70 this alloy has excellent wear and corrosion resistance in marine environments Also, it retains its strength at elevated temperatures. It is primarily used in ship parts, offshore oil rigs, and marine hardware.

It contains about 0.8% phosphorus and is used where resistance to wear, fatigue, and corrosion is fundamental. In addition, it has excellent spring properties. Common applications include electrical connectors, springs, and components used in harsh environments.

This is a copper-zinc alloy with about 70% copper and 30% zinc. It offers good corrosion resistance and workability. Common applications for this alloy include Pipes, fittings, and general engineering. They are often used where moderate strength and good corrosion resistance are required.

This is the most common brass used and is mainly because it is easy to machine. Also, it has good corrosion resistance. The 30% zinc in this alloy increases strength and hardness.

Copper 70 has some distinct features that make it applicable in many environments. They have high corrosion resistance, thermal and electrical conductivity, and malleability.

The 30% zinc contents provide high resistance to galvanic corrosion in seawater and acidic environments. This makes it a preferred option for marine and industrial applications.

Copper 70 usually has higher strength than pure copper. This is due to the zinc addition. Zinc improves mechanical properties such as wear resistance. Copper-nickel-silicon alloys are also heat-treated to provide high strength and rigidity.

Seventy percent copper usually has lower conductivity compared to pure copper. However, it still supports heating and cooling applications adequately.

Although stronger than pure copper, Copper 70 is still malleable enough for fabrication into complex shapes. This includes bending, and machining without cracking or breaking.

When selecting copper 70 for a project, one should factor in the alloy's specific applications, availability, and compatibility with other materials. Hence, these are the main things to consider:

Consider the specific requirements of the application. For marine environments, look for copper-nickel-silicon or CuZn30 brass for their superior corrosion resistance.

Depending on the application, one may need to consider tensile strength, hardness, and wear resistance. Copper 70 alloys offer a good balance for structural and mechanical components.

Copper 70 is available in forms such as sheets, bars, tubes, and customized parts. The most common forms include rods, sheets, and tubes. Therefore, ensure the supplier offers the suitable form for the specific application.

If other materials are to be used in conjunction with Copper 70, ensure they are compatible. This applies especially when used in jointing or welding applications.

Certain industries such as aerospace and marine have strict material regulations. Copper-nickel-silicon alloys meet such standards. When buying in bulk, ensure the materials comply with applicable industry standards.

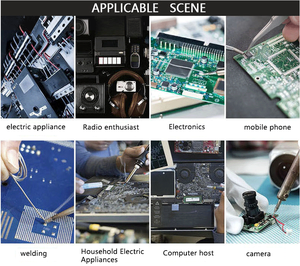

Copper 70's versatile properties make it ideal for use in a variety of industries. The prominent usages include the following:

Its high corrosion resistance makes Copper 70 suitable for use in shipbuilding, boat manufacturing, and offshore oil rigs. In the marine industry, Copper-nickel-silicon alloy is used to make pipes and other parts that always exchange fluids in seawater.

High thermal and electrical conductivity makes Copper 70 a preferred option in the electrical and electronic industries. Phosphor bronze for instance is used to make electrical connectors, sensors, switches, and other components that require reliable electrical conductivity.

Its wear and corrosion resistance make Copper 70 ideal for parts exposed to harsh environmental conditions. These parts include radiators, heat exchangers, and other critical automotive components. PB 70 is commonly used in automotive components like bronze bushings, springs, and electrical connectors exposed to high temperatures.

Copper 70's aesthetics, durability, and workability make it ideal for architectural applications like roofing, cladding, and decorative elements. Moreover, Copper-zinc alloys are commonly used in plumbing, piping, and building fixtures where corrosion resistance is fundamental.

In industrial machinery and equipment, Copper 70 is used in components usually exposed to friction and wear. For instance, parts in heavy machinery, gears, and bearings. Phosphor bronze is also used in gears, bearings, and other components requiring high durability and low friction.

Proper care and repair are crucial for maintaining the integrity and appearance of copper 70 over time. Maintenance also increases the lifespan of this alloy and keeps it functional in its environment. Below are some maintenance and repair tips for different applications:

To avoid copper 70 from tarnishing and developing corrosion, clean it regularly. Use mild soap and water for cleaning followed by a gentle scrubbing with a non-abrasive brush or cloth. For heavy deposits of tarnish, a vinegar and salt solution can be used. Rinse well and dry immediately to avoid water spots.

Applying wax or a dedicated copper protective spray can help inhibit oxidation and tarnishing. This is mostly used in architectural and decorative applications where appearance is critical. In marine environments, anti-fouling paint or other protective coatings can be used to guard against biofouling and corrosion.

Regularly inspect parts that see physical wear or are exposed to harsh environments. This allows one to identify signs of wear, corrosion, or mechanical failure early. Look for scratches, pits, discoloration, or structural damage. Catching issues early allows for timely intervention.

Small areas of corrosion or oxidation can usually be addressed with sanding or wire brushing. This should be followed by recoating the area with protective material. Welding or brazing might be necessary for more extensive damages. Only use methods compatible with copper 70 alloys to avoid compromising structural integrity.

For heavily worn or damaged parts, replacement might be the most practical option. This includes components that have lost structural integrity or are repeatedly failing. Ensure replacements match the original specifications to maintain performance and compatibility.

A1. Copper 70 refers to an alloy that contains approximately 70% copper. Depending on the type, it may contain zinc, nickel, silicon, and phosphorus. This alloy is known for its unique properties. They include high corrosion resistance, good mechanical strength, and excellent electrical conductivity.

A2. The primary component of Copper 70 is copper itself. It is typically accompanied by 30% zinc or other metals like nickel and silicon for copper-nickel-silicon. Phosphor bronze contains about 0.8% phosphorus which improves corrosion resistance and enhances mechanical properties.

A3. Copper 70 has several distinctive properties. It has a conductivity of 66% IACS, good corrosion resistance, and moderate strength. Additionally, it is malleable, durable, and easy to recycle. This makes it an environmentally friendly option.

A4. Copper 70 is employed in a wide variety of industries. It is commonly used in the marine industry for parts, like shafts, heat exchangers, and marine hardware. In the automotive industry, it is used in radiators and electrical components. Other uses include architectural features and industrial machinery.The above help reduce maintenance costs while increasing the value of the items.

A5. Maintenance of copper 70 depends on the application. Routine cleaning with mild soap and water helps prevent tarnishing and corrosion. In marine environments, one should regularly inspect and replace protective coatings like anti-fouling paint. In industrial uses, carry out regular inspection and minor repairs to extend the life of the components.