(312 products available)

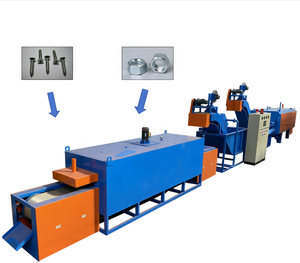

A furnace for hardening metal continuously is what is meant by a continuous hardening furnace. It makes use of moving belts, which are sometimes referred to as quenching conveyor hardening furnace systems, to steady workpieces while they are being put through heat treatment. A thoroughly heat-treated object, such as a steel object, will have a more angled, complex pattern applied to its surface. Such a process is essential for achieving a premium level of toughness and, in many cases, corrosion resistance.

This kind of large-scale industrial furnace usually offers the following operations for metal workpieces, in this order: heating, soaking, quenching, tempering, cooling, and unloading. Because it can transport parts through a combination of heat treatment processes, it is valuable for factories dealing with large continuous volumes of metal parts.

Types of continuous hardening furnaces include the following:

Mesh Belt Furnaces

Heavy-duty conveying media are used in this kind of continuous hardening furnace to transport items through heat zones. Typically, the heat source in a furnace of this kind will be either an electric or gas blower. Withstanding temperatures as high as 2000degF, the conveyer is often made of stainless steel, which also has a high tolerance for extreme heat. Hardening furnaces that use a mesh belt will typically have a quenching tank that uses water. This is because items need to be rapidly cooled to increase their hardness.

Chain Votex Furnaces

When an item requires a higher load chain to convey it through different heat treatment zones of the continuous hardening furnace, a chain link belt is used instead of a mesh. This is typically used for larger parts like gears, which may weigh up to 10 pounds per square foot. Higher strength steel are used to create the chain links to improve load capacity. Withstanding abrasion better than a mesh link, this also lengthens the lifespan of the links. These links are often easier to clean, and the individual links can be replaced if they become worn out instead of the entire chain links like in a mesh chain.

Screw Conveyors

This kind of transport mechanism utilizes a helical screw to move items consistently through different zones of the conveyor. It is more suitable for holding workpieces that need to stand up to lateral forces, such as those on which machining is taking place. In addition, this is more capable of handling the accumulation of particulate matter, which may require heat treatment in square or round containers, moulds, or vessels.

Salts Furnaces

Salt quench furnaces have the added advantage of utilizing multiple salts in their setup. Apart from being able to temper simultaneously inside the furnace, the hardness obtained from salt quenching will typically be higher than that from water quenching. This is because the salt will create a brine-like solution that is a better transfer medium for quenching. The drawback of this kind of furnace is that it is more complicated to set up and maintain. Operating costs for this kind of furnace may also be higher to manage the salts used for them.

The hardening furnace has various specifications depending on the model and type that affect the ability and use. When buying, it is essential to discuss the specifications of the continuous hardening furnace with the manufacturer and ensure they align with the industrial needs.

Temperatures

The temperature of a continuous hardness furnace varies with the model, type, and brand. However, the temperature must reach an adequate level to increase the hardness of materials and metal. For instance, the induction hardening furnace can achieve a temperature of up to 1,500 degrees Celsius.

Dimensions

The continuous hardening furnace usually has a huge dimension since it's used in industrial settings. The dimension of the furnace will affect its capacity and the volume of the materials it can handle. For example, some furnaces measure 12 meters in length and around three meters in width and depth.

Power consumption

The power consumption of the furnace can be one or two megawatts, for it to maintain the desired temperature and atmosphere during the hardening process.

Materials

The furnaces are built with materials like alloy steels, high-temperature ceramics, or refractor materials that can withstand the greater temperatures.

Hardening method

The continuous hardening furnace uses distinct methods depending on the type. For example, the induction furnace utilizes electromagnetic induction as a heat source.

The right maintenance and care enable the continuous hardening furnace to function throughout its lifespan. It reduces the possibilities of breakdowns and repair needs. Ordinarily, the maintenance of such hardening equipment requires a professional service technician. Nevertheless, here are some suggestions and tips for care to keep the equipment working well.

Regular inspections

It's necessary to have scheduled inspections of the hardening furnace. It allows the technicians to quickly identify and detect any possible issues that might need repair or attention.

Calibrate control systems

Checking and calibrating the controls and monitoring systems is essential now and then. It ensures that the temperatures and atmospheres are maintained consistently throughout the process, delivering accurate results.

Cleaning

The furnaces usually have debris and deposits of materials that need to be removed after some time. Cleaning the hardening furnace improves the efficiency and performance of the equipment. It also minimizes the risk of contamination that affects the quality of materials.

Maintain lubrication

Regularly greasing and lubricating the moving parts in the continuous hardening furnace prolongs its lifespan. It also minimizes the possibility of abnormal wear and tear, which often leads to equipment breakdown.

Continuous hardening furnaces are essential pieces of equipment for various industries. In general, they are mainly used in the metalworking and manufacturing industry to improve the physical properties of metals and achieve a more consistent and uniform microstructure.

When choosing an industrial hardening furnace, buyers need to consider various parameters to ensure they purchase a model that fits their specific requirements.

Heating and working temperature

This is the range of temperatures a continuous hardening furnace is capable of achieving. Buyers need to get a model that can achieve the temperatures required for the materials they intend to use in their industrial processes.

Production capacity

This is the amount of material the equipment can process in a given timeframe. It is usually measured in kilograms per hour or similar metrics. Buyers need to consider the maximum amount of material the company needs to process within a specific time frame so as to get a model with an appropriate size.

Energy source and efficiency

Continuous hardening furnaces use various energy sources such as electricity, gas, or oil. Buyers need to consider the suitability of the energy source for their environment and its energy efficiency to ensure economical and sustainable use.

Control system

Hardening furnaces typically come equipped with advanced control systems to manage temperature, time, atmosphere, and other parameters. Buyers need to consider the user interface and functionality of these control systems to ensure they can easily operate and monitor the furnace.

Design and structure

A continuous hardening furnace design and structure will affect its performance, reliability, and maintenance. Buyers need to assess the materials, manufacturing process, and design of the furnace to ensure its durability and stability.

Additional components and functions

Some continuous hardening furnaces may be equipped with additional functions and accessories, like quenching and tempering furnaces. Buyers need to consider their specific requirements and the suitability of these additional functions to see if they can enhance the efficiency of their industrial processes.

Q: What materials can be processed in a continuous hardening furnace?

A: Continuous hardening furnaces are primarily designed to process various steels and alloys.

Q: Can a continuous hardening furnace be used for bulk production?

A: Yes, one of the key advantages of continuous hardening furnaces is their capacity for bulk production.

Q: What are the trends in the development of continuous hardening furnaces?

A: The trend of continuous hardening furnaces is toward energy-saving, environmental protection, automation, and intelligence.

Q: Can continuous hardening furnaces be integrated with other processing units?

A: Yes, in some industrial production lines, continuous hardening furnaces can be integrated with other processing units, such as continuous casting, forging, and machining units to form a complete production line.

Q: What are the advantages of continuous hardening furnaces compared with intermittent furnaces?

A: Continuous hardening furnaces have greater productivity, faster processing speeds, and higher degrees of automation than intermittent furnaces.