(8957 products available)

Concrete poles are long cylindrical structures commonly used to support power lines, telecom lines, and other types of overhead lines.

Depending upon the needs of the customers and the end applications, concrete poles can be manufactured in various shapes, sizes, and designs. The following is a comprehensive list of the commonly used types of concrete poles:

Circular concrete pole

An experimental comparison of existing material and processing technologies used to create concrete poles demonstrates that circular concrete poles outperform other pole designs in structural efficiency. Uniform cross-sections throughout the pole assist distribute weight and stress uniformly. Cast-in-place and spun-cast concrete are widely used manufacturing methods for circular concrete poles. The latter creates high-strength poles with smooth finishes through centrifugal force during casting.

Tapered Concrete Poles

The tapered concrete pole's design reduces wind resistance while maintaining stability through a wide range of heights. The poles' bases are sturdy, and their tops are light, which makes installation and transportation easier. Tapered poles provide an unobstructed view and space beneath them, making them ideal for rural areas. Their lightweight construction limits the use of concrete and expenses. Also, to satisfy diverse demands, tapered concrete poles can be made in a variety of materials and sizes.

Square concrete pole:

Square concrete poles, or quadrilateral pillars, have four equal sides. They are simpler and more economical to build than tapered poles, but their wind resistance at higher heights is a notable downside. Although square concrete poles are fashionable, they take up more room. Their corners could make them hazardous in locations with a lot of traffic.

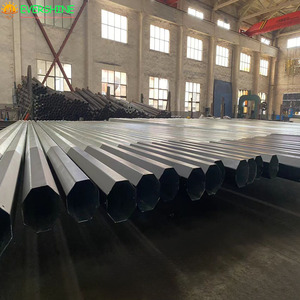

Octagonal concrete pole

The eight-sided octagonal concrete pole offers both aesthetic appeal and functional efficiency. Its geometric shape provides a modern look, making it suitable for urban environments and contemporary architectural settings. Wind resistance is better compared to square poles, which enhances stability, especially in harsh weather conditions. Due to its efficient material usage, the octagonal concrete pole frequently strikes a balance between the squared-off forms and the more refined tapered silhouettes. In addition, just like tapered cement poles, custom designs, materials, and sizes are available options for octagonal concrete poles.

Length

The length of concrete poles may greatly vary according to their uses and requirements. Typically, the lengths for concrete poles range from 1 meter to 12 meters. For instance, the utility concrete pole length is usually between 9 to 12 meters, while shorter lengths may be applied for fencing or decorative purposes.

Diameter/Shape

Concrete poles possess various shapes, such as circular, square, and octagonal. Normally, the diameter and cross-section of concrete poles will depend on their applications. For example, concrete poles with a circular cross-section and a diameter of about 20 to 30 centimeters are commonly employed as lighting or utility poles.

Strength

Strength is another key factor of concrete poles, which is usually measured by the characteristic compressive strength. It is represented by the letter ''f'' followed by a suffix ''ck'', and higher the concrete pole strength can bear greater loads and provide increased stability. Concrete poles are generally recognized as grade 30, 35, or 40 in the metric system. For example, concrete poles with a strength of 40 can support heavy structures:

Grade 30:Strength is 20 MPa or more.

Grade 35:Strength is 25 MPa or more.

Grade 40:Strength is 30 MPa or more.

Pre-Stressed or Reinforced

Concrete poles can be categorized into prestressed and reinforced. The latter incorporates steel bars into the mixture to enhance its strength and resilience. Prestressed concrete poles are manufactured with high-tension steel, enhancing their capacity to withstand bending and cracking.

Surface Finishes

Concrete poles may possess various surface finishes. Smooth finishes may offer a traditional appearance, while textured finishes provide a more anti-slip feature.

Proper maintenance of concrete poles is crucial to ensuring they possess long-lasting service while minimizing potential hazards. Luckily, the maintenance and care for concrete poles is usually simple to complete, as they require little to no maintenance. However, some routine inspections can aid in determining their status and usage to avoid any possible issues.

One of the most common methods of maintenance for concrete poles is cleaning. It's a common practice for peoples to use high-pressure water blasters or hoses to remove any debris, dirt, or buildup. This helps not only to maintain the appearance but also to reveal potential damages that need to be addressed.

Another essential aspect of the upkeep of concrete poles is conducting regular inspections. It is suggested that users check the poles routinely and look for any possible signs of damage, such as cracks, chips, or wear and tear. If finding any issues, solutions should be taken immediately to ensure the safety of all users.

Concrete light poles have a wide range of applications in various industries, thanks to their sturdy pole-like structure and multifunctional characteristics.

Demand analysis

When buying concrete poles, buyers need to conduct a demand analysis to determine the quantity and specifications of poles required for their projects. This includes factors such as the scale of the project, the use of concrete poles, and the time frame for purchasing.

Supplier selection

Buyers need to choose a reliable supplier. Consider the supplier's experience in concrete poles manufacturing, production capacity, quality control system, and after-sales service. Conduct a comprehensive evaluation of several suppliers and select a supplier that meets the needs of the project.

Product quality

Business buyers need to ensure the quality of the concrete poles they purchase. Select concrete fence posts and utility poles that comply with relevant standards and have good quality. Pay attention to whether there is a certification for the product, such as ISO certification, etc., to ensure the quality of the product.

Price negotiation

Business buyers need to conduct price negotiation with suppliers. Understand the market price level of concrete poles through multiple channels and negotiate prices with suppliers based on factors such as purchasing quantity, long-term partnership, and project requirements. Ensure that the price is reasonable while meeting the project's needs.

Logistics and distribution

Since concrete poles are bulky goods, the logistics and distribution arrangements are necessary. Coordinate with the supplier and logistics company to ensure timely and safe delivery of the goods.

Establishment of cooperative relationship

Business buyers have the opportunity to establish a long-term cooperative relationship with suppliers. This allows buyers to enjoy more favorable prices and better services in future purchases. At the same time, maintaining good communication and cooperation with suppliers helps to ensure the quality and stability of the product supply.

Q1: What is the average life span of a concrete pole?

A1: Concrete poles can last longer than wood when properly maintained. The typical life span of concrete utility poles can be 50 years or more.

Q2: What are the environmental benefits of concrete poles?

A2: Concrete poles have several environmental benefits. They are made of recycled materials and can be recycled at the end of their life. They are energy efficient. Concrete has a high thermal mass that helps regulate temperature by absorbing heat during the day and releasing it at night, reducing the need for air conditioning. Concrete poles also need less energy for maintenance and replacement compared to other materials.

Q3: What are the top six manufacturers of concrete poles?

A3: The top manufacturers include China National Building Material Company Limited, Jidong Development Group Company Limited, Anhui Conch Cement Company Limited, Holcim, CRH, and HeidelbergCement.