(20372 products available)

Coir fiber for coconut is extracted from the husk of coconuts. It has two primary types, which are defined by the maturity of the coconut from which the fiber is extracted.

Brown Coir Fiber

Brown coir is derived from fully mature coconuts. These coconuts are left to ripen on the tree before the fibers are extracted. Since the fibers come from mature fruit, they tend to be longer, stronger, and stiffer. Also, they have a greater diameter and density, which contributes to their toughness. Their hardness makes them suitable for heavy-duty applications like mats, ropes, and brushes. Moreover, they are extensively used in horticulture as biodegradable plant pots, garden twine, and coir geotextiles.

White Coir Fiber

White coir is extracted from the husk of an immature coconut. The fiber is lighter, softer, and more delicate during extraction. It is ideal for products requiring finer and softer fibers. Therefore, white coir is often used in upholstery, mats, and ropes. Great care is taken to ensure that the extraction process does not damage the fiber’s quality.

Coir fiber is a natural and versatile material. It is created from the outer husk of the coconut. It has the following key features:

Water Absorption

Coir fiber has high water retention capacity. It can absorb and hold substantial quantities of water. This makes it ideal for growing plants in dry soils. Coir products such as grow bags and pots for plants ensure proper moisture. They do it without waterlogging and choking the roots.

Biodegradability

Coir fiber is 100% natural and organic. This means the product eventually breaks down after a certain amount of time. It does not contribute to long-term environmental pollution when disposed of. Hence, it is a sustainable alternative to synthetic materials. Such features are particularly important to eco-conscious consumers or businesses.

Renewable Resource

The production of coir fiber comes from coconuts and the outer husk that is removed during the processing. Coconuts can grow in a lot of regions across the world. As a result, they provide a consistent and long-term source of the material. Since the fiber is obtained from the husk, there is also minimal wastage in the entire process.

Durable and Stiff

Coir fiber’s durability is notable. It can withstand heavy use and is weather-resistant. Users also note that it does not rot easily even when left outdoors in moist conditions for long periods. All these features contribute to its strength and make it highly applicable in doormats, rugs, and ropes. Over time, it retains its stiffness. This makes it useful in products like brushes and buffers where firmness is a key requirement.

Biological Activity

Coir fiber has a slightly acidic pH. This helps in suppressing certain diseases that affect plants. It also provides an ideal substrate for beneficial fungi and bacteria to thrive. These two factors help in improving soil structure and enhancing plant growth. Consequently, it boosts the health of the plants and the quality of the produce.

Coir fiber has many wide-ranging applications for different industries. Following are some of its uses across various industries:

Agriculture and Horticulture

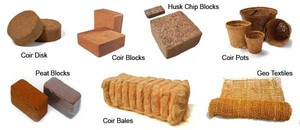

Coir fiber’s major application is in the manufacturing of grow bags and pots. These are used in the cultivation of plants and in gardening practices. It is widely used as a growing medium because it improves soil structure. It also helps in retaining moisture while promoting good drainage. Such plants have longer growth periods because the coir helps them grow strong and survive the long journey to clients or to retail outlets.

Garden Décor

Coir fiber is used to make coir moss poles. These poles are provided to climbing plants as support while the plants grow. When the plants reach full height, they will have dense and beautiful foliage all over the pole. It is also used to make coir liners for wire frames. These liners are used to create hanging baskets and artificial coco planters. They are ideal for both professional and do-it-yourself gardeners because they add more character to gardening and planting. All these products also have a very natural appearance that suits every gardening enthusiast.

Home Décor and Furnishings

Coir fiber is typically used to manufacture coir doormats, rugs, and carpets. Grown into strong, durable, and hardwearing mats, coir fiber makes a sustainable and natural doormat. Considering its water and mold resistance, coir fiber also manufactures rugs that survive in high-traffic and adverse weather conditions. Other products such as cushions and pillows also incorporate coir fiber to provide firmness and support.

Automotive and Industrial Applications

Coir fiber is commonly used in the automotive industry to manufacture composite materials for seat padding, door panels, and headliners. Since they are lightweight yet strong, these composite materials improve fuel efficiency while also providing good insulation properties. In industrial applications, coir fiber is used to make ropes, twine, and brushes. These are characterized by strength and durability and can be used for many purposes.

Erosion Control

Coir geotextiles and coir nets are used for erosion control in many civil engineering and landscape restoration projects. These are installed on slopes and riverbanks to provide retention and protection of soil. They promote the growth of vegetation. The vegetative growth then eventually stabilizes the soil and improves ecological health. Since the coir fibers degrade over time, they provide a temporary stabilization. Eventually, they integrate with the natural soil and roots of plants.

Biotechnology

Coir fiber has very high lignin content. This makes it suitable for the production of biocomposites or even biofuels after going through the requisite processes. In biotechnological applications, coir fiber supports fungal growth as well. This is especially for fungi used in bioremediation processes to degrade pollutants in contaminated soils.

Buyers can consider the following factors when choosing coco products:

Coconut origin

Coir fiber is normally imported from tropical countries where coconuts thrive. These countries include Thailand, India, and Sri Lanka. Therefore, buyers can take advantage of this knowledge and select coir based on the reputation of the country for producing certain types of fiber. For instance, coir from India is renowned for producing superior-quality brown coir. It is ideal for heavy-duty applications.

Degree of maturity

As mentioned earlier, brown coir comes from fully ripe coconas while white coir is from half-baked ones. Each type has its own texture, length, and strength. Hence, buyers need to consider these aspects and choose the one that will satisfy the intended purpose. For example, those intending to use the fiber for horticultural applications should go for brown coir. It is more resilient and has better water-retention capabilities.

Processing methods

Coir fiber processing methods have a huge impact on the quality and characteristics of the final product. Coir that undergoes manual extraction processing is usually of higher quality. This is because the manual work is careful not to damage the fiber’s quality. On the other hand, fiber that’s extracted using machines is sometimes damaged or shorter. Therefore, to ascertain the quality of the fiber, buyers should inquire about the processing method used. This is to ensure that they get coir that has the desired level of fineness, length, and strength.

Coir fiber specifications

Coir fiber comes in two main forms, namely, bristle coir and mattress coir. Bristle coir consists of long and stiff fibers sourced from the outer husk of really mature cocon nuts. It is ideal for tough and heavy-duty applications like manufacturing ropes and mats. Conversely, mattress coir comprises short and fine fibers that are soft and springy. It is extracted from the inner layer of the husk of fully mature as well as semi-mature coconuts. This type of coir is mainly suited for moderate uses. It incorporates cushions, mattresses, and other upholstery items.

Coir fiber color

Coir fiber normally comes in two major colors, which are brown and cream. Brown coir is coarser and stiffer. It makes it ideal for heavier applications such as flooring mats and ropes. On the other hand, cream coir is softer and finer. It is more suitable for lighter uses. These include doormats and potting mixes. Brown coir also comes with better durability and more water retention capability than cream coir.

Fiber quality

When buying coir products in bulk, buyers should prioritize quality above all else. Quality significantly impacts coir fiber’s longevity, usability, and effectiveness. Buyers should examine fiber to find out whether it has any signs of impurities or whether it has any visible defects. Good-quality coir fiber is normally free from dirt, decaying matter, or any form of synthetic material inclusions. Also, it has uniformly distributed fibers that are of the same length and diameter. They don’t have varying sizes or thicknesses. Such fibers tend to compact evenly as a result. This gives a pleasing aesthetic look. More importantly, it offers even support and functionality throughout the fiber’s usability period.

Coir fiber is a highly valued and eco-friendly product that is incorporated into a wide range of industries. It fits perfectly in the textile and agriculture industries as well as into home and spaces. Other uses are for erosion control and in the automotive industry. The agriculture and gardening industry uses coir in doormats and rugs. The agriculture and gardening industry dominates coir fiber application. It uses the fiber to manufacture grow bags, pots, and as a growing medium. These offer stellar features like optimum moisture retention and improved soil aeration. Since coir fibers in mats, rugs, and carpets have aesthetically pleasing looks and sturdy build, they have found their way into home décor. In the automotive realm, coir composites are used for parts such as seat linings. Coconuts also control erosion in civil engineering projects. They stabilize soils by promoting the growth of vegetation. Every application enjoys the durability, versatility, and biodegradability that coconut coir fibers come with. It helps protect the environment, especially for individuals or businesses that are eco-conscious.

Brown coir usually comes from fully matured coconuts that have been left to ripen on the palm tree. On the other hand, white coir is extracted from the fibers of coconanut that are still in their immaturity phase. Coir fiber has many benefits. It is strong, water-resistant, and highly buoyant. Because brown coir undergoes the least processing, it tends to be thicker and stiffer. This makes it suitable for heavy-duty applications like doormats and ropes. White coir, on the other hand, is finer and softer. It makes it ideal for lighter applications. These include plant pots and mats.] Both types of coir have unmatched durability. They offer a natural alternative to synthetic fibers and contribute to eco-friendliness.

Buyers need to pay attention to the certifications that the coir fiber comes with. For instance, coir that’s certified organic ensures that no synthetic chemicals were used in its production. Fair Trade certifications also have such coir as supporting farmers’ labor rights and providing them with better working conditions. Buyers also need to look into sustainability certifications like the Global Organic Textile Standard. Such certifications provide a standard that’s sought after by eco-conscious brands. Also, certifications, such as the FSC label, offer proof that the coir is ethically sourced from responsibly managed plantations. Coir that’s certified biodegradable and compostable offers guaranteed end-of-life options. This can promote a circular economy. Certificates to assess the quality of coir and its fibers are also available. These include ISO and DIN standards for fiber length and strength.