(6508 products available)

Coated steel gratings are a type of metal product used for flooring, walkways, and platforms with a lot of foot traffic. They are made of steel bars that cross each other at right angles, forming a grid-like surface. They provide support and allow light, air, and water to pass through. Coated steel gratings are durable, long-lasting, and corrosion-resistant. Coated steel gratings come in different types and sizes, all of which are listed below:

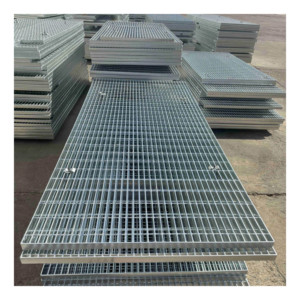

Plain Steel Grating:

These are the most basic type of coated steel grating. They have an open design that provides maximum airflow and light. They are used in industrial settings, platforms, and walkways. They are made from hot-rolled steel and are very strong and long-lasting. They are also known as heavy-duty floor grating because they can support a lot of weight. They are used in the manufacturing industry, mines, and coal storage areas. They can be galvanized or coated with powder paint to prevent rusting. Galvanized steel coated grating is suitable for wet areas, while powder-coated steel grating is used in dry areas.

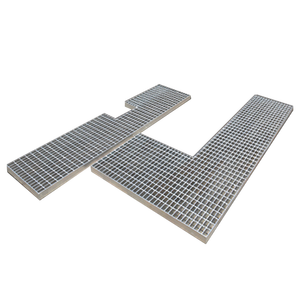

Trench Grates:

Trench grates are a type of coated steel grating used to cover and protect drainage trenches or channels. They allow water to flow freely into the trench while providing a strong, slip-resistant surface for pedestrians or vehicles. Trench grates help prevent debris from entering drainage systems and clogging them.

Bar Grating:

Bar grating is made up of load bars running parallel to the direction of traffic. This type of steel grating is often used in industrial applications. It is classified into two types: I-bar grating and rectangular bar grating. I-bar grating is lighter than the rectangular bar and is used in applications where weight reduction is important. It has a modern look and is easy to clean. It is also used in industrial applications. It is made from aluminum, steel, or stainless steel. It is more expensive than I-bar grating but provides more strength. It is used in applications where high load-bearing capacity is required.

Press Lock Grating:

Press-lock grating is a type of coated steel grating that is locked into place without welding. It has a high-density design that provides slip resistance and strength. It is used in applications that require a solid, durable walking surface.

Coated steel grating has various applications in outdoor and industrial settings. The features of coated steel grating offer a solution to many challenges in construction and other industries. These are the functions of coated steel grating:

Load bearing

Coated steel grating is used in walkways, platforms, and industrial flooring. It can bear heavy loads from foot traffic and machinery. The strength of the steel and the design of the grating bars offer load-bearing capability. Coated steel grating has high strength and durability. They provide long-term support in industrial settings.

Traction

Coated steel grating provides traction in walkways and platforms. The gaps in the grating prevent slipping even when the surface is wet. Traction is important in platforms and walkways in industrial settings. It ensures the safety of workers and prevents accidents.

Drainage

The open design of coated steel grating allows for easy water drainage. It prevents the accumulation of water on walkways and platforms. Good drainage reduces the risk of slip and fall accidents. It also protects the coated steel grating from corrosion. The accumulation of water on steel grating can lead to rusting or corrosion.

Ventilation and light

Coated steel grating is used in industrial settings to allow air circulation and natural light. The open design of the grating permits air and light to pass through. This is important in areas that require ventilation and natural lighting.

Debris control

The gaps in the coated steel grating trap debris and dirt. This makes it easy to clean the grating and maintain it. Some coated steel gratings are used in gardens and parks. They prevent leaves and small particles from blocking drainage channels.

Accessibility

Coated steel grating is used in most industrial settings. It provides a stable surface for workers to walk on. Coated steel gratings are also used in the construction of ramps. They support people with disabilities and those using wheelchairs.

Coated steel gratings are versatile and widely used products in different industries and applications. Here are some common usage scenarios:

Walkways and Pedestrian Paths

Coated steel grating is used in walkways and pedestrian paths in public parks, commercial buildings and industrial sites. They provide a durable and slip-resistant surface for pedestrians.

Parking Lots and Driveways

Coated steel grating is used in parking lots and driveways to create a strong and stable surface for vehicles. The grating allows water to drain through and reduces puddles and skidding.

Bridges and Overpasses

Coated steel grating is used in bridges and overpasses to form the road deck and footpath surfaces. The open structure reduces wind load and allows rainwater to pass through.

Industrial Flooring

Coated steel grating is used as industrial flooring in factories, warehouses and refineries. It can withstand heavy loads, chemicals and high foot traffic. The grating also allows dust and spills to drop through for easy cleaning.

Cooling Towers and Water Treatment Plants

Coated steel grating is used in cooling towers and water treatment plants. The grating is corrosion-resistant and allows air and water to pass through. It is also used as platforms, walkways and access covers in these areas.

Power Plants

Coated steel grating is used in power plants. For example, it can be used in coal handling areas, turbine halls and boiler rooms. The grating provides a strong and safe walking surface for workers.

Heavy Machinery Areas

Coated steel grating is used in areas with heavy machinery like workshops, garages and construction sites. The grating can support the weight of machinery and allow fluids to drain through.

Marinas and Docks

Coated steel grating is used in marinas and docks. It allows water to pass through and reduces the buildup of water and algae. The grating also provides a non-slip surface for boats and people.

Landfills and Waste Management Centers

Coated steel grating is used in landfills and waste management centres. The grating is durable and can withstand harsh conditions. It is used in walkways, platforms and access areas.

When choosing the ideal steel grating for a project, several factors need to be considered. The load capacity is one of the factors. This is the amount of weight the grating can support. Heavy-duty applications need a load-bearing steel grating that can support pedestrian traffic or machinery. Coated aluminum grating is available in different load ratings, which are class C, class D, class E, and class heavy-duty.

The material and coating are also important to consider when choosing a coated steel grating. Steel and aluminum are the most common grating materials. They offer high strength and are lightweight. Steel and aluminum coated steel gratings are corrosion-resistant and suitable for different environments. The application and environment also influence the selection of coated steel grating. They are used in various applications, such as flooring, platforms, walkway, and drainage. The different environments include chemical, marine, and industrial.

The project requirements and specifications also influence the choice of coated steel grating. They include dimensions, load capacity, and environmental factors. The project budget is also important. It includes the cost of purchasing the grating and the installation cost. Some coated steel gratings are more expensive than others, and some require more installation time.

Lastly, the supplier's reputation and customer service are important when buying coated steel grating in bulk. It is important to choose a supplier with experience in the industry and offers quality products. They will deliver the products on time and offer support when needed.

Q1: Why is galvanized steel grating coated instead of just using bare steel?

A1: Coating provides additional protection against rust and corrosion in specific environments. It also prevents the hot-dipped galvanizing process from changing the appearance of the grating. The coating helps the coated steel grating to last longer in harsh conditions.

Q2: How can one tell if a grating has been properly coated?

A2: Quality control can be done through tests like adhesion tests and thickness measurement. Visual inspection can also be done. The coating should be even, smooth, and of the required thickness. No flaking or peeling should occur.

Q3: Can coated steel grating be used in areas with high temperatures?

A3: Yes, many types of coatings can tolerate high temperatures. For example, powder coatings can withstand temperatures of up to 200 degrees Celsius. At no point should the coating melt or become soft.

Q4: Is it possible to repair damaged coated steel gratings?

A4: Yes, it is possible to repair damaged grating. For small areas of damage, it is possible to touch up the coating. This helps to restore the protection and bond the coating to the grating. Coating repair kits can be used for the process.

Q5: What are the factors to consider when choosing the right type of coating for a project?

A5: Consider the environmental conditions like temperature and presence of chemicals. The desired appearance of the grating should also be considered. Look at the required durability and abrasion resistance of the coating. Consider the budget and project cost. Lastly, consider the installation requirements.