(213 products available)

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

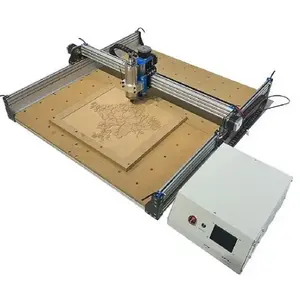

A CNC (Computer Numerical Control) router is a computer-controlled cutting machine. It is used for cutting various hard materials, such as wood, composites, aluminum, steel, plastics, and foams. The CNC router cuts these materials following a predetermined cutting path. The CNC router 8080 gets its name from the table size, which is 800mm by 800mm. This machine is used for accurate and precise manufacturing projects. The table size of the 8080 router may vary, but the most common sizes are 800x800mm, 1000x1000mm, 1200x1200mm, and 1300x1300mm.

There are many different types of CNC routers, including:

Specification: CNC 8080 router is a type of CNC router machine with an 8000 x 8000mm working area. It has a 270-degree rotation spindle, a 0.01mm positioning accuracy, a 0.02mm repositioning accuracy, a 0-24000 RPM spindle speed, and a 380V/50Hz 3-phase 30kW spindle power. The CNC 8080 router machine is controlled by a DSP A11 control system, which is an independent and powerful digital control system that supports offline operation through the U disk. It also has an 8-zone vacuum table to allow for secure material hold-down during machining, and it is compatible with a variety of software, such as Artcam and Type3. It is primarily used for cutting, engraving, and milling applications on various types of material, such as wood, MDF, PVC, acrylic, and aluminum.

Maintenance:

Small CNC router 8080 machines are used in a variety of applications across numerous industries. Here are some common usage scenarios for these machines:

Creating intricate designs, carving, engraving, and cutting various materials like wood, plastic, and metal for signs, artworks, and decorations.

Producing prototypes, models, and mock-ups for product design, development, and testing in industries like manufacturing, automotive, and aerospace.

Teaching CNC programming, design, and manufacturing concepts in schools, technical institutes, and training centers using small CNC routers for hands-on learning.

Creating custom furniture pieces, cabinets, and millwork by cutting, carving, and engraving wood, MDF, or plywood to achieve unique designs and finishes.

Precious Metal Carving with CNC router 8080 is a great way to make jewelry. It is a precise method of carving that requires no physical effort. The CNC jewelry machine is computer-controlled, and the design is transferred from the computer to the machine to create beautiful pieces of jewelry.

Precise cutting, engraving, and etching of metals like aluminum, brass, and steel to produce components, parts, and decorative elements for metalworking, jewelry making, and architectural industries.

Small CNC routers are used in the medical industry to produce medical devices and components. CNC machines are used to cut, drill, and mill materials with high precision, ensuring the quality and accuracy of the final products.

Creating handmade items, personalized gifts, and DIY projects by cutting, carving, and engraving materials like wood, acrylic, and leather to unleash creativity in arts and crafts.

Producing electronic enclosures, robotic parts, and prototypes for electronic devices by cutting, drilling, and milling materials like plastics and PCBs with precision and accuracy.

Small CNC routers are used in the textile industry to manufacture clothing and accessories. They can cut and engrave fabrics with great precision, enabling the production of intricate designs and patterns. CNC routers are also used to make accessories such as handbags, belts, and wallets.

When choosing a suitable CNC router for an application, it's important to carefully consider the following factors.

It is important to choose a suitable CNC router based on the type and thickness of the material that needs to be processed. Different materials and thicknesses require CNC routers with different specifications, such as spindle power and feed rate, to ensure effective processing.

The working area size of the CNC router should be selected according to the size of the workpiece to be processed. It is recommended to choose a machine with a slightly larger working area than the maximum size of the workpiece to allow for margin during processing.

The control system and software of the CNC router are also essential. When selecting a machine, it is necessary to check whether the control system is easy to operate and whether the software is compatible with the processing requirements to ensure the smooth processing of the workpiece.

The spindle is the main component of the CNC router, which is used to rotate cutting tools. There are several types of spindles available, such as water-cooled and air-cooled spindles. It is important to select the appropriate spindle according to the processing requirements, for example, the required cutting power, speed range, and tool compatibility.

The rigidity and precision of the CNC router are important for the quality of the processed workpiece. When selecting a machine, it is necessary to consider the machine's rigidity, stability, and accuracy to ensure the high-quality processing of the workpiece.

When choosing a CNC router, it is also essential to consider whether the machine has some extra features, such as an automatic tool change system or a dust collection system. These additional features can enhance the efficiency of processing and improve the working environment.

Q1: What are the advantages of using a CNC router 8080?

A1: The CNC router 8080 has numerous advantages. It offers precise and consistent cutting. It enables automation and can make complex designs with ease. Besides, the 8080 model comes with a large working area that allows for batch processing.

Q2: What materials can a CNC router 8080 cut?

A2: CNC routers can cut a wide range of materials, including wood, plastic, acrylic, PVC, double-color board, soft metal like aluminum, copper, and brass alloys. The ability to cut these materials makes it suitable for many industries.

Q3: Is the CNC router 8080 easy to operate?

A3: The CNC router 8080 is not difficult to operate since it has a well-known controller. However, the mastery of the machine takes time and practice. Beginners will need to get adequate training to get the hang of the machine.

Q4: How fast does the CNC router 8080 cut?

A4: The cutting speed of the CNC router 8080 depends on a few factors, such as the type of material being cut and the bit being used. However, in most cases, the speed can vary between 2,000 mm/min to 15,000 mm/min.