(797 products available)

The realm of precision cutting and engraving has been revolutionized by the advent of CNC laser XYZ technology. This category encompasses sophisticated machinery designed for detailed work on a plethora of materials. The core of these systems lies in their ability to manipulate materials with extreme accuracy, guided by computer numerical control (CNC).

CNC laser engravers are versatile tools that cater to various applications. From creating intricate logos to detailed drawings and precise text on materials like wood, acrylic, and leather, these machines are integral to industries ranging from manufacturing to design. While CO2 lasers excel with non-metal materials, fiber laser engravers extend the capability to metals, enabling both engraving and cutting of thin metal sheets.

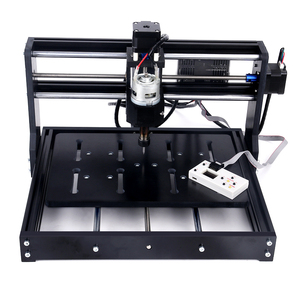

A typical CNC laser cutter comprises several key components: a controller board, a motor, a cooling system, and a laser head. The cooling system, essential for maintaining the machine's performance, may employ water or air-based methods. Notably, many units come with protective covers to shield users from harmful ultraviolet rays during operation, reducing the need for additional protective gear.

The specifications of a CNC laser machine vary, with engraving areas ranging from 300 x 200mm to 1,300 x 900mm. The weight of these machines can also vary significantly, influencing their portability and space requirements. Laser power is another critical factor, with options available from 40w to 300w. This power directly correlates with the machine's engraving and cutting speeds, which can range from 350mm/s to 2,000mm/s for engraving, and 35mm/s to 1,000mm/s for cutting. Resolution capabilities span from 1,000DPI to 4,500DPI, ensuring clarity and detail in the finished product.

CNC laser systems are typically accompanied by proprietary software, though they maintain compatibility with various third-party software solutions. This flexibility allows users to choose their preferred software environment, such as LightBurn or LaserGRBL, to manage their engraving and cutting projects effectively.

Selecting the appropriate CNC laser equipment hinges on understanding the specific needs of your projects. Factors such as material type, thickness, and the desired precision should guide the decision-making process. While browsing the extensive collection on Cooig.com, consider the technical specifications and features that align with your operational requirements.