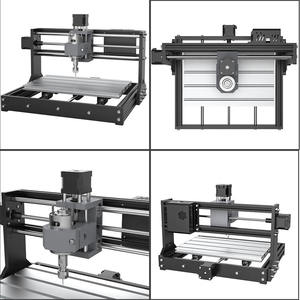

CNC Laser Cutting Machine DIY: Introduction

The CNC laser cutting machine DIY is a revolutionary tool designed for precision, efficiency, and versatility in the hands of creators and manufacturers alike. This advanced technology enables users to cut various materials with utmost accuracy, making it an essential equipment for hobbyists, small businesses, and large manufacturers. The ability to control laser cutting through computer numerical control (CNC) allows for intricate designs and patterns that traditional cutting methods simply cannot achieve. Whether you are creating custom parts, intricate designs, or artistic pieces, a CNC laser cutting machine offers unmatched precision.

CNC Laser Cutting Machine DIY: Functions and Features

The versatility of CNC laser cutting machines is defined by their numerous functions and features. Here’s a closer look at what makes these machines such a vital asset:

- Precision Cutting: Achieve intricate cuts that are impossible with manual tools.

- Material Versatility: Cut through a range of materials including wood, acrylic, metal, and fabric.

- Speed and Efficiency: Faster production times on projects without compromising quality.

- Automation and Control: Easily program designs and adjust settings for different materials and thicknesses.

- Minimal Waste: Efficient cutting patterns reduce scrap material.

CNC Laser Cutting Machine DIY: Applications

The applications of CNC laser cutting machines are vast and varied, spanning multiple industries and creative fields:

- Manufacturing: Producing parts and components for machinery.

- Signage: Creating detailed custom signs for businesses and events.

- Fashion: Designing intricate cut patterns in textiles and leather.

- Art and Decor: Making artistic pieces, sculptures, and personalized gifts.

- Engineering: Prototyping for product designs and mechanical parts.

CNC Laser Cutting Machine DIY: Advantages

Investing in a CNC laser cutting machine DIY offers numerous advantages that enhance productivity and creativity:

- Cost-Effective: Reduces labor costs and time associated with manual cutting methods.

- Scalability: Ideal for both small-scale DIY projects and large production runs.

- Improved Quality: Consistent and high-quality finishing on all cuts.

- User-Friendly: Modern interfaces and software make it accessible for beginners.

- Sustainability: Enhanced efficiency leads to lower energy consumption and material waste.