(5377 products available)

All machines used for the processing of gears are referred to as CNC gear grinders. A CNC bevel gear grinder is used to grind bevel gears, while a CNC hob gear grinder is used for hobbing gears. The distinction between the two lies in how the gear is produced and what machine is used to produce it. Bevel gears usually work at angles and do not have parallel shafts. Hobbing gears have teeth similar to that of a worm, and the gears usually have parallel shafts. CNC bevel gear grinders are more complicated and high-tech than hob gear grinders.

Hobbing is a technique used to cut out gears from large pieces of metal. The method is usually fast and produces a large volume of gears. CNC hobbing gear grinders can produce different types of gears, such as:

Bevel gears are usually produced using a CNC bevel gear grinder. As discussed above, they are high-tech machines usually used for high-precision materials. Bevel gears are cut at an angle. They have an edge that resembles a cone and are used in machines where shafts are at right angles. They help change the direction of movement. There are different types of CNC bevel gear grinders:

Some crucial components of the CNC gear grinder are as follows:

Machine effectiveness:

An essential metric in determining how well a equipment operates is its functioning. For CNC gear grinders, this productivity level ultimately determines how many gears it can rough and finish per unit of time. Machine efficiency may vary depending on the model and gear specifications.

Gearing thrust:

For CNC gear grinders, thrust refers to the axial forces and moments produced during gear cutting operations. Every gear-cutting machine generates its unique set of working thrusts. Hence, every CNC gear grinder has its specified value of optimal thrust for efficient functioning at its designated levels.

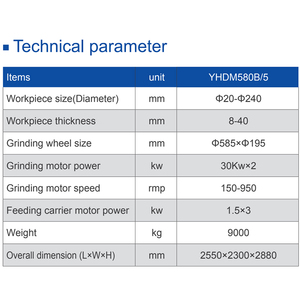

The range of Gear sizes:

One crucial factor that distinguishes one CNC gear grinder from another is the size range of the gears. Manufacturers typically specify a minimum and maximum size they can handle. Businesses focus on this specification since it directly links their product's market usability.

The level of Automation:

Some machines have a higher degree of automation than others, which affects the process. A CNC gear grinder with high automation will probably have more automatic loading and unloading features than machines with less. This greater level of automation allows operators to cut more complex and bigger gears continuously without having to stop for manual assistance.

Accuracy up to Microns

Some CNC machines can operate within millimeter measurements. However, some top models provide precise machining down to one-thousandth of a milled cube or micron. Such precision is necessary for industries where components must have an accurate fit for them to serve their intended purposes. Machines that offer this level of accuracy typically attract higher prices because their parts are more advanced and sophisticated in design.

The longevity of a machine may be determined by routine maintenance and repair costs. Regular checks and minor fixes can help prevent more severe ailments that may need more critical, expensive surgeries. Gear-grinding machines also require routine care so they may continue working well after going through much-use stress.

Generally speaking, CNCs need regular mixed lubrication applications to keep kicking smoothly through consistently oiled parts. Set schedules for these oiling events based on how frequently people use these machines. In addition to lubrication routines, it's equally essential to schedule inspections to check for any signs of abnormal wear, tear, temperature rise, or noise.

Some grinding parts may need periodic honing of their surfaces. This can be done by removing any soft abrasives that have cemented onto them and re-establishing a fresh grind layer. Always replace damaged parts rather than attempting to repair them, as this is probably going to be the only way of ensuring that what we've just exchanged is as good as new.

Follow oiling and replacement schedules advised by manufacturers of specific models, as they may differ from others in their preference or need for a more frequent form of care than some. Repair experts should also be called up whenever any doubts arise during inspection routines. This is important because misdiagnosis could end up harming machines further beyond what we did.

CNC gear grinding machines have different applications depending on the industries and field. In the manufacturing industries, they are used to make or manufacture big gear cutting products. They are also used to produce special gear types and double crown pinion gears.

Automotive manufacturers use the CNC gear grinder machine to make different parts of vehicles efficiently and with a high level of precision. They value its faster production time and use it to improve the overall performance of the vehicles they are making or manufacturing. The result is a vehicle that is durable and has high-quality and smooth-running components.

The aerospace industry relies heavily on the CNC gear grinder machine. It is used to produce different pinion and crown gear types used in the aerospace industry applications. The same drill applies to the marine industry. The machine produces the gear types used in different marine equipment and devices.

The CNC gear grinder has also made it easy to manufacture power generation devices and equipment. It grinds and produces the gears used in wind, marine, hydroelectric, and solar power generation systems' machines and protective devices.

Other industries that use the CNC gear grinding machine to make or manufacture gears include the construction, robotics, and medical industries. In the construction industry, the gears produced with the grinder machine are used in machinery like excavators, reducers, loaders, and hoists. The gear types made with the grinder machine are also used in high-precision medical devices. They include MRI machines, blood purification machines, and ventilators. Robots use the gears produced with the grinder machine to withstand heavy loads and give flexibility.

For businesses looking to invest in a cnc gear grinding machine, a few factors must be looked into so that what is purchased is high-performing, durable, and cost-effective.

The Workpiece's Size and Weight

Consider the workpiece's size and weight, as this determines the optimal machine dimensions and load capacity. A mismatched machine may cause operational inefficiency or safety hazards.

Machine Drivetrain

The drivetrain influences how a gear grinder machine works. Consider factors such as load capacity, power requirements, and maintenance needs. Select a suitable drivetrain that meets operational demands and aligns with long-term goals.

Grinding Precision and Tolerance Levels

Precision is an important factor, as the tolerances that a machine can achieve directly impact the quality of gears produced. Prioritize machines that offer the desired precision and can meet specific tolerance requirements for the intended application. Investing in a machine with higher grinding precision can help improve product quality and reduce rework.

Automation and Software Features

When it comes to automation and software, the features help determine a machine's ease of use, productivity, and consistency. Select a machine with suitable automation and software capabilities to address particular production needs and workforce availability.

Grinding Wheel Compatibility

A gear grinder machine's grinding wheel can affect performance. Choose a machine that is compatible with the kind of grinding wheels that will be used. Consider factors such as size, shape, and material to ensure proper functioning and optimize grinding efficiency.

Quality of Machine Components

Consider the machine's components, like the spindle, bearings, and drives. The performance and durability of a gear grinder depend significantly on the quality of its parts. Choose machines with components manufactured to high standards to ensure reliable operation and minimal downtime.

Q: What are the current trends in gear grinding technology?

A: The CNC gear grinder is witnessing several trends, including the adoption of automation and AI, increased interest in environmentally friendly methods, and the desire for high-precision and high-efficiency machines.

Q: What are the disadvantages of a gear grinder?

A: Gear grinding machines are quite expensive, and their high costs can be prohibitive for companies. Also, the quality of gears processed by gear grinders can be excellent, which is excessive for some applications. Moreover, the operation of a gear grinder requires specialized skills, which can be a challenge for some manufacturers.

Q: What materials can a gear grinder process?

A: Generally, it is high-carbon steel, alloy steel, tool steel, hard aluminum alloy, etc., which have high strength and are not easy to break.

Q: Do gear grinders have different power options?

A: Yes. Gear grinders are available in hydraulic, pneumatic, and electric models, with electrically powered ones being the most common.