(1341 products available)

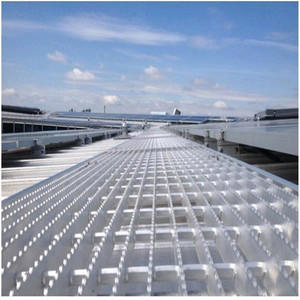

A cheap steel grating is a load-bearing platform that is used in various applications as a walking surface. It has multiple uses in construction and industrial areas, such as an accessible walkway, flooring, stair treads, platform, and ramp surfaces. Steel grating has high strength and corrosion resistance, which makes it a popular choice in many applications. It comes in different types, such as pressure-locked grating, welded grating, and riveted grating.

Welded grating is made of crossbars and bearing bars that are welded together to form a grid pattern. They are used in heavy-duty applications and have high strength and durability. Pressure-locked grating is made using a locking machine that applies pressure to fuse the bearing bars and crossbars together. They have a smooth surface and are used in applications where a non-slip surface is required. Riveted grating is made of bearing bars and crossbars that are riveted together using steel rivets. They are used in applications where a lightweight grating is required.

Steel gratings are also classified based on the shape of the bearing bars. They include; I-shaped grating, serrated grating, and slip-resistant grating. I-shaped grating has a simple and modern design that makes it aesthetically pleasing. They are used in applications where light-weighting and structural integrity are required. Slip-resistant steel grating has a textured surface that prevents slipping and is used in applications where safety is a priority. They include industrial areas with high traffic and water.

Steel grating is also classified based on the type of steel used. They include galvanized and mild steel grating. Galvanized steel grating is steel that has been galvanized to prevent corrosion and rust. It is popular due to its lightweight nature and high strength. Steel grating is an important part of construction and industrial applications due to its versatility and multiple applications. It is used as a walkway in construction sites, and it is also used in industrial areas for drainage.

Heavy Load-Bearing Capacity:

Steel grid flooring is ideal for applications requiring a strong load-bearing capacity. Steel is an incredibly durable and robust material that can withstand heavy loads without bending or breaking. This makes cheap steel grating panels suitable for use in industries such as construction, manufacturing, and infrastructure. They are used in constructing walkways, platforms, and support structures that can support significant weight in traffic.

Slip Resistance:

Slip resistance is one of the most important features of grid flooring. Slip-resistant surface is crucial in environments where safety is a concern, such as industrial settings, factories, and commercial spaces. Steel grid flooring allows water, oil, and other slippery materials to drain through, reducing the risk of slips and falls.

Ventilation and Light Transmission:

Another important feature of grid flooring is that it allows air and light to pass through. This is beneficial in applications where ventilation and natural light are needed, such as in open-air spaces and agricultural settings. Steel grid flooring promotes airflow, reducing the buildup of moisture and creating a more comfortable environment.

Customization and Versatility:

Cheap steel grating comes in different sizes, shapes, and configurations to meet specific requirements. This versatility makes it suitable for various applications, from industrial settings to architectural projects. Grid flooring can be customized to fit different styles and design components, making it a flexible flooring option.

Corrosion Resistance:

Corrosion resistance is an important feature of steel grid flooring. Some steel grating, like galvanized steel grating, is coated with materials that provide protection from rust and corrosion. This is important in applications exposed to moisture, chemicals, and harsh environmental conditions. Corrosion-resistant steel grid flooring has a longer lifespan and requires less maintenance.

There are many applications of a cheap steel grating, including:

Walkways and Platforms

Steel grating is used in walkways and platforms because it is non-slip and safe. They are also used in industrial areas where workers walk often. Cheap steel gratings allow water to drain and reduce slip hazards. It is an excellent choice for walkways and platforms because it is safe, strong, durable, and low-maintenance.

Bridges

Steel grid decks are used on most bridges to make them lighter. The steel grid deck construction makes them safer and easier to maintain. The cheap steel grating allows water to flow through and helps keep the bridge deck clean by preventing water from pooling.

Architecture

In architecture, steel bar gratings are used for exterior facades, sunshades, and interior applications like stair treads and flooring. Cheap steel gratings are also used in architectural design because they are functional and allow designers to be creative. They come in different shapes and sizes and can be finished in many ways.

Drain Covers

Steel grate drain covers are cheap and durable. They are used in urban and rural areas. Steel grating covers are easy to install and maintain. They are also safe and can support different weights. Steel grid covers allow water to flow well and prevent debris from blocking the drain.

Heavy Equipment

Cheap steel grating is used in heavy equipment for traction, strength, and ventilation. They provide a non-slip surface for safe movement on equipment like cranes and construction machinery. Steel gratings are durable and require little maintenance. They also allow air to flow through and prevent overheating in machines.

Industrial Applications

Cheap steel grating is widely used in industry because it is strong and allows light and air to pass. They are used for stairs, walkways, work platforms, and machine surfaces. Steel gratings are slip-resistant and prevent accidents in industrial areas.

Load-bearing capacity and durability:

Consider the load-bearing capacity of cheap steel floor grates. This indicates how much weight the grid can handle without damage. Think about the durability of the grates. Galvanized steel or aluminum options resist rust and last longer under tough conditions.

Bar configuration and spacing:

Check the layout of the bars on the steel grid. Close bar spacing gives better support but reduces airflow and light. Wider spacing allows ventilation and illumination but must be suitable for the load. Choose the bar arrangement based on the required strength, airflow, and brightness.

Slip resistance and safety:

Evaluate slip resistance for safety. Look for steel grids with slip-resistant features like serrated bars or superior textures, especially in damp or industrial locations. Bar steel grates with good traction decrease accidents and are safer for high-traffic areas or locations with moisture.

Corrosion resistance and material selection:

Choose cheap galvanized steel grates for long-lasting performance in wet or chemical-rich environments. Consider the material properties and select high-quality steel that meets the environmental challenges to extend the lifespan of the grating.

Maintenance requirements and ease of cleaning:

Consider the upkeep needed for the steel grates. Select grates that are easy to clean and care for, especially in places with high dirt or debris levels. Cheap steel grating with low maintenance requirements saves time and expenses over its service life.

Aesthetics and finish options:

Look at the appearance of the steel grids. Select finishes and patterns that complement the surrounding design. While function is primary, the steel grates' visual impact should also be considered, mainly if they will be seen in public areas.

Installation requirements and customization:

Check the installation demands of the steel grids. Some may need special tools or skills, while others are simple to install. If specific dimensions are needed, consider customizing the steel grid to fit perfectly and meet all functional requirements.

Q1: How long will a galvanized cheap steel grating last?

A1: Galvanized cheap steel gratings last many years. Hot-dip galvanization forms zinc layers on steel, which acts as a barrier to water and oxygen. The layers have an anti-corrosion effect, and cheap steel grating rusts slowly when exposed to elements. Gratings last over 30 years in areas not heavily salted. In coastal areas where there's frequent exposure to salt water, galvanized gratings can last 15-20 years.

Q2: How is a cheap steel grating installed?

A2: Installation involves welding or bolting methods. Welded joints are continuous and strong, while bolted connections are quick and easier to disassemble. It's important to install galvanized cheap steel grating properly to maintain load-carrying capacity and safety.

Q3: What is the load capacity of cheap steel grating?

A3: Load capacity depends on factors such as thickness, mesh opening dimensions and support spacing. Manufacturers provide load tables to help select suitable steel cheap grating for specific applications and loads.

Q4: How is the steel grating maintained?

A4: Maintenance involves regular cleaning and inspections. Areas with welding spots, dirt or debris should be cleaned to prevent rust formation. Cheap steel grating should be inspected for signs of corrosion or damage, especially in high-traffic areas. This ensures structural integrity and longevity.

Q5: What are the types of steel used in steel grating?

A5: The common types include mild or low carbon steel, galvanized steel, stainless steel, and aluminum. Mild steel is cost-effective and has high strength. Galvanized steel offers anti-rust protection. Stainless steel provides superior corrosion resistance. Aluminum is lightweight and non-rust.