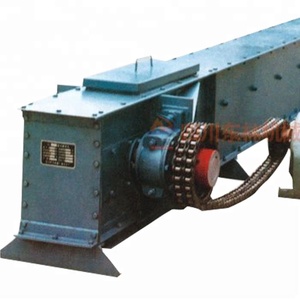

Introduction to Chain Redler Conveyor

The chain redler conveyor is an essential piece of equipment in the bulk material handling industry, designed to efficiently transport materials horizontally or at inclines using a robust chain system. This conveyor type is characterized by its durability, versatility, and efficiency, making it ideal for the transportation of granular and powdered materials such as grains, coal, and cement. Understanding its various types, features, and applications will highlight why the chain redler conveyor is a preferred choice for many industries.

Types of Chain Redler Conveyor

Chain redler conveyors come in multiple configurations to meet varying operational needs. Here are some common types:

- Standard Redler Conveyor: This free-flowing type is suitable for most bulk materials, offering a simple and efficient design.

- Heavy-Duty Redler Conveyor: Designed for the transportation of heavier materials, this type uses reinforced components to handle increased loads.

- Inclined Redler Conveyor: This configuration allows for the efficient transportation of materials at an angle, maximizing space and enhancing productivity.

- Vertical Redler Conveyor: Ideal for situations where a rapid elevation of materials is required, this type is often utilized in pits and silos.

Applications of Chain Redler Conveyors

The versatility of chain redler conveyors enables their use in a wide range of applications across various industries:

- Agriculture: Transportation of grains, feed, and fertilizers in farming operations.

- Cement Industry: Efficient movement of raw materials like limestone and clay to and from silos.

- Mining: Used for the safe and effective transport of mined materials such as ores and coal.

- Food & Beverage: Handling granulated materials and powders, ensuring hygiene and compliance with industry standards.

Features and Advantages of Chain Redler Conveyors

Opting for a chain redler conveyor comes with multiple advantages, making it an appealing choice for businesses looking for reliability and efficiency:

- Durability: Constructed from high-strength materials, these conveyors withstand abrasive environments and rigorous operation.

- Low Maintenance: Their robust design minimizes the need for frequent repairs, saving time and costs in the long run.

- Customizability: Many models can be tailored to fit specific applications, including adjustments in length, width, and incline settings.

- Efficiency: Designed for continuous operation, they facilitate high-volume material handling with minimal downtime.

- Safe Operation: Equipped with safety features to protect operators, these conveyors enhance workplace safety while handling bulk materials.