(1459 products available)

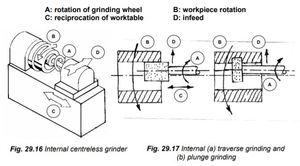

Centerless grinding machines function and look different from regular grinders. Typically, they come in two main types: Adjustables/Thrufeeders, which can easily be set up and used for various machining needs; through-feed centerless grinders and in-feed centerless grinders for processing different kinds of workpieces; and CNC centerless grinders that provide computer-controlled centering precision and automated operations.

The in-feeding system of in-feed centerless grinders usually has fixed jaws to help restrain and guide the workpieces. Other kinds of systems are magnetic chucks and air pistons, which press the workpiece against the grinding wheel.

Size capacity

S length capacity of a centerless grinder varies depending on the model. The average size capacities for different types are as follows:

Widths: 0.5 inch to 4.0 inches

Lengths: 1.5 to 12.0 feet for upender and 1.0 to 6.0 feet for through feed.

Power

The power of a centerless grinding machine usually falls between 2 to 15 kW. Different types of grinders have varied power ratings as follows:

In-feed centerless grinders usually have 10 kW power rating.

Through-feed grinders normally have 15 kW.

As the name suggests, upender models have lower power and they usually range from 4 to 8 kW.

Diameter capacity

The diameter capacity of a centerless grinder varies by the model and manufacturer. However, it generally ranges between 0.3 inches and 3.0 inches.

Many manufacturers have preferred the machine due to its low maintenance requirements. Nonetheless, some routine centerless grinder maintenance tips can ensure the machines run optimally for many years. They include:

Regular Lubrication

Regular lubrication is vital for the longevity of the grinding machine. It reduces normal wear and tear of moving parts and ensures smooth operation. Find the components recommended for lubricating by the manufacturer. Apply grease or oil as instructed during assembly or installation.

Daily Cleaning

Cleaning the daily coolant reservoir is crucial for optimal grinding machine operation. The user should empty, clean, and refill the reservoir before starting the grinding machine. This process helps remove any contaminants from the reservoir that can damage the pump or coolant system.

The centerless grinding machine has various applications in many industries. For instance, in the manufacturing industry, it's used to produce many products like axles, rods, spindle and dowels. Moreover, the machine is suitable for grinding different workpiece geometries.

The automotive industry primarily uses centerless grinders to process fuel injection pipes, hydraulic valve rods, pneumatic valve rods, precision spindle rods, multi-head telephone lines, auto parts, accessories, and safe locks.

As already mentioned, the machine is excellent for achieving higher productivity when processing many small-sized workpieces. Such tasks include machining bearing rings, bushings, washers, cutting tools, cartridges, rings, ammo, valve seats, and many more.

A_TRACE_Machinery_1.jpg

Another application of interest that stands out is the medical industry. Centerless grinders are commonly used to produce catheter bodies (extremely tight and slender tubing), guide wires, cannulas, handles for surgical instruments, orthopedic implants, and various precision instruments and implants.

The electronic and high-tech industries also use these machines to manufacture components like optical fibers, fiber optic needle wires, electrical connectors, wires, pins, shafts, and other intricate parts.

Finally, the aerospace industry has its fair share of applications for centerless grinders. Here, they are typically used to process various aircraft components, including landing gearstruts, turbine shafts, aircraft pins, and other precision parts that demand high accuracy and tight tolerances.

Business buyers need to consider different aspects when choosing centerless grinders for their specific purposes. Here are some factors that they should keep in mind:

Understand their needs

First of all, buyers need to determine their particular needs by asking themselves several questions. For example, what kinds of materials will the machines be used to grind? What are the diameters and lengths of the workpieces? Will they prioritize precision, efficiency, or flexibility? Once comprehending their specific applications, business buyers can choose centerless grinders that are suited to their needs.

Consider different types of centerless grinders

As mentioned above, there are several types of centerless grinders. Business buyers need to choose suitable machines according to their particular applications. They can also consider the advantages and limitations of different types of centerless grinders.

Assess grinding capacity

The grinding capacities of centerless grinders vary from model to model. Business buyers need to confirm that the maximum diameter and length are compatible with their workpieces. They should also pay attention to the grinding precision and ensure the machines can meet their tolerances.

Evaluate machine features

When choosing centerless grinders, business buyers need to pay attention to some features that may influence the performance and efficiency of machines. For example, the coolant systems of centerless grinders are important to control temperature and remove debris during the grinding process. Also, CNC centerless grinders can provide automation and enhanced precision, which are ideal choices for businesses requiring high-volume production.

Check the quality and after-sales service

Business buyers are suggested to choose reputable manufacturers that can provide reliable centerless grinders. Buyers can read reviews to learn about the quality of the machines and the manufacturer's service. It's also important to check the technical support and spare parts supply of centerless grinders. If necessary, buyers can ask manufacturers for references and then contact the references to ensure they are choosing the right manufacturer.

Q1: What materials can a centerless grinding machine process?

A1: Centerless grinders can process various materials, including metal alloys. Depending on the centerless grinder Machine's construction and specifications, some may not be unfazed when processing plastics, rubber, ceramic, and food-grade materials.

Q2: Can a centerless grinder process materials other than metal?

A2: Yes, some centerless grinders can process non-metal materials, such as plastics, rubber, ceramics, and even food-grade materials. Such as the in-feed centerless grinders can process non-metal materials such as rubber and plastic.

Q3: What is the typical lifespan of a centerless grinder machine?

A3: The machine's lifespan depends on the material's quality, construction, frequency of use, maintenance, and other environmental factors. Typically, a centerless grinder's machine's lifespan can range from 10-20 years or even more.