(1790 products available)

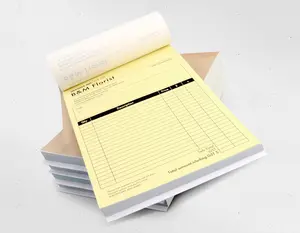

Standard Carbon Receipt Paper

The most popular and commonly used type of carbon receipt paper is standard carbon receipt paper. It emits carbon through the use of a thin carbon film between standard paper and the writing or printing medium. When pressure is applied through the use of a pen or printer, carbon is transferred to the paper located underneath it, making a copy of whatever is on the upper page. Standard carbon receipt paper is the most general type of carbon receipt paper, and it is often used for businesses and in industries like manufacturing, retail, and distribution for creating varied receipt copies, invoices, or work orders.

Multi-Part Carbon Receipt Paper

Multi-part carbon receipt paper is set up to help users make copies of various parts or leaves of a single document. It is mainly used in transaction documentation, where a single transaction would require different documentation by receipt or invoice. This kind of carbon receipt paper is available in dissociable sets consisting of different papers, and it can be constructed so that the copy can be made on more than one paper at a time, whether on the top paper or near the bottom. Multi-part carbon receipt papers are commonly used in fields that require more detailed accountability of sales, such as wholesaling, hospitality, and transportation.

Synthetic Carbon Receipt Paper

Synthetic carbon receipt paper is an alternative to the regular carbon receipt paper and is constructed from waterproof and tear-resistant synthetic materials. For optimal durability and longevity, this paper may be used for non-carbon copies by coupling it either with standard paper or synthetic material. Synthetic carbon receipt paper is most suitably applied when durability is necessary; in other words, the documents must stay readable for longitudinal periods of time. Examples of such a necessity could be shipments, legal documents, and other storage records in hostile environments.

Carbonless Receipt Paper

Carbonless receipt paper requires no carbon sheet for transfer, as carbonless receipt paper is often mistaken to refer to carbon receipt paper. Carbonless receipt paper makes use of pre-coated technology on the leaves, whereby contact or pressure on one inked leaf causes an ink transfer to another leaf underneath it. This type of receipt paper can be found widely in usage across many businesses since it doesn't come with as many concerns regarding carbon security as traditional receipt paper. However, the end-results can be similar, and the end-results can also be in multiple copies.

Retail and Point-of-Sale Systems

Carbon receipt paper is primarily used in the coding and decoding systems at retail, using standard carbon receipt papers. From sales items to purchases made and instructions to shoppers, the store keeps and issues a copy of every transaction made. It is necessary for the very important and enveloped economic operation of the retail sector that a copy of every transaction is onboarded, and that is where the carbon receipt plays its role.

Manufacturing and Industrial Settings

Carbon receipt paper is used widely in the manufacturing sector, where larger carbonless paper is applied to work orders, shipping notices, and production records. It may be necessary, especially in such areas, that information be duplicated without mistake, and carbon receipt paper serves to address this necessity. In production control and inventory management, several elements that need to be managed in businesses in their industrial environments cannot be effectively measured without using receipt papers.

Logistics and Transportation

In logistics and transportation industries, carbon receipt paper is primarily applied to bills of lading, waybills, and delivery receipts. Information transfer between various parts of a complex operation is vital, and accuracy is the most critical currency in its management. Multi-part carbon receipt paper presents itself here as an indispensable tool, allowing companies to prepare copies of shipment documents, give one to the driver, and fix one for their record and send the rest to the customer.

Service Industries

Carbon receipt paper is used in service-related industries such as hospitality and repairs and tracking invoices, work orders, and receipts. This paper helps in creating copies that are often easily and quickly accessed, which is required for better service provision without necessarily compromising the quality of the document produced. For industries where work carried out is at times documented in the form of invoices or receipts to consumers, the carbon receipt paper plays a very pivotal role.

Legal and Compliance Documentation

Legal practices must always maintain more than one version of documentation, whether it's contracts, agreements, or invoices. Carbon receipt paper is indispensable in the legal field to create and maintain accurate duplicates of a great number of legal documents. It is also indispensable for compliance records in industries that are highly regulated, where accurate documentation is crucial to ensure compliance with various laws and regulations in the industry. The durability of the documents maintained can affect the medium used; hence, in many situations, synthetic carbon receipt paper is required.

The basic function of carbon receipt paper lies in its ability to enable the user to create copies of documents. Whether used manually with a typewriter or in a printing system, or in the form of direct sales in which each sheet has to be lifted out to make one or two copies of that particular sheet of paper with a great amount of ink called carbon-inked paper placed on the underside of that sheet of paper, this special paper is also conductive and often semi-translucent. In receipt and other similar document generation systems, carbon receipt paper is usually placed between more usable sheets, which are often ordinary paper or in a carbon-less duplicate envelope. Each writing caused the upper paper to fragment, and carbon particles were thus transferred onto the sheet located just below it. It efficiently created one or more copies of the reports.

When choosing carbon receipt paper, there are certain aspects to consider based on several factors: usability, functionality, and durability. These aspects impact the usability, functionality, and durability of the end documents and, consequently, the cost and use convenience. Here are document designs considerations:

The quality of carbon receipt paper significantly impacts the clarity and durability of the documents produced. Below are key quality considerations:

Safety considerations are also important, especially regarding the materials used in carbon receipt paper production. Here are key safety considerations:

A1: carbon receipt paper is used mainly for making copies of documents, whether from transactions such as invoices in retail environments, work orders in manufacturing and industrial settings, logistics and transportation, service industries such as hotels and repairs, or legal practices. Multi-part carbon receipt paper allows users to create several documents by working at the same time.

A2: Carbon receipt paper generally includes standard carbon receipt paper, multi-part carbon receipt paper, synthetic carbon receipt paper, and carbonless receipt paper. Standard carbon receipt paper is best for general use, and multi-part carbon receipt paper is for applications that require several copies. Synthetic carbon receipt paper provides enhanced durability, while carbonless receipt paper enables easy document duplication without carbon transfer.

A3: When buying carbon receipt paper, consider its weight (or GSM), ink density, and compatibility with existing systems. Quality paper is typically heavier, providing better clarity and reducing bleed-through. Ensure the paper is compatible with the system in use, both for thermal printers and POS.

A4: Yes, the size of carbon receipt paper matters significantly since various receipt printers and point-of-sale systems require particular widths and lengths to achieve carbon receipt paper size. A proper fit in terms of size maximizes the efficiency of devices; at the same time, the mismatch, where larger or smaller papers will lead in functionality problems regarding jamming and misprints.

A5: Numerous manufacturers of carbon receipt paper make efforts to diminish the impact environmentally by using sustainable virgin wood fibers in paper manufacturing. Also, the products are designed to be more efficient in energy usage throughout their life cycles.

A6: The main difference between carbon receipt paper and other types of receipt paper, such as thermal receipt paper, is the duplication process. Carbon receipt paper uses carbon ink and a transfer method to create copies, while other receipt papers (like thermal) use heat and chemical coatings for single copies.