Introduction to Bulk Cutter

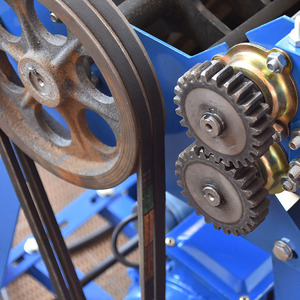

A bulk cutter is an essential tool designed for high-volume cutting tasks in various industries, ranging from manufacturing to construction. This heavy-duty apparatus is engineered to deliver precision, efficiency, and safety, making it ideal for businesses that rely on consistently accurate cuts. Whether you are dealing with textiles, metal sheets, or plastic components, a bulk cutter ensures that you get the job done swiftly and effectively, ultimately enhancing productivity and reducing waste.

Types of Bulk Cutters

Bulk cutters come in several types, each cater to specific applications and materials. Understanding the different kinds can help you choose the right one for your needs:

- Electric Bulk Cutters: These are powered by electricity, offering high-speed operations and suitable for thick materials.

- Pneumatic Bulk Cutters: Utilizing compressed air, these cutters are lightweight and fast, perfect for cutting softer materials.

- Manual Bulk Cutters: Often used for smaller operations, these cutters are operated by hand and are ideal for precision cuts on a smaller scale.

- Automated Bulk Cutters: Equipped with advanced technology, these cutters can automate the cutting process for large-scale production lines.

Applications of Bulk Cutters

The versatility of bulk cutters makes them beneficial across various industrial sectors:

- Textile Industry: Used for cutting fabric rolls, ensuring uniformity and precision.

- Metalworking: Essential for slicing metal sheets or rods with accuracy.

- Construction: Ideal for cutting insulation materials, plastics, and other construction elements.

- Food Industry: Employed in processing plants for slicing bulk food items quickly and efficiently.

Features and Advantages of Bulk Cutters

When investing in a bulk cutter, it's crucial to understand its key features and advantages:

- Speed: Bulk cutters provide faster cutting speeds compared to manual options, significantly improving efficiency.

- Precision: The precision offered by bulk cutters reduces material waste and enhances the final product quality.

- Versatility: Suitable for a wide range of materials including fabrics, plastics, and metals, making them adaptable to various tasks.

- Ergonomics: Many bulk cutters come with ergonomic designs to enhance user comfort and reduce fatigue during prolonged use.

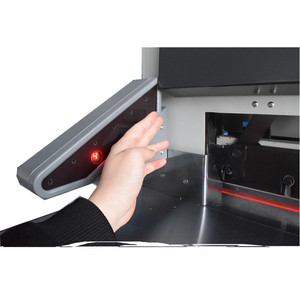

- Safety Features: Equipped with safety mechanisms that protect operators and reduce the risk of accidents.