(3254 products available)

The brackish water membrane is an integral part of seawater desalination plants that serve to filter out the salt particles and provide fresh water. There are several types of brackish water filtration membranes:

A nanofiltration (NF) membrane is a molecular sieve that selectively allows the transfer of water molecules while rejecting multivalent ions and organic compounds. Nanofiltration membranes are typically composed of thin-film composite materials with a porous sublayer, which includes a polysulfone or polyethersulfone polymer, that provide effective separation characteristics. The nanofiltration process involves the diffusion of water through the membrane's pores, where it is captured, leaving behind the rejected salts and contaminants. The concentration polarization phenomenon occurs when dissolved substances gather near the membrane surface, decreasing the osmotic pressure and boosting water permeation. Nanofiltration operates at lower pressures than reverse osmosis, making it suitable for water softening, dye removal, and treatment of wastewater with low organic matter content.

An ultrafiltration (UF) membrane is a water treatment barrier that separates suspended solids, bacteria, and larger molecules from water. Ultrafiltration membranes are made of polymeric materials like PVDF, Merofil, or Hydranautics, and they typically have tubular, hollow fiber, or flat sheet configurations. The ultrafiltration process relies on size exclusion, where particles larger than the membrane's pore size are retained, and water and smaller constituents pass through. Operating at low transmembrane pressures, ultrafiltration effectively removes river and lake water turbidity, pathogenic microorganisms, and larger organic matter, making it a crucial pre-treatment step for reverse osmosis in various water treatment applications.

A microfiltration (MF) membrane is a type of polymeric membrane that acts as a filtration barrier, removing particles, including bacteria and fine suspended solids, from water. Microfiltration membranes are available in various configurations such as hollow fiber, tubular, or flat sheet, and they are made from materials including polyvinylidene fluoride (PVDF), polypropylene (PP), and polysulfone (PSF). Microfiltration operates at low pressures, typically below one bar, by allowing water to pass through while retaining larger particles and microorganisms. Microfiltration is commonly used as a standalone treatment for potable water, pre-treatment for reverse osmosis systems, and in the treatment of wastewater, making it suitable for a wide variety of industrial and municipal applications.

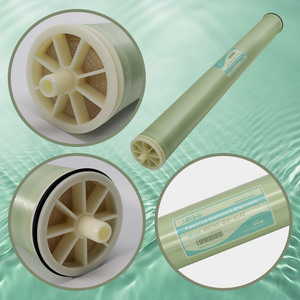

Brackish water reverse osmosis membrane elements are made to meet particular needs in terms of dimensions and permeate flow rate. The following specifications include brackish water RO membrane elements:

Length

Brackish water membranes come in a variety of element length sizes. The standard lengths, which influence how they fit into systems, are 2, 4, 8, and 40 inches.

Diameter

Brackish water RO membranes are constructed with either a 0.5-inch (thin film composite) or 2.5-inch diameter (spiral wound) configuration. The geometric configuration affects how tightly the membrane is packed and how efficiently it filters.

Flow Rate

Brackish water RO membranes have different flow rates depending on the size and pressure. The flow rate measures how much water goes through the membrane and is typically expressed in gallons per minute (GPM) or liters per hour (LPH).

Rejection Rate

Brackish water RO membranes are made with various rejection rates to remove contaminants like salts and minerals effectively. Higher rejection rates indicate better contaminant removal. The rejection rates are usually between 90% and 99%.

Proper maintenance can maximize the performance and lifespan of brackish water reverse osmosis membranes. Here are some helpful tips on maintaining the membranes:

Brackish water membranes have a large scope of application, which implies that they have many usage scenarios in the industry.

Desalination

Brackish water membranes are commonly used in desalination, which converts brackish or saltwater into freshwater. The process is essential in areas where freshwater resources are limited. By using brackish water membranes in the desalination process, people can obtain a sustainable supply of freshwater for municipal, industrial, or agricultural needs.

Water treatment

Brackish water membranes are also used in the water treatment process to remove pollutants, contaminants, or harmful substances from the effluent. Their use in water treatment can help improve the quality of the water, making it safe for human consumption.

Industrial processes

Brackish water membranes also have a role to play in the industrial processes. For example, they can be used to concentrate substances, recover solvents, or purify products in industries such as food and beverage, pharmaceuticals, chemicals, or mining. The membranes enable the efficient separation of specific components, helping to enhance productivity and process integrity.

Seawater intrusion

Seawater intrusion occurs when salt seawater enters freshwater aquifers, which can make the groundwater supply face a great deal of risk. Brackish water membranes, by extracting the salt ions in the contaminated groundwater, can protect the natural aquifer systems and can help restore the quality of the groundwater.

Aquaculture

In aquaculture, brackish water membranes are frequently used to adjust the salinity levels in fish farms or aquatic culture systems. The technology can create an optimal living environment for aquatic organisms, thus promoting their growth and productivity.

Desalination of industrial wastewater

Brackish water membranes also can be used for the desalination of industrial wastewater. They help recover valuable resources, such as water and salts, which can be reused within the production processes or safely discharged into the environment.

When selecting brackish water reverse osmosis membranes, the following factors need to be considered:

Feed Water Analysis:

To select the proper brackish water membrane, it is essential to analyze the characteristic factors of the feed water, such as total dissolved solids (TDS), turbidity, organic matter, and other specific contaminants. Different waters need to use different types of membranes to achieve the desired treatment effect.

Available Membrane Types:

Many brackish water membranes are available, including polyamide thin-film composite membranes, cellulose acetate membranes, and more. Each membrane has a specific separation performance and chemical stability, so they are suitable for different applications and user needs. Make sure the chosen membrane type can effectively remove the specific contaminants in the feed water.

Brackish Water Polyamide Thin-Film Composite Membrane: This membrane type has a high separation factor and is suitable for removing various dissolved solids, making it suitable for treating brackish water.

Brackish Water Cellulose Acetate Membrane: Although this membrane is gradually less widely used, it still applies to some specific situations. It has good removal efficiency for certain contaminants, but its performance may decline faster than polyamide thin-film composite membranes.

Membrane Module Configuration:

Membranes are usually provided in module forms. Users need to choose the proper module configuration, including the module size and quantity, according to their own water treatment system and processing demand. Ensure that the selected membrane module can integrate well with the user's equipment and meet their processing needs.

Operating Parameters:

Operating parameters include factors like pressure, flow rate, and temperature. Different membranes have specific operating parameter requirements. When selecting, ensure that the selected membrane can work efficiently and stably under the normal operating parameters of the user's water treatment system.

Equipment Compatibility:

When selecting membranes, users need to ensure that the membranes they choose are compatible with their brackish water treatment equipment. The membrane module needs to connect and work with other system components, such as pumps, pipes, and control devices.

Service Life and Replacement Cycle:

Users need to consider the service life and replacement cycle of the selected membrane. A longer service life and reasonable replacement cycle can help users reduce maintenance costs and operational interruptions.

Membrane Supplier:

Users need to choose a reliable membrane supplier. Consider the supplier's product quality, technical support, and after-sales service. Suppliers should provide comprehensive technical literature and installation, maintenance, and troubleshooting guidance.

Q1: How efficient are the brackish water membranes?

A1: Generally, the efficiency of reverse osmosis membranes can exceed 90%. Some high-performance RO membranes can even achieve up to 98% desalination.

Q2: What is the longevity of a brackish water membrane?

A2: The lifespan of brackish water membranes can vary depending on many factors, such as the water quality, operating conditions, and maintenance. However, many brackish water membranes can last 5-10 years or even longer under proper maintenance and care.

Q3: Can used brackish water membranes be recycled?

A3: At present, the mainstream recycling methods of used brackish water membranes are physical methods, such as incineration or landfill, which have a negative impact on the environment. Chinese brackish water membrane manufacturers are studying the recycling value of brackish water membranes chemically.

Q4: Will the brackish water membrane degrade the flavor of water?

A4: No, if a brackish water membrane functions properly and is free of pollutants, it can make water taste better by removing substances that cause bad taste, such as chlorine, chlorinated compounds, sodium, and dissolved minerals. However, if people become aware of the excellent brackish water membrane, they should examine the water treatment system and brackish water membrane to see if there are any problems.

Q5: Can people get rid of brackish water membranes in the home water treatment system?

A5: The brackish water membrane lacks fundamental brackish water desalination knowledge and the working principle. Therefore, it cannot be removed. Please consult the professional.