(73901 products available)

![[Gobricks]GDS-986 Building <strong>Block</strong>(No.32002)1 1/2 <strong>M</strong> CONNECTING BUSH - 3/4 Tie Length 11.7](http://s.alicdn.com/@sc04/kf/H455fcaf4a538479684ca753d8b0010317.jpg_300x300.jpg)

![[Gobricks]GDS-986 Building <strong>Block</strong>(No.32002)1 1/2 <strong>M</strong> CONNECTING BUSH - 3/4 Tie Length 11.7](http://s.alicdn.com/@sc04/kf/Ha1c40e765baa44e78e6a232de848efd1W.jpg_300x300.jpg)

![[Gobricks]GDS-986 Building <strong>Block</strong>(No.32002)1 1/2 <strong>M</strong> CONNECTING BUSH - 3/4 Tie Length 11.7](http://s.alicdn.com/@sc04/kf/H838ad425b1734f4b98cd792d3d66dea9y.jpg_300x300.jpg)

![[Gobricks]GDS-986 Building <strong>Block</strong>(No.32002)1 1/2 <strong>M</strong> CONNECTING BUSH - 3/4 Tie Length 11.7](http://s.alicdn.com/@sc04/kf/H2e25ea8fce364bdfb4f937d36f4b83c6t.jpg_300x300.jpg)

![[Gobricks]GDS-986 Building <strong>Block</strong>(No.32002)1 1/2 <strong>M</strong> CONNECTING BUSH - 3/4 Tie Length 11.7](http://s.alicdn.com/@sc04/kf/H3f8106f285234777847a66510eb751deA.jpg_300x300.jpg)

![[Gobricks]GDS-986 Building <strong>Block</strong>(No.32002)1 1/2 <strong>M</strong> CONNECTING BUSH - 3/4 Tie Length 11.7](http://s.alicdn.com/@sc04/kf/H874b1adadb5b4092a3935fd77a6b2e39Q.jpg_300x300.jpg)

The block m machine has different specifications and variations according to regional requirements and preferences. The below types are based on the working principle and method of making block m.

The specifications of a concrete block m are usually based on the kind of concrete block one wishes to produce. Concrete blocks are generally larger than regular brick that is 7.5 inches long, 3 inches high, and 4 inches thick. When manufacturing concrete blocks, one can use the following specifications.

The maintenance of a concrete block m requires regular cleaning and lubrication, periodic inspections and repairs, and routine maintenance and calibration. The first step in maintaining a block m is to keep the machine clean by using a pressure washer. The oiling of the moving parts of the block machine ensures that it runs smoothly and efficiently. Frequent checks of the machine for signs of wear and tear and areas needing repair will prolong the life of the block m. Any parts that need adjustment to improve the performance of the machine should be calibrated. Follow the manufacturer's instructions for all the maintenance procedures.

Interface:

The block M is commonly used in machine interfaces. It is placed at an angle so that the user can see the screen output clearly. This includes control panels in cars, aircraft, and other complex vehicles and devices.

Microphone:

A small block M is placed in some types of microphones.

In this application, it is used to pick up sound waves from the air. This includes sound pickup in public address systems, telephones, tape recorders, and other devices requiring sound pick-up or reproduction.

Connector:

In electronics, the block M connector joins two electronic components. It transfers power or data between the two devices.

Power transfer in personal computers, where power is delivered from the power supply unit (PSU) to components like the motherboard and graphics card, is one application. Another is data transfer in audio and video equipment.

Package:

In logistics and supply chain management, the block M packaging design is sometimes used in blocks to maximize warehouse storage. This is also true when using products with similar shapes. The packaging is designed to optimize space and prevent the product from being damaged.

Floor tile:

The block M is a 12''x12'' structural slab concrete floor tile. It can be utilized in industrial, commercial, and residential buildings. It is commonly used in public places that require flooring that is very strong, durable, slip-resistant, and easy to clean.

Fire extinguisher (FEM):

Block M fire extinguisher m fittings are manufactured from aluminum alloys. They are lightweight but still have incredible strength. The aluminum alloy will not rust. This means that the machine will be ready for use even in challenging situations and environments.

Material Selection:

When picking materials for block production, it's crucial to think about durability and cost-effectiveness. Many options are out there, but two popular choices are concrete and gypsum. Concrete is known for being tough and long-lasting, while lightweight concrete blocks can make transportation easier.

Customizable Molds:

For versatile block production, choose machine molds that can be adjusted. Customizable molds allow businesses to create blocks in various shapes and sizes to meet different construction demands. Customizable molds lead to block production that is more efficient, economical, and adaptable.

Block Machine Automation:

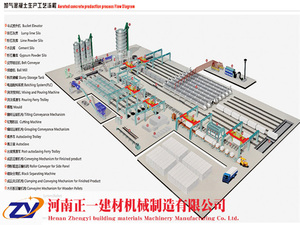

Consider the level of automation in the block machine when selecting it. Machines with higher automation can boost output and cut labor costs by simplifying the block-making procedure. Choose fully automated machines with simple control systems, semi-automated machines with controlled manual operation, or fully automatic machines with block production lines.

Production Capacity:

A vital factor when choosing a block-making machine is its output capacity. It indicates how many blocks the machine can produce in a specific time frame. Based on market demands and anticipated development goals, businesses should determine their required output. To fulfill production needs, select a block machine with the right capacity range.

Energy Efficiency:

Consider the energy efficiency of the block machine, which affects energy consumption and production costs. Select block machines with energy-saving technology and efficient motors to save electricity usage. Choose machines that have a variety of energy-saving modes to allow businesses to save energy during block production. Selecting machines with higher energy efficiency can considerably lower production expenses and support environmental sustainability.

Q1: Is the performance of the cement block machine good?

A1: The block machine performance is good. The production speed is rapid with average 50 seconds per block forming time. The machine pressure and vibration produce dense and high-strength blocks.

Q2: What is the productivity of block machines?

A2: The productivity depends on the machine. For example, a semi-automatic block machine produces approximately 1,000 to 2,000 blocks in an 8-hour shift. In contrast, fully automatic block machines may produce 3,000 to 5,000 blocks in an 8-hour shift.

Q3: Can block machines make different sizes of blocks?

A3: Yes, the block machines are versatile and can make various sizes and shapes of blocks by changing the molds.