(3585 products available)

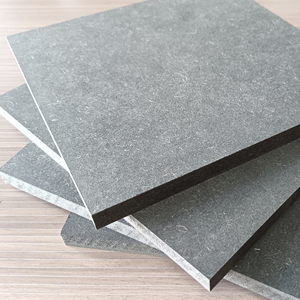

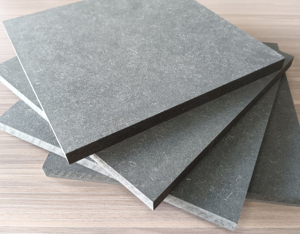

Black fiberboard, also known as fiberboard, is a type of engineered wood product made from wood fibers and adhesive resins. It comes in different densities and finishes, which makes it suitable for a wide range of applications. It is essential to know the types of black fiberboards to cater to specific needs.

High-Density Fiberboard (HDF)

HDF, also known as MDF (Medium Density Fiberboard), is the most popular black fiberboard. It is made by combining wood fibers, wax, and resin under high pressure and heat. The result is a smooth, dense board with a uniform appearance. MDF boards are popular because they are more affordable than other engineered wood options. They are widely used in the furniture and cabinetry industry.

MDF comes in different varieties, including water-resistant, lightweight, and general-purpose MDF.

High-Density Fiberboard (HDF)

HDF fiberboard has a density of 750-900 kg/m3. It is manufactured using a dry process that involves the use of adhesives such as urea-formaldehyde. The boards are compact and have a smooth, homogeneous surface. HDF boards are used in applications like flooring and sound insulation.

Hardboard (HDF)

Hardboard is a type of fiberboard made from wood fibers that are bonded together using heat and pressure without adding adhesive. It is made using the dry process.

It has a density of 900-1500 kg/m3. The board is very dense, flat, and rigid. It is mostly used for applications requiring high strength and rigidity, such as back panels in cabinets and furniture.

Low-Density Fiberboard (LFD)

LFD fiberboard is manufactured using a wet process. It has a lower fiber density, meaning it is lighter and less dense than LDF and HDF. It is not very rigid and has a rough surface. It is used mostly as acoustic ceiling tiles and insulation.

Specialized Fiberboard

This category includes several fiberboards like:

Acoustic fiberboard: Made specifically for sound absorption and noise control in commercial and residential spaces.

Imperial fiberboard: A type of low-density fiberboard used in building construction.

Fire-rated fiberboard: Engineered to meet specific fire safety standards and regulations. It provides enhanced fire resistance.

Water-resistant fiberboard: Treated during manufacturing with special additives to prevent water and moisture damage. It is ideal for high-humidity areas like bathrooms and kitchens.

Moisture-resilient:

Black fiberboard is made with waxy additives that make it moisture-resistant. This helps stop mold growth and prevents the board from warping when exposed to water.

Great strength:

Black fiberboards have excellent durability and strength. It can bear heavy loads without breaking or bending. This makes it suitable for applications like flooring and load-bearing walls.

Smooth and consistent surface:

It has a smooth surface without any bumps or irregularities. This makes it ideal for applications where a smooth surface is needed, like printing and painting.

Black fiberboards are simple to work with:

Black fiberboard is easy to cut, shape, and join together to make different things. It is great for DIY projects and professionals.

Versatility:

Black fiberboards can be used for many different things. It is used to make furniture, walls, and decorative items. It is used in many industries, like construction, automotive, and electronics.

Cost-effective:

Black fiberboards are cheaper than other building materials like wood and metal. This makes it a good option for projects with a limited budget.

Environmental benefits:

This board is usually made from recycled materials or by using less energy to process natural resources. This helps to conserve forests and reduce waste.

Adaptable thickness and size:

Black fiberboards come in different thicknesses and sizes. This allows designers and builders to choose the best board size for their needs.

Excellent appearance:

The black color of the fiberboard gives the finished product a sleek and modern look. It is used for visible surfaces where appearance matters.

Interior Applications

Black fiberboard is a go-to choice for architects and designers who want to create sophisticated and modern interior designs. Its smooth and sleek surface is perfect for when you want to achieve that desired minimalist look. Whether it's used for walls, ceilings, or furniture, black fiberboard blends seamlessly into contemporary spaces, adding a touch of elegance.

Sound Studios and Home Theaters

Black fiberboard is used in sound studios and home theaters because of its ability to absorb sound. Using it on walls and ceilings helps reduce echoes and creates a quiet environment for recording or watching movies.

Retail Displays

Black fiberboard is popular in the retail industry for making display fixtures and shelving units. Its neutral color and smooth surface draw attention to the products displayed, making them more appealing to customers.

Cabinetry and Built-in Storage

Black fiberboard is commonly used in the construction of cabinets, drawers, and built-in shelving units. Its durability and resistance to warping ensure that these storage solutions remain functional and attractive over time.

Backdrops and Stage Design

Fiberboard's black surface is used to create backdrops and set pieces in theaters and stage productions. Its light weight and ease of manipulation allow for quick changes and versatile designs, enhancing the visual impact of performances.

Artwork Presentation

Black fiberboard is used as a backing material for mounting and framing artwork. Its sturdy nature provides support and stability to paintings and prints, while the black surface adds a professional and polished look to the presentation.

Office Furniture

When it comes to office environments, black fiberboard is a popular choice for desks, cabinets, and conference room furniture. Its sleek appearance and ease of maintenance create a professional and organized atmosphere conducive to work.

Temporary Structures

Due to its low cost and lightweight characteristics, black fiberboard is often used in the construction of temporary partitions and displays at trade shows or events. Its adaptability and ease of assembly make it a practical option for creating a short-term space.

Choosing the right black fiberboard for a project involves considering several factors to ensure that the functionality, performance, and aesthetic requirements of the project are met. Here are some of the things that should be considered when choosing a black fiberboard:

Purpose and Application

The purpose of the black fiberboard should be the first consideration. Is it going to be used for furniture construction, cabinetry, wall paneling, or something else? Each application has unique requirements. For instance, MDF boards are ideal for furniture and cabinetry because of their smooth surface and ease of shaping. On the other hand, HDF boards are better suited for flooring applications due to their durability and wear resistance.

Moisture Resistance

Another factor to consider is the level of exposure to moisture the black fiberboard will be subject to. Some areas, like kitchens and bathrooms, require materials that can resist moisture. Such areas can otherwise lead to the growth of mold or cause the fiberboard to deform. In this case, the buyer should look for moisture-resistant black fiberboard, such as those manufactured using special wax additives during the MDF production process.

Durability and Strength

Fiberboard is available in different densities, which directly affects its strength and durability. Higher density boards offer better strength and durability than lower density boards and are therefore better suited for load-bearing applications. Examples include black hardboard and high-density MDF boards. On the other hand, lower density boards are more suitable for applications where weight is a concern.

Finishing Options

The finishing options available for the black fiberboard are another important consideration. To achieve the desired aesthetic look, one should select the board with the appropriate surface finish. For instance, smooth surface boards are more suitable for painting or varnishing, while textured surface boards can be used for decorative purposes. Additionally, some boards, like HDF, come in black card board options, which makes them more suitable for applications where a finished surface is visible.

Environmental Considerations

For buyers concerned with sustainability, it is important to select a black fiberboard made with environmentally friendly practices. Such boards are usually manufactured with recycled wood fibers and are more ecologically sustainable than standard options. Additionally, some manufacturers indicate the level of formaldehyde emissions, and those with low emissions are less harmful to the environment and human health.

Q: What is the difference between black fiberboard and MDF?

A: The main difference between black fiberboard and MDF is that the former uses a binder that makes it water-resistant, while the latter uses regular glue, which makes it water-resistant.

Q: What does black fiberboard feel like?

A: Black fiberboard feels smooth, flat, and dense. It also has a soft and hard feel when touched with the hand. The soft feel is from the smooth coating, while the hard feel is from the board's hardness.

Q: Can one nail through black fiberboard?

A: Yes, it is possible to nail through the board. However, it is advisable to use a nail that has a diameter of 2.5 mm. Using a larger nail can cause the board to split or crack.

Q: Does black fiberboard bend easily?

A: No, the board doesn't bend easily. It is stiff and stable due to its thickness, construction, and density. The fiberboard also has high strength and bending ability, which makes it a preferred choice for furniture manufacturers and architects.

Q: Is black fiberboard the same as plywood?

A: No, the two are not the same. Plywood is made from wood, while black fiberboard is made from wood. However, both are used for similar applications in construction and architectural design.

The web search volume for "black fiberboard" in the Construction & Real Estate category shows an average monthly search count of 90, with notable fluctuations over the past year. Despite a significant three-month decrease of 22%, the keyword experienced a substantial one-year increase of 40%. The data reveals a peak in May and June 2024 with 110 web searches, followed by a gradual decline back to the yearly average.

Analyzing the monthly search data for "black fiberboard," we notice a pattern of seasonal variation. The highest interest occurs during the late spring and early summer, with web search volumes dipping during the winter and stabilizing in the fall. This trend suggests that the demand for black fiberboard might be influenced by construction cycles and weather-related factors, which typically slow down during colder months.

The reasons behind these trends could be multifaceted. The peak during warmer months could correlate with a higher volume of construction activities, which generally increase during favorable weather conditions. The decline in web searches during colder months could be attributed to a slowdown in construction projects due to adverse weather conditions. Additionally, the overall yearly increase might indicate a growing interest in black fiberboard for specific applications within the construction industry, possibly driven by new building regulations or increased marketing efforts by manufacturers.