(936 products available)

These metallic parts have earned a reputation due to their durability. Many sewing machines in the industrial sector use metallic bobbins because they can endure high-speed sewing and heavy workloads. Their strength makes them compatible with tough threads like nylon and polyester, which are ideal for be products.These bobbins require minimal maintenance and do not warp or degrade as easily as some other materials.

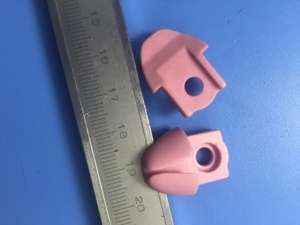

Plastic bobbins are lightweight and inexpensive, making them a popular choice for home sewing machines. While not as strong as metallic bobbins, plastic bobbins are sufficient for general sewing tasks. They are also less conductive, which can be an advantage when sewing with materials that might be affected by heat. Although plastic bobbins are less suitable for industrial use, their affordability and weight make them suitable for domestic use.

Some sewing machines, especially older models, utilize built-in bobbins. These integrated designs are intended specifically for certain machine models. This means that replacement options and compatible integrated bobbins might be hard to find when the sewing machine is used commercially. Nevertheless, incorporated bobbins manufacture in such a way that they help in space efficiency. They also streamline the sewing process by making sure the bobbin placement is correct.

These bobbins are designed to sit horizontally. They then drop into a compartment on top of the sewing machine. One of the benefits of a drop-in bobbin system is that it is very easy for users to load the thread. This makes it a popular option for beginner sewing machines. When looking for be productsconsider drop-in bobbins. They are good for basic sewing projects.

Front-loading bobbins are set into a case and then inserted from the front or side of the machine. While slightly more challenging to install than drop-in bobbins, they are a common feature in mid-range to high-end sewing machines. If one is using a machine with front-loading bobbins, it's important to become familiar with the correct threading and installation methods, as improper placement can lead to tension problems.

Typically, these are made from steel or aluminum. Often, they are coated with a layer of chrome of plastic for better longevity and to prevent rust. These bobbins are favored for their strength and can withstand high-speed sewing. In addition, they work well with heavy-duty threads like nylon or metallic. Because of their robust design, they are commonly used in industrial sewing machines.

Plastic bobbins are in most cases made from injection-molded plastic. This is because they are lightweight and inexpensive. They save on costs. While not as durable as metallic bobbins, plastic bobbins are suitable for home sewing. Also, they are often used for lighter fabrics and basic sewing projects. In addition, the lack of metal means that plastic bobbins are less likely to damage delicate fabrics if a part breaks.

Ceramic bobbins have recently become popular due to their strength and the lightweight nature they come in. Their robustness and smooth surface ensure even thread distribution. This helps to avoid tangling and threads becoming uneven. Ceramic is often preferred for high-performance sewing machines. In addition, they are beneficial when working with high-temperature threads or during extended sewing sessions since they do not conduct heat.

Wooden bobbins have historical importance. This is because people have used them before modern materials became popular. Even though the strength has reduced, they are still in use today, mainly for vintage sewing machines or specialized textile machinery. The craftsmanship involved in making wooden bobbins gives them a unique quality. This quality helps to minimize thread tension when sewing. Therefore, this makes them good for handlooms or sewing machines that have a low tension setting.

Manufacturers make elastic bobbins from different kinds of elastic materials. This includes threads, cords, or synthetic elastics. One of their benefits is that they come with adjustable tension. This makes them ideal for gathering fabrics or creating fitted features such as darts and elastic casings. They are indispensable for clothing manufacturers who make stretch garments such as sportswear or lingerie.

Thread tension is a key factor when making textiles. Bobbins help to regulate it. Even thread distribution ensures the quality of the fabric. This is one of the reasons why bobbins are important for manufacturing clothes.Mostly, manufacturers use this equipment for mass production. Therefore, the precision and consistency that bobbins bring are important for efficiency and quality control.

Bobbins are crucial in this industry where large pieces of fabric are sewn together. This includes sewing chair covers, curtains, and other upholstery items. People mainly use industrial sewing machines to handle the heavy materials used. These machines, which have bobbins, ensure that the stitching is strong and durable. Durable stitching ensures that the upholstery can withstand wear and tear.

Whether it be vehicles or any other means of transport, bobbins are found in sewing parts like seats, airbags, and interiors. The stitching is very important for safety and aesthetics. Again, industrial sewing machines with bobbins are used to ensure that the stitching used in these crucial applications is up to standard. For manufacturers who make car seats, consider investing in quality bobbins. These are key to making the best seat covers.

Labeling machines, a key element in the textile industry, use bobbins to attach tags, labels, or decorative elements to garments. This ensures that every piece has the necessary branding or care instructions. Bobbin threads are commonly used in embroidery machines to add logos, designs, or patterns on apparel. Companies use this to help with their branding. Therefore, bobbins play an important part in quality control. They ensure that the labels are attached properly.

Apart from sewing, bobbins are also used in winding and rewinding equipment. For example, they are in wire or cable manufacturing. In this realm, bobbins serve as a core around which materials are wound. This means that bobbins are instrumental in managing and storing linear materials. Essentially, these components provide support and facilitate the organized handling of various materials.

Choosing the correct bobbin for a project is very important. When making clothing, one has to consider the material of the fabric to be sewn. For delicate materials like silk, lightweight plastic bobbins are ideal. On the contrary, robust fabric like denim requires a more durable metallic bobbin. Therefore, the fabric dictates the type of bobbin to use.

The project requirements also matter. For basic clothing repairs or simple stitching jobs, standard plastic bobbins are sufficient. However, more demanding tasks that involve heavy-duty sewing or complex patterns will require strong, metallic bobbins. Take time to consider the sewing thread. Polyester and nylon threads are strong and flexible. A plastic or ceramic bobbin is suitable for these kinds of threads. Using the right kind of bobbin ensures the project comes out great.

Use only quality bobbins. Quality bobbins reduce the risk of thread tangling and breaking during the sewing process. It reduces downtime. Choose a machine's make and model when choosing a bobbin. It's really important to use the right size bobbin. Using the wrong bobbin size can cause poor sewing machine performance and even damage the machine, and the finished item will not come out looking nice. It's very important to stock up on new bobbins from the same manufacturer as the original one. Manufacturing companies may change their designs and materials over time. If people add new bobbins that are changing in size or design, they will tangle, and the sewing machine will not operate as it should.

A1: Bobbins can be found in sewing machines. Also, they are in computer-controlled sewing machines that make be embroidery work easier.

A2: Normally, bobbins are wound with the lower thread that is used when making stitches. They help mainly in controlling thread tension.

A3: Plastic bobbins are lighter and suitable for home sewing. Metallic ones are more robust. They work well for industrial or heavy-duty sewing projects.

A4: Pre-wound bobbins come ready with thread. They are convenient for projects where consistent tension and thread amount are key. They save time because users don't have to wind their own.

A5: Most modern sewing machines have a bobbin case that accommodates a specific size of bobbin, usually either class 15 or M style. To avoid damage, it's essential to verify that the selected bobbin matches the machine's requirements.