(1809 products available)

Market Overview: The global computer numerical control (CNC) market, which includes bcamcnc CNC routers, reached a size of approximately $85.9 billion in 2023 and is projected to grow to $139.0 billion by 2032, marking a compound annual growth rate (CAGR) of 5.5% during the period from 2023 to 2032, according to Research and Markets. This growth is primarily driven by the increasing adoption of advanced CNC machines in various sectors, including additive manufacturing and small-scale industries. The integration of innovative technologies, such as 4, 5, and 6-axis machining, enhances the precision and efficiency of CNC routers, making them essential tools in modern manufacturing environments. Additionally, the Asia-Pacific region has emerged as the largest market for CNC technology, fueled by significant investments in manufacturing and technological advancements.

Industry Insights: The bcamcnc CNC router segment benefits from a variety of market drivers, including the rising demand for customization and prototyping, especially in the automotive and aerospace industries. As manufacturers seek to improve accuracy and reduce operational costs, the adoption of CNC technology is becoming increasingly prevalent. However, challenges such as high maintenance costs and the technical complexity of CNC systems may deter some end-users. Despite these hurdles, opportunities abound with advancements in machine learning and artificial intelligence, which are set to transform CNC operations. Overall, the competitive landscape is fragmented, with numerous players vying for market share, which indicates a dynamic and evolving marketplace for bcamcnc CNC routers and related machinery.

BcamCNC routers come in different types to suit particular applications and needs. Below are some of the most popular ones:

Here are some specifications and maintenance tips for a BcamCNC 3D CNC router:

Worktable Size:

BcamCNC worktables sizes differ depending on the model. For example, the worktable size for the 3D 1310 model is 1300 x 2500 mm.

Motor:

The motor driving the router bit differs from the one that drives the axis. The motor that drives the axis is responsible for the movement of the entire router, while the spindle motor drives the router bit that cuts the material. BcamCNC routers have different motor types, including twin drive and leadshine motors.

Router Bit:

A BcamCNC router bit can have two types of shafts: straight and tapered. It can be of multiple sizes and have diverse functions, from fine engraving to heavy milling. Generally, a router bit has an open shaft that is inserted and tightened into the router head.

Supported File Types:

A BCamCNC router programming file type is a guideline for a specific CNC machine, detailing instructions concerning cutting and machining various materials. The file type may include features like routing, milling, engraving, or cutting. The instruction might involve the order of operations, the types of tools to be used, the materials to be worked on, and the precision required. Some BCamCNC file types are .CNC, .DST, .DXF, and .TPR.

Tips to maintain BcamCNC 3D CNC router:

One of the main benefits of a Bcamcnc CNC router is its versatility. As a result, the machine can be used in many industries and applications, some of which include the following.

When selecting the proper BCamCNC CNC router machine for an individual's or an enterprise's needs, several features and characteristics should be taken into consideration:

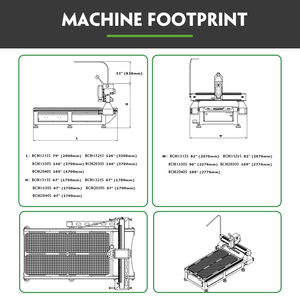

Machine Size and Workspace

Generally, CNC routers come in different sizes, from desktop to large-scale models. Users should first consider the size of the objects they plan to cut and the available workspace. For this, they might think about their shop floor space and whether portability is a requirement.

Supported Materials

Generally, different CNC router machines are designed to work with specific types of materials. An example is the ATC CNC router, which is specially designed to work with hardwood. As such, one should choose a model appropriate for the materials they will be using, as this will ensure optimal performance and results.

Cutting Depth and Speeds

When choosing a BCamCNC CNC router machine, one might need to consider the cutting depth and the speed of the router. This will impact how well the machine suits a user's application. Generally, if one's project involves cutting through thick materials or requiring high feed rates, selecting a router with greater cutting depths and faster speeds is key.

Spindle Power and Torque

Generally, spindle power and torque play an important role in determining how well the router will cut through different types of materials. One might need to choose a router with adequate power and torque to handle the thickness and hardness of the materials to be used.

Software Compatibility

Generally, the CNC router machine selected will determine how easy and efficient the routing projects will be. Before choosing a CNC router machine, one should look at the machine software to ensure that it is compatible with the preferred design software. This could also mean that the machine will be user-friendly and straightforward.

Q1: How deep can a CNC router cut?

A1: A CNC router generally cuts to a material's thickness or depth. When routing a material, one must consider the aspect cut depth or the maximum vertical depth of a feature that a CNC router can achieve. The cut depth also depends on factors like the bit, its dimensions, material density, and even the CNC machine's power. Typically, the aspect cut depths range from 3 to 10 mm.

Q2: Can one use any software for a CNC router?

A2: Generally, CAD/CAM software is specifically designed to create projects for CNC machines. This means they will include the tool paths, instructions, and cutting sequences necessary for the CNC machine to read and follow them accurately. However, one can also use other types of software, such as 3D modeling or design software, that are not specifically CNC router software.

Q3: How fast does a CNC router machine go?

A3: The speed of a CNC router machine is determined using its feed rate, usually measured in inches per minute (IPM) or millimeters per minute (mm/min). Factors such as material, project type, router power, and bit type will determine how fast the CNC machine will cut. Generally, CNC routers have a maximum spindle speed of around 24000 to 30000rpm.