(13 products available)

The automatic PCB deburring machine comes in many models and types, each built with a specific mechanism to remove burrs effectively from PCBs. Some of the most common ones include the laser machines, the drill-type deburring machines, the rotary tools, and many more.

Automatic laser PCB deburring machine:

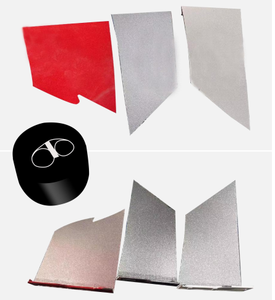

These types of machines use laser cutting technology to eliminate burrs and achieve a clean edge. They are used mostly on thicker materials that are difficult to cut or deburr using standard methods. The machine works by directing a high-powered laser beam onto the burr area of the PCB, vaporizing it precisely and leaving a clean edge behind. One of the greatest advantages of these laser deburring machines is the fact that they give pristine precision and control. Operators can easily target specific areas on the PCB that have burrs, and the intensity of the laser is also adjustable. This means that they get to customize the level of deburring for different kinds of materials.

)>Also, these machines can deburr multiple layers of PCBs at once. They are very useful in automotive industries, medical fields, and even aerospace applications. One important thing to note is that a laser deburring machine requires a certain level of expertise and knowledge for proper use and safety, so operators have to be well-trained.

Automatic drill-type PCB deburring machine:

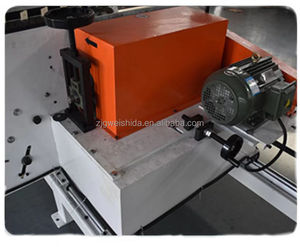

This machine uses rotary tooling to remove the burrs. It is commonly powered by air, electric, or even battery power. They can either be handheld or automated, depending on the exact application. The drill bit is the main component of this machine, and it works by grinding and cutting the burrs away. It reaches into tight spaces and corners of the PCB that are difficult to access with manual tools.

One of the main advantages of the drill bit deburring automatic machine is that they are very easy to use. Even a beginner can pick it up and use it without any knowledge or training. Also, they are normally very affordable compared to other machines. The drill bit deburring machine is ideal for use in applications that involve thin materials.

Rotary deburring tool:

Also known as the rotary burr remover/remover of PCB burrs, this tool is often used as a manual or power tool. It effectively removes burrs from the edges of holes, internal areas, and cavity features on circuit boards. The rotary deburring machine works using a rotating bit that smooths rough areas and eliminates embedded material. This happens without applying too much pressure that may damage critical surface features.

The rotary machine offers a quick and easy method for deburring PCBs. It is also very effective and efficient in the removal of burrs. It is a great addition to any workshop where circuit boards are processed frequently. However, operators may need some level of skill and experience to use the device properly and safely.

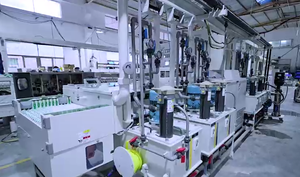

Automatic PCB deburring machines are versatile tools used in several industries to aid in the production and assembly of electronic devices. Here are some of the most common use cases of automatic PCB deburring machines:

Mobile Phone Manufacturers

Mobile phone manufacturers use automatic PCB deburring machines to remove burrs from mobile phone circuit boards. An automatic PCB deburring machine ensures the circuit boards are prepared accurately and swiftly for the subsequent stages of assembling the mobile phone.

Computers and Consumer Electronics

Computers, Television sets, DVD players and other consumer electronic devices are accompanied by complex circuit boards. The boards often have burrs that hinder optimal board performance. Therefore, manufacturers of these devices employ automatic PCB deburring machines to get rid of the minute irregularities of the edges of the circuit boards, hence enhancing a perfect fit and the smooth function of connections.

Automotive Industry

In the automotive industry, circuit boards are commonly used for sensors, control units, and onboard entertainment systems. Therefore, the automotive manufacturer employs an automatic PCB deburring machine to quickly and accurately remove the burrs from these irregularly shaped circuit board edges, making the electrical connections solid and dependable.

Medical Device Manufacturing

Medical device manufacturing requires precision. As such, medical device manufacturers use automatic PCB deburring machines to ensure that circuit boards of medical devices such as diagnostic equipment, monitoring devices, and therapeutic devices have been accurately and precisely prepared for the assembly of sensitive and essential medical equipment.

Industrial Automation

In the industrial automation sector, automatic PCB deburring machines are used in the manufacturing of programmable logic controllers (PLCs), sensor boards, and control modules. The machines ensure precise electrical connections and streamlined assembly.

Contract Manufacturing

Contract manufacturers deal with a wide variety of customer specifications and projects. They employ the automatic PCB deburring machines for quick and accurate customization of the circuit boards for different customer specifications and project needs.

When looking for an automatic PCB beveling machine, buyers should consider several factors. For instance, they will need to determine the type of burrs the machine supports. Some automatic deburring machines only work with specific types of PCB edges. Also, buyers should consider the machine's production capacity. They should get a machine whose capacity matches their current needs. If they are planning to scale up in the future, they can get a machine that is currently meeting their needs and has the potential to scale up in the future.

The quality of the finished PCB is very important. Buyers should look for machines that provide a smooth edge finish without compromising the board integrity. The tool paths an automatic PCB deburring machine has can affect the quality of the finish. Some machines have multiple tool paths that optimize the routing process for different board types. Buyers may look for machines with additional paths.

The cost of the machine is an important consideration. Buyers should get machines that fit their overall budget. However, buyers shouldn’t compromise on quality just to save a few extra dollars. The machine should be able to easily integrate into the existing production line. It should also work seamlessly with the loading and unloading systems of other pieces of equipment. Deburring machines that can easily integrate will minimize redundancy and streamline the entire production process.

Whenever unsure about a feature, buyers should first consult with industry experts. Several features of an automatic PCB deburring machine can be complex. A helpful expert can explain some of the features and specs of the machine. In addition, they can provide guidance on selecting a machine that will meet current needs. Buyers can also benefit from reading reviews from previous users. They should mainly look for reviews in reputable sources. They should take notes on the strengths and weaknesses of several machines. Using reviews as a buying guide can help buyers select a reliable, effective, and efficient machine.

Q1: What is the difference between a manual and an automatic PCB deburring machine?

A1: The primary difference between manual and automatic PCB deburring machines is how operators handle the devices during the process. While a manual PCB deburring machine requires a lot of direct operator intervention for the task, observing the machine and using their hands to move the board around, an automatic one can do this automatically.

Q2: How safe are automatic PCB deburring machines?

A2: The automatic PCB deburring machine is very safe to operate, especially when taking extra precautionary measures. Users don'humiliation't have to worry about physically exerting themselves or getting injured on sharp edges coming off the board.

Q3: Can users modify an automatic deburring machine?

A3: Yes, some machines are capable of modifications, and it's possible to change them depending on the user's particular needs and preferences.

Q4: What are some features of state-of-the-art automatic PCB deburring machines?

A4: Look for features like dust extraction, dual workstations, and efficiency ratios of up to 99%.