Introduction to Automatic Molded FRP Grating Machine

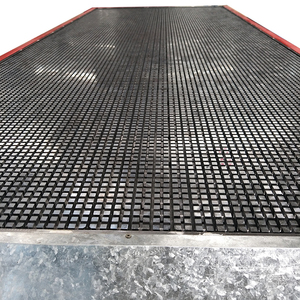

The automatic molded FRP grating machine represents a leap forward in the manufacturing processes of fiber-reinforced plastic (FRP) grating. This innovative machinery allows industries to produce high-quality, robust grating solutions that offer excellent corrosion resistance and mechanical strength. Ideal for various applications ranging from construction to wastewater treatment, these machines improve production efficiency and enhance product consistency. With advanced technology and automation, manufacturers can ensure precision in every grating panel created.

Types of Automatic Molded FRP Grating Machines

Automatic molded FRP grating machines come in various types, each tailored for specific needs in the production process. Here are the main categories:

- Standard Continuous Production Machines: Designed for mass production, these machines maintain high throughput and uniform quality.

- Batch Production Machines: Ideal for smaller operations, these machines allow for flexibility in manufacturing different sizes and grades of grating.

- Customized Airflow Technology Machines: These machines feature enhanced ventilation systems, providing complete control over the curing process for optimal strength.

- Portable Grating Machines: Compact and versatile, these machines are perfect for on-site operations where mobility is essential.

Applications of Automatic Molded FRP Grating Machines

The automatic molded FRP grating machine finds extensive applications across diverse industries due to its versatility and effectiveness:

- Construction: Utilized for flooring, walkways, and access covers that require lightweight yet strong materials.

- Wastewater Treatment: Employed in plants where corrosion resistance is crucial, ensuring longevity and reducing maintenance costs.

- Marine Environments: Perfect for applications in coastal areas thanks to its resistance to saltwater and harsh weather conditions.

- Chemical Processing: Reduces the risk of corrosion and other chemical damage, essential for processing plants handling aggressive substances.

Features and Advantages of Automatic Molded FRP Grating Machines

The automatic molded FRP grating machine is equipped with numerous features that streamline production while offering outstanding value:

- Advanced Automation: Reduces manual intervention, increases speed, and enhances safety in the production line.

- High Precision Control: Ensures consistent product quality through automated measurement and control systems.

- Diverse Material Compatibility: Can work with various types of fibers and resins, allowing for customization based on specific requirements.

- Environmentally Friendly Production: Minimizes waste and reduces the carbon footprint by optimizing material usage and energy consumption.

- Cost-Effectiveness: Decreases labor costs and increases production capacity, providing a high return on investment.