(86676 products available)

An automatic counting machine encompasses a machine with features and functions that ensure accurate counting, confirming, and verifying large volumes of products. The following are some of the types of counting machines:

Automatic Digital Counting Scale:

This machine combines an automatic counting mechanism with a digital scale to provide precise count and measurement simultaneously. The device counts the number of individual parts or items placed on the scale and records the weight of the items. It also allows users to enter a unit weight for faster counting of large quantities. Once the unit weight is recorded, the machine will calculate the number of items based on the total weight.

Counter-Based Automatic Counting Machine:

It is a type of counting machine that uses an automatic counter for tallying the number of items. The counter increments its tally every time an item passes through a sensor or trigger mechanism. This type of counting machine is mostly found in manufacturers' assembly lines, warehouses, and inventory management systems.

Optical Automatic Counting Machine:

This machine uses optical recognition systems, such as cameras and lasers, to automatically count items. Without altering their speed or position, these devices can read the number of objects and recognize their form, size, and orientation. Optical-based counting machines are often utilized in situations that require a high level of precision and rapid counting rates, like sorting lines, quality control, and surveillance.

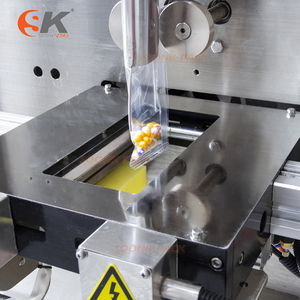

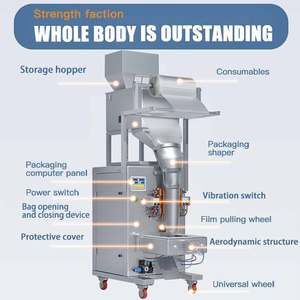

Pneumatic Automatic Counting Machine:

This device uses pneumatic systems to count items. It uses air pressure and flow to identify and tally objects as they move through the machine. Such counting devices are commonly used in packaging industries where the counted objects are small and lightweight items like pills, screws, and candies.

The specifications of an automatic counting machine may vary depending on the type and model. Here are some general specs to expect:

Counting Range

The counting machine can count items within a specific range. For instance, it can start counting from zero to five thousand. However, some might have upper limits like zero to ten thousand, depending on the functionality of the machine.

Accuracy

Generally, automatic counting machines are constructed to provide precise counts of items such as event participants, clicks or listens on digital platforms, and the number of people in a given area. Nevertheless, each machine model may have its own level of accuracy, with some being exceptionally precise and others slightly less so.

Input/Output mechanism

Some counting machines have keys, similar to a calculator, where users can input numbers and count. Others use an advanced touchscreen that allows a higher level of interaction to input numbers. Furthermore, some models can connect to external devices like sensors and cameras to output data to other devices.

Display

An automatic counting machine has a display that shows numbers counted. The display may be analog or digital, with different types of numbers, such as decimal counting, binary, or hexadecimal.

An automatic counting machine requires maintenance from time to time so that it can function properly and serve its purpose. Here are some maintenance tips for a counting machine:

The counting machine has various applications in different industries. One of its primary uses is to assist banks, credit unions, and financial institutions in managing their cash flow. The machine can be used to count large volumes of notes in a matter of seconds. It also minimizes the risk of human error by accurately reporting the number of notes.

With a sporting facility or event organizer, an automatic ticket counting machine can be used to track the number of tickets sold or attendees to an event.

Retail outlets can use coin counting machines to count coins from sales registers at the end of the day. The machine can also be used to track coin distribution in vending machines and kiosks.

Libraries use an automatic book counting system to track the number of books checked in and out each day. This helps the management to know the accurate figure without manually counting the books.

Donor-funded organizations can use donation counting machines to accurately track and record the number of individual donations that have been made during a fundraising campaign.

Manufacturing facilities with assembly lines can use piece counting machines to count the number of products at various production stages. The counting machine can help to maintain product quality and efficiency during the production process.

Specialized vs. General-Purpose Counters:

Consider whether the business needs a machine designed for specific items or one suitable for various items. Specialized counters may offer advanced features for particular products, while general-purpose counters have flexibility and adaptability.

Integration with Current Practices:

Consider how well the counting machine will mesh with current ways of doing things. Choose an automatic counting machine that works well with current equipment and software. This makes it easier to set up, reducing any disruptions to productivity.

Usability and User-Friendly Interface:

When choosing an automatic counting machine, consider its usability. Please take note of how simple it is to operate, with software that is user-friendly and features that can be quickly understood. Choose a machine that is easy to use so that training time and costs go down.

Capacity and Speed:

Select a counting machine with the proper capacity and speed to meet processing requirements. It ensures the machine can handle the expected counting volume and deliver the desired counting speed for operational efficiency.

Durability and Maintenance Considerations:

Choose an automatic counting machine built to last with good parts. Find machines that can withstand heavy use without breaking down often. Also, consider those that are easy to maintain, so they stay in good condition for a long time with minimal effort.

Data Tracking and Reporting Capabilities:

Some counting machines can track data and provide reports. If this is vital, choose a machine with data tracking and reporting features. It enables better monitoring and analysis of counting activities.

Q1: Which industries use a piece automatic counting machine?

A1: There are many industries that may use an automatic counting machine during different stages of production. They include the food and beverage sector, where they're used to count bottle caps, nuts, and other small processed foods. In the pharmaceutical industry, these machines ensure accurate counting and filling of tablets, capsules, and pills. The packaging industry also employs automating counting machines to ensure the right counts of labels, boxes, and other packaged products.

Q2: What are the benefits of using an automatic counting machine?

A2: An automatic counting machine offers various advantages to businesses, including increased speed and efficiency, precise and accurate counting, reduced labor costs and greater safety.

Q3: Can an automatic counting machine count irregularly shaped objects?

A3: Generally, an automatic counting machine can count irregularly shaped objects as long as the items can be detected and separated. However, the accuracy and efficiency of counting irregularly shaped objects may differ compared to counting spherical or uniform-shaped objects.