(2713 products available)

Argon gas valves are critical components in various industrial applications where inert gas control is paramount. These valves are designed to regulate and control the flow of argon gas, ensuring a stable and consistent supply when needed. From welding to laboratory research, the role of an argon gas valve is indispensable for precision and safety in operations.

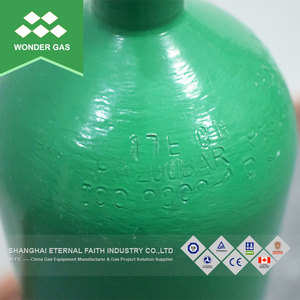

The market offers a diverse range of argon valves, each tailored for specific systems and requirements. An argon cylinder valve is commonly used in welding applications, providing a secure connection to the argon gas source. For those who require a more complex setup, an argon solenoid valve offers electronic control, allowing for automated gas flow regulation. The argon tank valve is another variant, typically found on larger storage containers, ensuring high-volume flow control with ease. For operations that require simultaneous control of multiple gas lines, an argon y valve or an inert gas y valve argon western 411 can be employed to manage dual gas paths efficiently.

Argon valves are not limited to a single application but are versatile in their use across various industries. The argon bottle valve plays a crucial role in the beverage industry, preserving the quality of wine by preventing oxidation. In the realm of metal fabrication, an argon gas valve ensures a protective atmosphere, crucial for high-quality welds free from contamination. Features of these valves include robust construction to withstand high pressures, precision control for accurate gas flow, and compatibility with various connection standards like the primeweld argon 125cf dot 3aa usa cga 580 valve.

Constructed from materials that can withstand the inert nature and pressure of argon gas, argon gas valves are typically made from brass, stainless steel, or other alloys that offer durability and corrosion resistance. The advantages of using a reliable argon gas cylinder valve include enhanced safety due to leak-proof designs, extended equipment lifespan thanks to high-quality materials, and improved operation efficiency through precise gas flow regulation.

Choosing the correct argon gas valve is crucial for any operation. Factors to consider include the valve's compatibility with the gas cylinder or tank, the required flow rate, and the specific application it will be used for. It is essential to select a valve that meets the industry standards and is appropriate for the gas pressure and volume requirements of the task at hand.

In conclusion, argon gas valves are a key component in managing the safe and efficient use of argon gas in various industrial applications. With a range of types and features available, it is important to select the right valve for your specific needs, ensuring the integrity and success of your operations.