(30 products available)

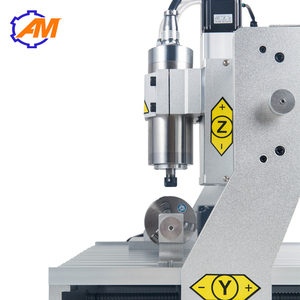

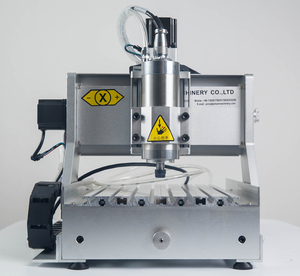

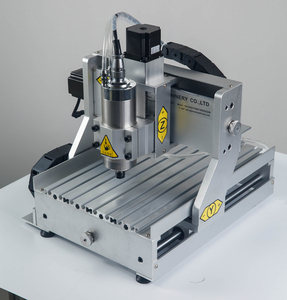

Aman offers several types of 4-axis CNC machines. The table below highlights some of them:

It's important for users and owners to understand the specifications and maintenance needs of the Aman CNC 4 Axis machine so they can be sure it works well and for as long as possible.

An average CNC 4 Axis machine has the following specifications:

To ensure optimum performance, the 4 Axis CNC machine must be maintained regularly and properly. Some timely and routine maintenance practices are:

The ability of the AMAN 4-axis CNC machine to work with various materials makes it a go-to machine in different industry sectors.

Woodworking Industry

A 4-axis CNC engraver is an important tool in the woodworking industry. Carpenters use it to engraving complex designs on wooden doors, furniture pieces, wall panels, and more. This machine boosts the creativity of woodworkers and allows them to add personalized touches to their work with ease.

Sign Making and Advertising

CNC 4 machines are widely used by sign makers and companies in the advertising industry. They use the machine to create 3D signs, sculptures, and promotional displays with great precision. The machine works fast, producing quality signage that meets clients' requirements.

Industrial Sector

The CNC 4-axis machine is invaluable in the industrial sector. It is used to make complex parts, including Turbine Blades, Gear Casing, Aircraft Ailerons, Valve Bodies, Propeller Hubs, Pump Casings, and more. These components are often used in transportation, power generation, petrochemical, maritime, and many other industries.

Jewelry Making

Jewelers use the CNC 4 axis to create intricate jewelry pieces with fancy patterns. These include rings, bracelets, earrings, and pendants. Its ability to precision cut and engrave valuable metals like gold, silver, and platinum makes it an ideal machine for this kind of work. The 4-axis CNC machine helps jewelers boost productivity and reduce manual labor.

Architectural Projects

The architectural industry makes good use of the 4th axis CNC machine. It creates large-scale architectural models and sculptures. The machine helps architects visualize their concepts and designs, which also helps to win client approval.

Automotive Industry

Automotive manufacturers use the 4th axis CNC machine to make car parts with great accuracy and reduce manufacturing time. Some of the components include panel cutouts, wheel rims, brackets, and engine covers. The CNC machine enhances the performance of vehicles by the quality of the parts it helps to produce.

Consider the following critical factors when choosing a 4-axis CNC machine that meets specific carving project needs:

Carving Requirements Analysis:

Determine the specific materials to be carved, their dimensions, and shapes, as well as the carving precision and intricacy required. This lays the foundation for selecting a suitable 4-axis CNC machine.

Machine Size Matching:

Choose a machine whose working area matches the dimensions of the objects to be carved to avoid size-related constraints during the carving process.

Spindle Power Selection:

Consider the material and carving speed needs to select a spindle with adequate power. This ensures the CNC machine can achieve the required carving depth and speed.

Control System Compatibility:

Ensure that the 4-axis CNC machine's control system is compatible with the design and production needs. Consider factors like ease of use, control accuracy, and support for file types.

Tool Selection and Management:

Choose a machine that supports the required tools and has an effective tool management system. This ensures the machine can use the tools needed for the job and manage them efficiently.

Integration of Supporting Facilities:

Apart from the CNC machine itself, consider other supporting facilities like dust collection, cooling systems, and tool changers. Proper integration of these facilities enhances the machine's overall performance and efficiency.

Q1: What are the advantages of a 4-axis CNC machine?

A1: The enhanced capabilities of 4-axis CNC machines over 3-axis models constitute one important benefit. Ama 4-axis CNC machines can execute more complex jobs and produce higher-quality products by adding an extra rotational axis. The longer cylindrical objects and ones with difficult forms are also within their machining capability. Another advantage is that workpieces can be cut from any direction, eliminating the need for multiple setups and reducing machining time.

Q2: What are the differences between 3-axis, 4-axis, and 5-axis CNC machines?

A2: In CNC machines with only straight motion, three axes are involved: left to right on a stationary plane (X), forward and backward along a perpendicular direction (Y), and up and down (Z). The addition of rotation about the X axis in 4-axis machines makes it possible to mill workpieces that are more complicated and to a higher standard. 5-axis CNC machines, which have two rotational axes (the A and B axes), offer even greater freedom of movement and are generally used for more industrial-scale requirements.

Q3: What are the commonly used CNC 4-axis machines?

A3: CNC laser engraving machines are frequently utilized for marking, writing, and etching on different materials, including metal, plastic, and wood. CNC milling machines are commonly used to explain the above definition; CNC rotary machining centers are designed to have a work holder that can spin and thus present different work faces to a stationary cutter.