(34546 products available)

Aluminum core manufacturers are companies that produce and supply aluminum cores for various applications. An aluminum core is an aluminum metal center that provides strength and stability for different products. It is used in several applications, including:

Different manufacturers produce aluminum cores for specific applications. For instance:

The aluminum core manufacturers focus on the following functions and features when producing their materials:

Conductivity

The aluminum core is known for its excellent electrical and thermal conductivity. This allows for even heat distribution during cooking, reducing hot spots and making food more efficient and evenly cooked.

Lightweight

Aluminum is a lightweight material. This makes cookware with aluminum cores easier to handle and maneuver than heavier options. This core's lightness makes it a popular choice for adding to lightweight cookware.

Durability

The aluminum core provides strength and durability to the cookware. It is resistant to warping and bending, ensuring that the cookware maintains its shape over time and with regular use.

Heat distribution

The aluminum core ensures that heat is distributed evenly across the cookware surface. This helps to cook food evenly and prevents areas where food may burn or stick due to excessive heat.

Non-reactive surface

The aluminum core is often coated with materials such as stainless steel or hard-anodized aluminum. This creates a non-reactive cooking surface, which is important when cooking acidic foods such as tomatoes or vinegar-based sauces. A non-reactive surface also makes cookware easier to clean and maintain.

Compatibility with different heat sources

Cookware with aluminum cores is designed to work with various heat sources, including induction, gas, and electric stoves. For induction cooktops, the aluminum core is often surrounded by a layer of ferromagnetic material such as stainless steel. This makes the cookware suitable for induction cooking.

Versatility

The aluminum core is used in various cookware, including pots, pans, skillets, and woks. This makes it a versatile choice for home and professional kitchens.

Cost-effectiveness

Compared to other materials, aluminum is more affordable. This makes cookware with aluminum cores a cost-effective option for manufacturers and consumers. It helps produce high-quality cookware at a competitive price.

Cookware:

Aluminum core cookware is a popular kitchen product among chefs and culinary enthusiasts. Wholesale buyers looking to stock a range of cookware sets can opt for aluminum core stainless steel pots and pans. These offer excellent heat distribution and even cooking. Some brands manufacture aluminum core nonstick frying pans and skillets. The nonstick surface makes them easy to use and clean for buyers seeking convenience in their cooking.

Automotive Parts:

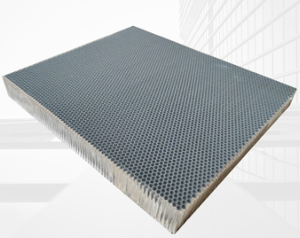

Automotive manufacturers require aluminum core components for various applications. Business buyers of automotive parts may order aluminum core brake discs and rotors. These provide reliable braking performance. They also reduce weight and improve fuel efficiency. Another common product is aluminum core engine components such as oil pans and timing covers. Buyers can also find aluminum honeycomb panels used in automotive interiors and doors.

Building Materials:

Aluminum honeycomb panels are popular among architects and construction companies. They are used in the facades of commercial buildings, which are lightweight and durable. Some manufacturers offer panels with glass or stone veneers. This meets the aesthetic needs of luxury hotels and retail stores. Other applications of aluminum panels are in interior walls, ceilings, and partitions.

Heat Exchangers:

Business buyers of industrial equipment order aluminum core heat exchangers. This is because aluminum is a good conductor of heat. It is also lightweight and resistant to corrosion. Aluminum core heat exchangers are used in various industries such as HVAC, automotive, and oil and gas. Some manufacturers offer custom-built heat exchangers. These are tailored to meet specific buyer requirements.

Sports Equipment:

Wholesale buyers in the sporting goods industry can source products with aluminum cores. For instance, aluminum core hockey sticks and baseball bats have a popular appeal among athletes. Aluminum core skis and ski poles are also common in winter sports. Aluminum is valued for its lightweight and rigid properties in these applications.

Before choosing aluminum core manufacturers, it is important to consider several things. First, one should check the quality of the products. A good manufacturer should be producing quality aluminum core products. Buyers can check reviews from previous customers to see if the manufacturer produces quality products. They can also check the materials used by the manufacturer to see if they are quality.

Another thing to check is the manufacturing process. It is important to know the manufacturers' production process to ensure they are using the right techniques to produce the aluminum core. Buyers can go a step further and visit the manufacturers' premises to see everything in action.

It is also important to check the certifications and standards of the aluminum core manufacturer. A good manufacturer should have all the required certifications and should be following all the required industry standards. The manufacturers should also have a quality control process to ensure everything is working perfectly.

The delivery time of the aluminum core manufacturer is also a crucial factor to consider. Buyers should get manufacturers who will deliver the products on time. As a buyer, it is important to communicate your needs to the manufacturer so they can produce the aluminum core products within the required time.

Customer support is also important when choosing an aluminum core manufacturer. Buyers should get manufacturers with a good customer support team who will be there to answer any question when needed. A good customer support team will be there to offer assistance in case there is a problem with the product.

Lastly, the price of the aluminum core products should be reasonable. Buyers should get manufacturers who offer fair prices without compromising the quality of the product. It is important to work within the budget when choosing aluminum core manufacturers.

Q1: What is a metal core in a cookpan?

A1: A metal core or base is the layer that makes up the bottom of a cookware item. It usually consists of two or more bonded layers of different metals designed to provide even heat distribution and stability when cooking.

Q2: What are the different kinds of cookware cores?

A2: Cookware items have single or triple metal cores. The latter consists of stainless steel, aluminum, and sometimes copper. The single cores usually feature aluminum or copper, which enhance heat conductivity.

Q3: What is the significance of a metal core?

A3: A pot or pan with a metal core ensures that heat is distributed evenly across the cooking surface. As a result, this prevents hot spots and ensures food is cooked thoroughly and uniformly.

Q4: What are the shortcomings of aluminum?

A4: While aluminum heats up quickly and is lightweight, it is not very durable. Cookware made from this material alone will warp easily. Also, aluminum reacts with acidic and alkaline foods, altering the taste of the food being cooked.

Q5: What are the advantages of having an aluminum core?

A5: An aluminum core allows for lightweight cookware that can conduct heat quickly and uniformly. The metal core also stabilizes the cookware, preventing it from warping when exposed to high temperatures.