(16667 products available)

Air hoses for compressors are flexible tubes that transport compressed air from the air compressor to various tools and equipment. They are essential for any pneumatic system. The hoses come in different sizes and lengths. The choice of air hose depends on the application and the distance between the compressor and the tool. The function of air hoses is to deliver air pressure to power tools like nail guns, impact wrenches, spray guns, and air blowers.

Air hoses for compressors come in various materials, diameters, and lengths. The most popular materials are polyurethane, PVC, and rubber. They are also available in different diameters. The inner diameter of the hose will affect the amount of air delivered to the tool. A smaller diameter will deliver less air than a larger diameter. Hoses also come in different lengths. The longer the hose, the more pressure lost due to friction. Choosing the right size is crucial to prevent under or over powering the air tools.

There are many types of air hoses for compressors. They include:

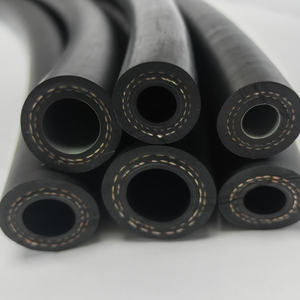

Rubber Air Hose

Rubber air hoses are the most popular choice among users. They are long-lasting and highly flexible, making them ideal for heavy-duty applications. The rubber material allows the hoses to withstand extreme weather conditions. They can operate in both high and low temperatures. Also, they are resistant to abrasion and won't kink easily. However, they tend to be heavier and more expensive than other materials.

PVC Air Hoses

PVC rubber is a popular choice for homeowners. It is lightweight and more affordable than most materials. It is easy to handle and coil, making it ideal for small workshops and home use. The hose is usually available in bright colors for easy visibility. Some hoses have a braided reinforcement that makes them more flexible. However, they are less flexible than other hoses when exposed to low temperatures.

Polyurethane Air Hoses

Polyurethane air hoses are lightweight and highly flexible. They are ideal for applications that require frequent movement. The hoses have a smooth interior that allows air to flow freely. They are also resistant to abrasion and punctures. Some of them can be kinked resistant. However, they tend to be more expensive than PVC hoses.

Coiled Air Hose

Coiled air hoses are spiral-shaped and compact. They are made from polyurethane or PVC. The hoses are ideal for small workspaces since they occupy little space. When not in use, they can easily be stored. The design prevents the hose from being tangled or kinked. They also promote better air circulation. However, they have a limited working range due to their coiled nature.

Material Durability:

Rubber: These air compressor hoses are known for their flexibility and ability to operate in extreme conditions. Rubber hoses are enduring and can be bent around corners without breaking. They are also resistant to UV light and ozone.

Nylon: These hoses are lighter than rubber and become more flexible when wet. They are resistant to abrasion and work well at high pressure.

Polyurethane: These air hoses for compressors are popular because of their lightweight nature. They are flexible and can be made in different colors. Polyurethane hoses have low friction and are resistant to abrasion and puncture. They also work well in cold weather.

Diameter and Length:

The internal diameter of the hose affects airflow and pressure. A wider hose allows more air to flow, while a narrower hose increases pressure. Hoses come in different lengths. Longer hoses give you a larger working area, but they reduce pressure slightly. Shorter hoses are more efficient at maintaining pressure.

Temperature and Pressure Rating:

Every compressor air hose has a maximum temperature and pressure it can safely handle. It is important to choose a hose that matches the temperature and pressure of the air compressor to avoid risks. Rubber hoses usually have higher pressure ratings.

Couplings and Fittings:

These are the connectors on the hose ends. They are important for connecting the hose to the air compressor and tools. Fittings are made from materials like brass or steel. Couplings allow for quick connection and disconnection of hoses and tools.

Special Features:

Some air compressor hoses have a spiral design that makes them easier to store and prevents tangling. Retractable hoses automatically wind back into a reel when done, while reinforced hoses have extra layers for durability. Many hoses have a safety factor of 3, which means they can handle three times their rated pressure.

Automotive Maintenance and Repair

Compressor air hoses are widely used in the automotive industry for various maintenance and repair tasks. Mechanics use air hoses to connect pneumatic tools such as impact wrenches, tire changers, and ratchet sets. These tools speed up tasks like changing tires, loosening bolts, and general tire maintenance. Also, air hoses are used for airbrush painting vehicles and spraying touch-up paints.

Construction Sites

Air hoses for air compressors are common in construction sites. They are connected to various pneumatic construction tools such as nail guns, jackhammers, and sledgehammers. This enables the quick and efficient assembly and disassembly of structures. In the construction site, air hoses are also used to power compactors and blowers.

Manufacturing Industry

In the manufacturing industry, compressor air hoses are used to power various pneumatic tools like drills, saws, and grinders. These tools are essential in the manufacturing process. Also, they are used in material handling systems such as air-powered conveyor belts and suction cups for lifting and moving materials.

Agriculture

Compressor air hoses are used in farms and agricultural activities. They are connected to pneumatic tools for tasks like tilling, planting, and harvesting. Also, they are used to operate air seeders and grain vacs for efficient seed planting and grain harvesting. Moreover, air hoses are used to inflate tires of agricultural machinery and implements.

Woodworking Shops

Air hoses for air compressors are essential tools in woodworking. They are used to operate pneumatic tools such as nailers, staplers, and sanders. This enables faster and precise fastening of wood joints and sanding. Additionally, these hoses are used to clean wood dust and debris from work surfaces and machinery.

HVAC Installation and Maintenance

Air hoses are used in the HVAC industry to operate pneumatic tools for ductwork installation and maintenance. For instance, air-powered crimpers and presses enhance the construction and installation of HVAC systems. In addition, air hoses can be used to test air duct systems for leaks and repairs.

Laboratories and Workshops

Air hoses for compressors are widely used in laboratories and workshops. They are used to power various tools and equipment like microscopes, centrifuges, and air-powered vices. In workshops, air hoses are used to operate tools like file, hammers, and chisels. They are also used for cleaning and blowing away debris in laboratory setups.

Choosing the right air hose for a specific application involves considering various factors to ensure compatibility and optimal performance. Here are some factors to consider before purchasing air hoses for a compressor.

Compressor Compatibility

The first thing to check is whether the air hose is compatible with the compressor. Compatibility includes checking whether the hose can handle the compressor's maximum pressure without bursting. Also, check if the hose diameter is compatible with the compressor fittings.

Material and Construction

Different materials offer various flexibilities, resistances, and durability. For example, rubber is flexible and durable, while polyurethane is lightweight and kink-resistant. Choose a material that meets the user needs and application requirements.

Application Requirements

When buying air hoses for a specific application, consider the operating environment. Users should choose air hoses that can withstand the environmental conditions expected, such as extreme temperatures, UV exposure, and chemicals. Also, check the hose diameter required for different tools, as some tools may need a larger diameter for adequate airflow.

Length

The length of air hoses can affect pressure. Longer hoses may experience higher pressure drops. Therefore, it is important to choose a length that is long enough to reach the desired area without compromising pressure. Also, consider the space available for storage and handling when choosing the length.

Weight

The weight of an air hose affects portability and ease of use. Lighter hoses are easier to move around and handle, making them suitable for portable applications. However, heavier hoses are often more durable and resistant to external damage. Users should find a balance between durability and portability when considering the weight.

Hose Fittings

The hose fittings connect the compressor, hose, and tools. It is important to choose the right fitting to ensure a secure connection. Various types of fittings are available in the market, such as threaded, quick-connect, and barbed fittings. Also, the size and type of fitting directly impact the flow rate and pressure.

Q1: What is the best length for an air hose for a compressor?

A1: A long air compressor hose can reduce pressure, so shorter hoses are better for tasks that require high pressure. However, if the hose has a smaller diameter, it can still be long without losing pressure. The work to be done will determine the length of the hose. For example, a 50-foot hose is suitable for light tasks, while a 100-foot hose is ideal for heavy-duty tasks.

Q2: What do air hoses deteriorate?

A2: Air hoses can deteriorate due to exposure to extreme temperatures, UV rays, and ozone. Extreme temperatures can cause the hose to become brittle or soft, while UV and ozone rays can cause the outer cover to crack.

Q3: What is the best diameter for an air hose?

A3: An air hose with a 3/8 inch diameter is suitable for most air tools. It provides adequate airflow for pneumatic tools like sanders and impact wrenches. A 1/4 inch hose can also be used for small air tools but is not ideal for larger air tools.

Q4: Do air hoses lose pressure over distance?

A4: Yes, the air compressor hose can lose pressure over distance due to friction. The longer the hose, the more friction the air supply will encounter, thus reducing pressure. That's why it is recommended to use a more narrow hose for longer distances to counter pressure loss.

The keyword "air hoses for compressor" has maintained a consistent average monthly web search volume of 12,100 over the past year, despite a notable -45% decrease in the last three months. This stability, however, was punctuated by a significant spike in July and August 2024, where web searches doubled to 22,200 before reverting to the annual average.

Analyzing the trend in detail, the keyword experienced minimal fluctuations throughout most of the year, with the exception of March 2024, which saw a reduction to 9,900 web searches. This pattern of stability was abruptly interrupted by the aforementioned peak in mid-year, indicating a possible seasonal influence or market event that temporarily increased interest in air hoses for compressors.

This web search volume data reflects a generally steady interest in the product category, with the observed dip and subsequent spike providing intriguing insights into potential market dynamics or external factors influencing consumer search behavior. The consistent web search volume throughout most of the year suggests a solid, ongoing demand, while the sharp increase in mid-year highlights a period of heightened interest that could be attributed to various market activities or seasonal projects requiring the use of compressors.