(1891 products available)

When looking for adjustable steel shoring jacks for sale, it’s important to know the different types to make an informed purchase. Below are the various types of adjustable shoring jacks:

Folding Shore Prop:

These are adjustable shore props that fold in half. They are used when there is a need for temporary support on construction projects. Since they can be folded, they are easy to store and transport when not in use. They support beams and walls during construction and are commonly made of steel, which is durable and strong.

Scaffold Shore Prop:

These are shore props used in scaffolding. They are used to provide temporary support for building projects. They are made of steel or aluminum and are commonly used in construction because they are lightweight, versatile, and durable. They come in different sizes, and their length can be adjusted to fit different support needs.

Acrow Shore:

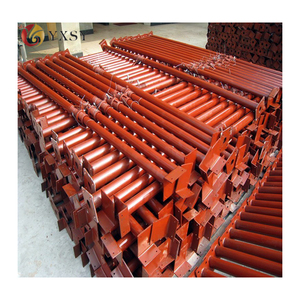

These are adjustable steel shoring jacks used to support beams and structures during construction. They are made of steel, which is strong and durable, and they come in different sizes. They are commonly used to support walls and ceilings in the construction of buildings. They are easy to install and remove and have an adjustable length.

Aluminum Shore Props:

These are shore props constructed of aluminum. They are lightweight and resistant to rust. They are used to support structures temporarily during construction. They are popular in construction projects because they are easy to transport and install and provide the necessary support. They can be adjusted to fit different lengths and are durable.

Heavy-Duty Shore Props:

These are shore props constructed with heavy-duty materials. They are used when there is a need for heavy lifting and support in construction. They can support a lot of weight and are suitable for large construction projects. They are adjustable and can be used to support different structures and materials. They are durable and require minimal maintenance.

Adjustable steel shoring jacks are props for concrete work that provide temporary support to structures. Their adjustable nature allows them to support beams, columns, or anything in between. These shoring jacks have become integral in the construction industry due to their versatility and dependability.

These shoring jacks have become integral in the construction industry due to their versatility and reliability. Below are some features and functions of these shoring jacks:

Load Bearing Capacity

Steel shoring jacks are designed to support significant loads. Depending on the design, material, and size, these jacks can support loads of up to several tons. The load-bearing capacity ensures that they can be used in various construction projects, from residential to commercial and even infrastructure projects.

Height Adjustment

These shoring jacks can be adjusted to different heights. This is done through a telescoping mechanism that allows the jack to be extended or retracted. Height adjustment allows these jacks to be used in different applications regardless of the height of the structure being supported.

Robust Construction

Adjustable steel shoring jacks are made of durable and robust materials. Usually, they are made of galvanized steel or high-strength steel. The construction allows them to withstand harsh weather conditions and also resist deformation or failure under pressure.

Easy Installation and Removal

Installation and removal of shoring jacks are straightforward. They usually have a screw mechanism or a quick-locking system that enables easy adjustment and secure installation. Once the construction is complete, removing these jacks is usually just as easy as installing them, making them a convenient temporary support solution.

Stability and Safety

These jacks are designed to provide a stable and secure support system. They usually have a non-slip plate or base that distributes the load and prevents sinking or tipping. Additionally, these jacks often have safety pins or clips that secure the adjustment in place and prevent accidental collapse.

Versatility

Shoring jacks are versatile since they can be used in various applications in different sectors. They are commonly used for shoring walls, supporting beams and rafters during construction, underpinning foundations, and even in emergency structural repairs. Their versatility makes them an essential tool in the construction industry.

The demand for shoring jacks in construction is quite high due to their vital role in providing structural support and stabilization. Their adjustable nature makes them suitable for various applications. Below are some common usage scenarios:

Structural Support

Steel shoring jacks provide temporary support to beams, columns, and walls. This is especially during construction, renovation, or structural reinforcement. Their load-bearing capacity ensures a safe redistribution of weight to the ground or foundation. This minimizes the risk of settling or shifting.

Vertical Alignment

These jacks are used to ensure vertical alignment of structural elements during construction. Their adjustable nature allows fine-tuning placements of beams and columns. This ensures they are perfectly vertical before the permanent supports are installed.

Load Transfer

Shoring jacks are crucial in load transfer operations. They can be used to transfer loads from compromised structural elements to the ground. This allows for safe removal or repair of the compromised elements. Load transfer systems enhance the safety and stability of the entire structure.

Temporary Stacking

These jacks facilitate temporary stacking of materials such as masonry units, formwork, and precast elements. This allows for efficient construction sequencing and material placement. Temporary stacking reduces the need for additional support structures, thus saving time and costs.

Shoring to Foundations

Adjustable steel shoring jacks can be used to shore up to the foundations. They provide temporary support to above-ground structures when excavating for new foundations or performing foundation repairs. This allows deep excavation and foundation work to be completed safely without collapsing the existing structure.

Interior Shoring

Interior shoring involves the use of shoring jacks to support interior walls, ceilings, and floors. This is in large-scale renovations or remodeling projects. The jacks allow selective demolition and structural modifications of interior elements without compromising the overall structure.

Propping of Slopes and Excavations

These jacks can also be used to prop up slopes and excavations. They provide support to the slopes and walls of excavated sites in order to prevent collapses. The jacks are placed at strategic locations along the excavation sites and sloped ground to ensure stability.

When choosing the right adjustable steel shoring jack for a specific project, it is essential to consider several factors to ensure safety, stability, and structural integrity. Here are some of them:

Load Requirements

The primary consideration should be the load requirements. Determine the maximum load each shoring jack will support. Consider factors like the height of the structure, the weight of the materials being supported, and environmental conditions. Choose shoring jacks with load capacities above the required amount. This ensures they can safely support the structure during construction.

Height and Length Adjustability

Consider the height and length adjustability of shoring jacks. Look for jacks with telescoping capabilities. They allow height adjustments to accommodate different construction site requirements and terrain variations. Ensure the shoring jacks can be securely extended to the needed length and height without compromising stability.

Material and Durability

The material and durability of adjustable shoring jacks are factors that determine their performance and lifespan. Opt for shoring jacks made of high-strength steel. They offer enhanced durability and resistance to deformation under heavy loads. Look for jacks with a galvanized or powder-coated finish. This provides protection against rust and weather elements, especially in outdoor or humid environments.

Base Plate and Footing

The base plate and footing play a critical role in the stability of shoring jacks. A larger base plate size distributes the load over a wider area and provides more stability. Ensure the shoring jacks have quality and robust base plates. Consider the type of footing required for different soil conditions and load specifications.

Ease of Use

Shoring jacks should be easy to operate and adjust. Consider the ease of assembly, disassembly, and adjustments on-site. Look for jacks with user-friendly mechanisms and minimal required tools for adjustments. Also, consider the weight of the shoring jacks. While steel is durable, aluminum shoring jacks are lighter and easier to handle on construction sites.

Safety Features

Ensure the steel shoring jacks have robust safety features. Look for shoring jacks with locking mechanisms, such as safety pins or collars. They prevent accidental sliding or collapsing under load. Also, consider jacks with load indicators. They ensure the shoring jacks are operating within the safe load limits.

Q1: Are adjustable steel shoring jacks safe to use?

A1: Yes, shoring jacks are safe if they are properly installed and maintained. The jacks should be installed by a professional to ensure safety.

Q2: How to maintain adjustable steel shoring jacks?

A2: The shoring jack should be cleaned and lubricated regularly. It should also be inspected for any signs of damage or wear out. The jacks should be professionally maintained to ensure they are in good working condition.

Q3: How much weight can shoring jacks support?

A3: The weight capacity of the shoring jacks varies depending on the size and design. Shore jacks can support a weight capacity of 10,000 pounds or more.

Q4: Can shoring jacks be used on uneven ground?

A4: Yes, shoring jacks can be used on uneven ground. The adjustable jacks can be adjusted to fit different heights and levels.

Q5: Where can shoring jacks be purchased?

A5: Adjustable steel shoring jacks can be purchased from construction equipment retailers or online marketplaces. It is important to buy from a reputable manufacturer to ensure quality and durability.