(5473 products available)

A b rivet comes in various types, each tailored to specific material-joining needs. Understanding these types helps in selecting the right rivet for a given project.

Blind Rivets

Blind rivets, also called pop rivets, are exceptional where only one side of the material is accessible. They work by having the setting tool (rivet gun) on one side while the rivet holds the material from the other side. Blind rivets are widely used in construction and automobile areas.

Solid Rivets

Solid rivets remain the most traditional. They require access to both sides of the material for installation. Solid rivets are mostly hammered or heated to drive the rivet. They are ordinarily used in aerospace engineering with heavy machinery fixation where strong joints are vital.

Split Rivets

Split rivets feature a head with a split or slot aimed at spreading as the rivet is driven. This design provides a strong holding, mainly on soft materials including leather and wood. Commonly, these rivets are seen in the manufacture of furniture and other decorative elements.

Tubular Rivets

Tubular rivets have a hollow body, which makes them lighter than solid rivets. They are ideal for use in materials that require less strength or where only one side is accessible. Applications normally include thin cloth and plastic repair; they also serve well in the lightweight construction where an extensive fastening is still needed.

Drive Rivets

Drive rivets are a one-piece fastener designed in such a way that the legs of the rivet spread apart when driven, providing a strong secure joint. Their ease of installation allows them to be mostly used in thermoplastics and metal sheeting roofing.

Heavy-Duty Rivets

These rivets are large in size and are typically used in structural applications. They offer premium strength and durability when compared to conventional rivets. Structures, bridges, and other industrial constructions generally include heavy-duty rivets.

The essential function of a metal rivet is to join two or more materials through the application of compressive forces. Unlike screws, which twist into materials, rivets are inserted and then deformed (or "set") to create a permanent mechanical bond.

A rivet is a versatile tool, mainly used not only for fastening but also improving joint integrity when applied in mechanical construction. They are key features and functions that make them necessary in various engineering applications.

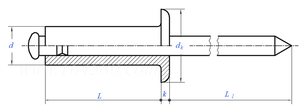

The typical design of a rivet is composed of a smooth cylindrical shank, with a head at one end and the other end forming a tail. When setting a solid rivet, the tail flattens out. Blind rivets are also designed to include a mandrel that pulls through the rivet body and breaks at a pre-determined tension.

Rivet sizes are defined mainly by shank diameter and length. Larger diameters increase the joint's strength, thus increasing the joint area. Choosing the right rivet size is crucial in any application since it ensures complete load distribution and avoids material failure.

Heads may also be in different shapes, including flat, round, or pan. Each head shape offers various gripping surfaces in line with the material or tool being used to drive the rivet.

A b rivet has numerous industrial applications reflecting the fastener's versatility and robustness. Below are some of the most popular scenarios in which these rivets are employed.

Aerospace and Aircraft Manufacturing

Rivets in the aircraft construction provide a vital role in joining the aircraft skin to underlying structural components. Many of these rivets also need to meet rigorous safety and strength standards due to the association with a major aeronautical engineering. Aluminium rivets tend to be lighter and corrosion-resistant, making them ideal for this industry.

Automotive Industry

A rivet is a predominant fastening used for automobile body panels, particularly where welding is not feasible. For instance, in riveting the roof panels and doors, they provide an even distribution of loads without causing distortion to the underlying structures. Pop rivets possess special regions of automotives built with materials that do not require access on both sides.

Sheet Metal Work

A b rivets are common fasteners used in sheet metal construction. They hold two or more sheets together and are most useful where the joint bearing must be strong enough to carry the weight of the overlying sheet with no access through the back. HVAC ducting, roofing, and cladding in construction often employ riveting for enhanced joint strength.

Marine Applications

Rivets are widely used in constructing boats, ships, and other marine structures, working against the destructive effects of corrosion, salt, and moisture. Stainless steel and aluminium rivets are common in this business. These materials are corrosion-resistant and give a permanent fixation of the joints, possessing durability for extreme marine conditions.

Furniture and Woodworking

Split and tubular rivets mostly find usage in the furniture sector; they are primarily used in the fixing of leather, plastic, and upholstery fabrics. They provide a robust bond while maintaining the targeted aesthetic. Moreover, in woodworking, rivets attach hinges, handles, and other accessories.

A b rivet selection depends on several key factors that business owners and procurement agents should consider. Material choice, rivet type, size, and quantity affect the effectiveness and efficiency of any riveting project. Here are the main considerations when choosing a b rivet.

Rivet Material

Rivet material must match the application requirements and the base materials to be joined. Rivets made of aluminium are lightweight yet sturdy and are ideal when used for manufacture in aircraft and automobiles. Stainless steel rivets act like a permanent fastening in places where corrosion could occur. Stainless steel rivets also provide anti-corrosive properties.

Mild steel rivets provide exceptional strength; where rivets are set with a hammer, these robust but low-cost rivets are often used in engineering work, though they must be painted or plated to avoid rusting.

Brass rivets possess excellent corrosion resistance and are also easy to work with. Usually, these are found in electrical applications due to their non-magnetic and corrosion-resistant features.

Rivet Type

Business owners should buy blind rivets to cater to customers who work on projects with access to one side of the workpiece. They should stock solid rivets for industries that require heavy-duty fastening, as well as split rivets for projects that require lightweight materials.

Rivet Size

Choose the right rivet diameter and length to ensure proper joint performance. Rivet diameter corresponds to the hole sizes commonly drilled in the workpiece. Rivet length should be equal to the total thickness of the materials being fastened, plus the head. For thicker assemblies, longer rivets are needed. Conversely, shorter rivets work well in thin constructions.

Rivet Quantity

Rivet requirements mainly depend on the projects' scale. In large-scale construction, bulk purchases are cost-effective. Pay attention to any possible future needs as well. Keeping extra rivets on hand guarantees fast production line flow and prevents disturbing work.

Strength and Load-Bearing Capacity

When making a rivet choice, consider the strength and load-bearing capabilities of the rivet. Heavy-duty rivets should be used in structural applications requiring high load support. Projects requiring joint integrity under weight factors should not use low-strength rivets.

A1: Solid rivets are the strongest type. They provide the strongest joints compared to other rivet types because they are hammered or heat-treated, which deforms the metal and creates a very tight, strong bond between the materials.

A2: Aluminium rivets are predominantly used in automotive and aerospace industries. They are lightweight, strong, and resistant to corrosion, making them ideal for joining materials without adding significant weight.

A3: The main difference between the two rivets is that solid rivets must be hammered or weighted on both sides of the material. Blind rivets are designed to be installed from one side only. That requires no access to the back side for setting.

A4: Copper rivets are commonly used in leatherworking. They serve fastening components in electrical applications due to corrosion resistance. Also, they are malleable, which allows them to be easily shaped without breaking.