(10696 products available)

Silicon carbides come in different varieties based on the structure needed, the way it is prepared, and its particular function. Hence, the five silicon carbide types can be based on the aesthetically appealing features or the structure of the silicons carbide crystals:

Imperfectly Faceted

This type of silicon carbide crystal has bound crystals because of contained dislocations. Even though the flaws are visible, they do not significantly impact the material's functionality. In technical applications where the crystal's movement feature is not important, imperfectly faceted crystals can be acceptable. They can be used to build components that do not require more strength.

Polytypic Facets

These crystals are a characteristic of silicon carbide materials, which form in distinct structural forms, also called polytypes. Every polytype facet has a distinct stacking sequence of the atomic layers, leading to the formation of crystals with various physical and chemical properties. For example, 3C-SiC, 4H-SiC, and 6H-SiC are common polytypes of silicon carbide. They are usually used in electronic devices. This might also include crystals with polytypic facets for enhanced mechanical characteristics or thermal resistance.

Flaw Facets

Flaw facets are the areas on the crystal surface that have flaws or defects in the form of cracks, scratches, or foreign inclusions. On the other hand, flawed facets can be a great temptation for applications in which the crystal quality is not critical for factors like infrastructure or manufacturing of composite materials. In this case, the appearance of silicon carbide looks appealing, but functionality requires low values of crystal quality.

Monocrystalline Facets

Monocrystalline silicon carbide facets are perfect for high-quality silicon carbide crystals with a single, continuous crystal structure. These crystals are typically characterized by high strength, exceptional thermal and chemical stability, and a high level of conductivity. Therefore, they are widely used in electronic and optoelectronic devices. Moreover, due to their outstanding mechanical properties, they also find uses in high-performance abrasives.

Brilliant Facets

These facets indicate that the crystal has high-quality shine with minimal roughness on the top. Such characteristics indicate that the crystal structure is ordered, and there aren't many dislocations or defects. It is primarily a morphological character of the diamond and other gemstones. SC silicon carbide crystals are also used in electronic devices, which demand premium crystal quality.

Power generation

Silicon carbide's unrivaled capacity to withstand high temperatures, coupled with its exceptional structural stability, positions it as an excellent choice for power generation systems. Such systems include gas turbines and combined cycle power plants, which operate under extreme conditions. Therefore, using silicon carbide components in these systems improves operational efficiency and durability.

Aerospace and Gas Turbines

In the aerospace sector, silicon carbide plays a crucial role in manufacturing components for jet engines and rockets. Which improves weight-to-strength ratios while ensuring reliability in harsh flight conditions. As a result, in gas turbines, silicon carbide is used to produce seals, blades, and other critical components that can endure the elevated temperatures and stresses encountered during combustion.

Ceramic Kilns and Furnaces

Silicon carbide bricks serve as the backbone of kilns and furnaces in the ceramic and metallurgical industries, where excessive heat is an everyday occurrence. These bricks resist thermal shock, wear, and oxidation, thereby creating a long-lasting lining that promotes effective and safe operation. In foyers meant for metals, silicon carbide materials ensure the longevity of the structure against molten metal and slag.

Steelmaking and Foundries

Silicon carbide is now becoming trendy in the steelmaking sector, particularly in blast furnaces and converters. Its ability to function as a refractory material improves heat containment and enhances the reduction process. In foundries, SiC particles are used to manufacture casts and molds that can withstand pouring temperatures with high alloy effectiveness.

Semiconductors and Power Electronics

In this era, silicon carbide substrates have immense importance in power electronic devices such as MOSFETs and diodes. These devices can operate at extreme temperatures, voltages, and frequencies; they are suitable for electric vehicles, renewable energy systems, and industrial motors, which improves their efficiency and effectiveness.

Electronics

Silicon carbide is widely used in optoelectronic devices, including light-emitting diodes (LEDs). Such LEDs have superior brightness and energy efficiency. Blue and UV light emission devices use silicon carbide substrates in making a wide range of applications that go up to the fields of medicine and data storage.

Sensors

SiC is used to manufacture temperature and pressure sensors for aerospace and automotive applications. Therefore, sensors made from silicon carbide can function reliably in high-temperature settings, retaining accuracy and durability in environments that would degrade other materials.

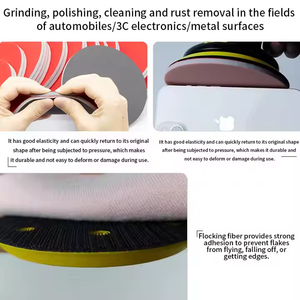

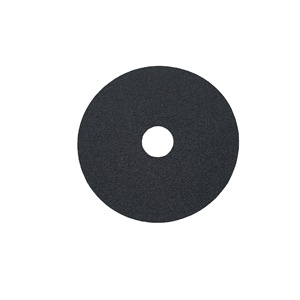

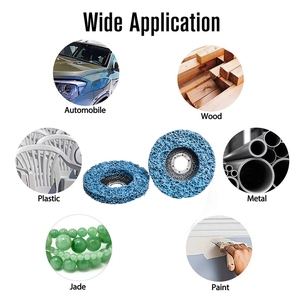

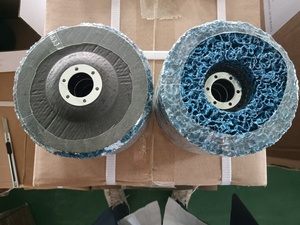

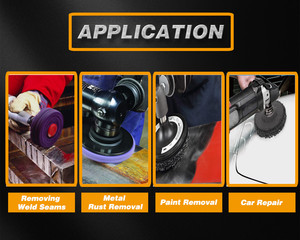

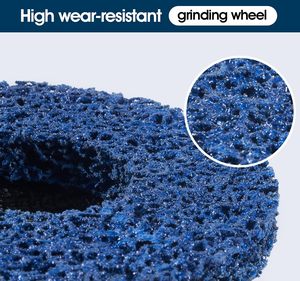

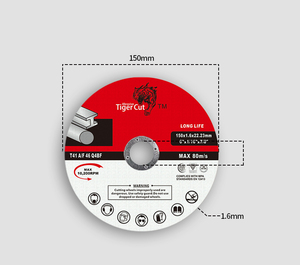

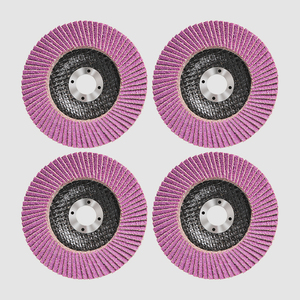

Abrasive Discs and Wheels

Silicon carbide grains are widely used in abrasive wheels and discs to cut, grind, and polish hard materials such as ceramics, metals, and hardened steel. These tools are valued for their sharpness and durability; they ensure efficient machining with minimum heat generated.

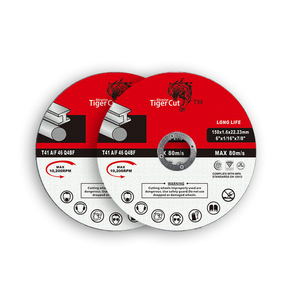

Cutting Blades

Silicon carbide is the ideal material for making cutting blades for diamond cutting knives and precision work. These blades outperform conventional materials in cutting hard, brittle substances such as granite, marble, and glass. Thus, this makes them an important tool in the construction and stoneworking industries.

Wear Parts

Silicon carbide's exceptional hardness and wear resistance make it an ideal material for manufacturing cutting tools. Things like drills, inserts, and tool holders encounter wear due to abrasion in tough machining conditions. Hence, tools with silicon carbide tips or parts have a longer lifespan, improving efficiency and reducing frequent tool replacement.

Five types of silicon carbide (SiC) exhibit remarkable characteristics and properties due to their unique crystalline structures. Each material is commonly used on a large scale in the electronics industry because of its mechanical, thermal, electrical, and optoelectronic properties.

3C-SiC

3C-SiC, a cubic crystal structure silicon carbide polytype, has gained popularity, especially in the semiconductor industry. Its relatively high electron mobility makes it suitable for power electronic devices, like MOSFETs and diodes. In addition, 3C-SiC can be grown on silicon substrates, integrating it into existing silicon manufacturing processes.

4H-SiC

4H-SiC, with its hexagonal crystal structure, is renowned for its epitaxial growth ease. This polytype possesses excellent electric field strength, high charge carrier mobility, and widespread usage in power electronics.

6H-SiC

6H-SiC features a hexagonal crystal structure like 4H-SiC but with a lower band gap. Although the mobility is slightly less compared to other polytypes, 6H-SiC is widely utilized in power devices and high-temperature applications due to its stability and availability.

RS-SiC

RS-SiC contains a stacking fault that induces a rhombohedral crystal structure. Hence, this silicon carbide polytype is less common but valuable in niche applications where specific electromechanical properties come in handy. Its properties mainly depend on the extent and type of the polytypic distribution in the material.

LT-SiC

LT-SiC is essentially low-temperature polytypes. Although it's generally used in research, it has potential uses in electronic devices. Its low-temperature growth conditions make it appropriate for devices requiring low defect density.

Material Quality:

Only silicon carbide belts of the finest quality should be used. The manufacturers of these belts use premium abrasives. They provide immense wear resistance and cutting capability. Prior to purchasing a silicon carbide belt, one should research different manufacturers and read other users' reviews. Purchasing these belts from renowned manufacturers will ensure that only genuine materials were used.

Sanding Discs and Belts

The 100 grit silicon carbide is moderately coarse and suitable for shaping and smoothing surfaces. It removes material at a fair rate for faster stock removal on rough surfaces. The 120 grit silicon carbide is slightly coarser than 100 grit and better for cleaning sharp edges. It prepares surfaces for finer finishes rather than deeper scratches.

Sanding Techniques:

It is recommended to use even strokes with light pressure. This will help do away with overheating the material and prolong the life of the belt. Using excessive force on the belt will produce more friction than necessary. This will cause them to wear faster and might even damage the workpiece.

Protective Equipment:

Working with silicon carbide requires a lot of precaution. Although silicon carbide is tough, it produces harmful dust while wearing out. This dust contains sharp particles that can cause respiratory harm if inhaled. Breathing masks are specifically designed for capturing silica and silicon carbide dust. They are supposed to be worn as the dust generated can cause skin irritation and injuries to the eyes. One should wear gloves and safety glasses when handling the belts or working in an area with a lot of airborne dust.

Dust Control:

All the current tools have built-in dust control. Even with such tools, using additional vacuum systems will help reduce the amount of dust.

Workpiece Monitoring:

Silicon carbide belts generate high heat when sanding. This can cause the workpiece's material to break down; monitoring the temperature is paramount. Stop periodically to check the workpiece. If there's any sign of discoloration or if it's getting too hot, it needs to cool down.

Proper Cooling:

Excessive heat affects both the belt and workpiece. Take short breaks within every few minutes of use to allow both the belt and workpiece to cool down. In situations where they're both overheated, it can cause loss of abrasives and damage to the material.

Disposal:

Dust created during working with silicon carbide can be dangerous to the environment in any way. It needs to be disposed of properly. It also needs to be prevented from going to places where it can affect the environment or harm animals.

Silicon carbide possesses a sharp cutting edge and exceptional hardness. This makes it ideal for cutting tools.

Silicon carbide is popularly used for abrasives, cutting tools, high-performance ceramics, etc.

Due to its high thermal conductivity, silicon carbide is ideal for power electronic devices like MOSFETs.

Silicon carbide is an impressive conductor of heat. This helps dissipe heat and prevents damage.

Silicon carbide enhances the efficiency of electric vehicle motors. This decrease in energy loss extends the vehicle’s range and performance.