(97 products available)

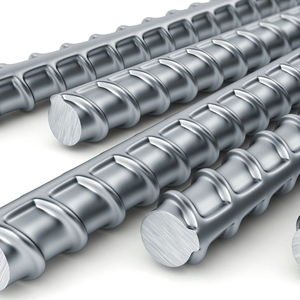

There are several types of 420s steel rebar. These rebars are categorized based on specific mechanical properties such as tensile strength and yield point among others.

Grade 420s fiberglass rebar

This is a high-strength type of steel that is impervious to corrosion due to its fiberglass composition. This makes the barrier lightweight, thus easy to work with. It is also non-magnetic, making it ideal for applications in construction where magnetic interference could pose a problem. It is mostly used for reinforcing concrete in chemical plants, marine structures, and other environments prone to corrosion.

Grade 420s epoxy-coated steel rebar

The steel rebar is coated in a layer of epoxy to protect it from corrosion and adverse weather conditions. The coating provides a barrier against moisture and chemicals: this makes it suitable for areas where concrete is exposed to deicing salts, acidic soils or seawater. The coating is also color-coded, usually in bright shades of green and yellow, helping easily identify the reinforced structures.

Grade 420s stainless steel rebar

Stainless steel rebar consists of an alloy that contains chromium, thus giving it superior resistance to rust and corrosion compared to conventional steel. It is a long-lasting and low-maintenance option for reinforcing concrete in extremely harsh environments such as marine and coastal constructions. This particular rebar maintains structural integrity without any need for painting or retraining that takes up costs and time.

Grade 420s concrete-embedded steel rebar

This rebar is designed with concrete-embedded mechanical anchorage. Its unique design creates a superior bond between the steel and the concrete than conventional rebars. This improves the overall strength and durability of the structure. It is used in high-demand applications such as bridges and industrial floors.

420s steel rebar consists of several distinctive features. They include the following:

High tensile strength

420s steel rebar has elevated tensile strength compared to conventional rebars. This allows it to hold large amounts of tensile stress without warping. This makes it fit for heavy-load applications like bridges, high-rise buildings and parking garages.

Corrosion-resistant

420s steel rebar is highly resistant to corrosion, thus ideal for use in harsh environments. It is made for areas exposed to moisture, salt or chemicals. It enhances longevity as it does not rust. This makes it less prone to structural damage over the years.

Durability

The rebar is much more durable, giving it a longer lifespan than others. It can withstand adverse temperatures, cyclic loading and wear, making it ideal for extended applications. Its durability goes hand in hand with low maintenance requirements—the cost-effective solution in the long run.

Versatility

420s steel rebar is versatile and is used in many applications ranging from residential and commercial construction to infrastructure projects. It can be used in typical and especially exposed environments, ensuring that structural needs and requirements are met in a wide range of applications.

Mechanical Properties

420s steel rebars are hot-rolled and mild steel bars with a standard yield strength of 420 MPa. Their elongation is at least 15%. They are characterized by features like ribs or deformation patterns on the surface to improve bond with concrete.

Choosing the right 420s steel rebar depends on multiple factors. They revolve around the desired application and the conditions it shall be exposed to.

Consider environmental factors

420s steel rebar is preferred in harsh environments such as coastal areas and chemical plants. If the structure will be exposed to moisture, salt, or corrosive chemicals, opt for a type that is not susceptible to corrosion. These include fiberglass, epoxy-coated, or stainless steel rebars.

Application demands

Consider load-bearing requirements. High-strength applications, such as bridges or industrial floors, would benefit from the superior tensile strength of 420s steel rebar. This ensures long-term structural support. Evaluate your specific engineering needs and requirements to ensure the rebar selected meets those standards and is up to code.

Cost versus long-term value

420s steel rebar might have a higher initial cost than conventional rebar. It offers superior long-term value in maintenance and lifespan costs in adverse conditions. Weigh the short-term budget against long-term performance and durability to make a cost-effective decision.

Rebar size and grade

420s steel rebar comes in various sizes and grades. They are determined by standardized systems. Ensure the selected rebar is of the appropriate size with the correct mechanical properties for the project at hand. The commonly used sizes are #4 to #18—the larger the number, the larger the bar.

Consultation with professionals

If in doubt, consult structural engineers or other construction professionals. They will provide insights based on experience and expertise. They may also help ensure the rebar selected meets all code requirements and perform optimally under the expected conditions.

420s steel rebar comes with a myriad of benefits. They impact both the efficiency of the construction process and the longevity of the structures built.

Enhanced strength

The rebar is within the high tensile strength range, which provides superior resistance to bending and warping under heavy loads. This makes it highly suitable for use in heavy-duty structural applications. They include bridges, high-rise buildings, and industrial floors.

Corrosion resistance

420s steel rebar is resistant to rusting and corrosion. This makes it ideal for use in coastal areas and chemical plants where exposure to moisture, salt, and harsh chemicals is inevitable. Corrosion resistance helps preserve the structural integrity of concrete over extended timelines. It reduces the need for expensive repairs or reinforcements.

Durability and longevity

Due to its high strength and corrosion resistance, 420s steel rebar is extremely durable. It has a long lifespan. Structures reinforced with 420s rebar require less maintenance in the long run, providing significant cost savings over time. Furthermore, its exceptional durability makes it suitable for extreme weather conditions as well as seismic regions.

Versatility

It is versatile and can be used in a wide range of construction applications. These include residential, commercial, and infrastructure projects. This adaptability makes it a popular choice among engineers and contractors. They integrate it into various designs. Because it’s available in different sizes, it can easily fit precise engineering requirements, enhancing overall performance in the intended application.

It is typically used in reinforced concrete structures. It is preferable in high- strength and durability applications. These include bridges, high-rise buildings, and industrial floors. In these applications, the rebar offers superior tensile strength. It also resists bending and warping under heavy loads. It is also used in coastal areas and chemical plants where concrete may be exposed to moisture, salt, and harsh chemicals. This is due to its corrosion resistance property which helps maintain the integrity of the structure over time.

420s steel has high tensile strength and corrosion resistance. This makes it ideal for heavy-duty and exposed environment applications. Other grades of concrete reinforcing steel may have lower tensile strengths and be prone to corrosion. Each grade of steel has its own unique yield strength, elongation percentages, and mechanical features to make them suitable for particular construction needs. It is critical to consult a construction professional or engineer. They will determine the grade that is most appropriate for any given construction project.

Unlike conventional rebar, 420s rebar is highly resistant to corrosion and has a higher yield strength. These properties ensure the rebar requires minimal maintenance over its lifespan. This saves, as maintenance costs can be substantial over time, especially in infrastructure. It is also very durable in adverse environmental conditions. This adds to its longevity as a building material. Long-term savings from decreased maintenance and increased durability make it highly cost-effective over its lifespan.

Yes, it is suitable for use in areas prone to earthquakes. Its high tensile strength and resistance to bending and warping make it a dependable choice in seismic zones. Other types of rebar may fail under the stress caused by earthquakes. The 420s rebar will retain its shape and continue to support the structure. Engineering professionals will often have an area’s seismic rating considered when selecting the type of rebar to use as it directly impacts the safety and performance of structures in such areas.