(20 products available)

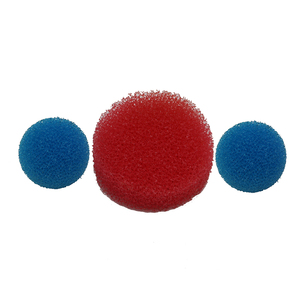

Foam filters are used as a filtration device for air, water, and oil. The device is manufactured in various porosities, with the pores per inch (ppi) being a distinguishing factor in the filters' ability to trap small particles. The 35 ppi foam filter is designed to trap larger particles compared to filters with a higher ppi. Here are some 35 ppi filters with different materials and designs:

Designs:

Square cut foam filter:

Square cut foam filters are generally placed at the intake of an engine or vacuum cleaner. These devices keep dirt, dust, and debris from entering the devices' inner parts. By doing so, they help maintain the efficiency and longevity of the equipment. For example, a lawn mower 35 ppi foam filter is cost effective and can be thrown away once it is dirty.

Precharger:

A precharger is a type of foam air filter, and it works as a first line of defense. This means that it will capture the larger dirt particles and let the air filter capture the smaller ones. A precharger is usually used together with another air filter, and they are used in the filtration of dust in construction sites.

Donaldson Blue air filter:

This filter is mostly used in the automotive industry. It works by allowing clean air in while keeping dirt out. Diesel engines are usually the main users of this kind of filter, especially the ones in trucks. Compared to other filters, a Donaldson air filter has a higher dirt-holding capacity.

Snap/screw-on filters:

These are the most common types of filters in appliances such as refrigerators. The filter is manufactured in such a way that it snaps or screws onto a certain part. This holds the filter in place while the fridge is running.

Materials:

Polyurethane foam filter:

Polyurethane foam filters are used in machines such as lawnmowers and vacuum cleaners. This filter is chosen for its ability to filter fine dust particles. One of the main advantages of this foam filter is that it can be cleaned and reused, which helps reduce waste.

Polyester foam filter:

These filters are often used in low-cost applications where moderate filtration is sufficient. Compared to polyurethane filters, these filters are less effective in trapping dust and dirt.

Neoprene foam filters:

These filters are used when a higher level of durability and chemical resistance is required. Neoprene filters can withstand harsh chemicals and higher temperatures. This makes them effective in applications such as automotive and industrial environments.

The specification of 35 ppi foam air filters describes various features that are critical when selecting the filters for applicatio35ns. They include the air to cloth ratio, dimensions, and material composition.

Regular maintenance of 35 ppi foam air filters is important to ensure optimal filtering performance. Maintenance keeps the air free of contaminants and is the key to prolonging the filter's life. Below are some maintenance tips for 35 ppi foam filters:

Firms that retail pet supplies can use the 35 ppi foam filters in several ways to add value to their products and services.

The following tips will help business buyers to choose the right 35 ppi filter foams for different applications.

Q1: What does PPI mean in filters?

A1: PPI stands for pores per inch. It is a measurement used to describe the density of pores or open cells in foam filter material. Higher PPI means more pores and less fine filtration, while lower PPI means fewer pores and greater firmness.

Q2: What is the 35 ppi foam filter used for?

A2: The 35 ppi filter is often used to filter out large particles or contaminants in various applications, such as air, water, and sound filtration. It is typically used in pre-filters for devices that utilize a 35 ppi foam pre filter, such as air purifiers and vacuum cleaner filters.

Q3: How does a foam filter work?

A3: Foam filters work by trapping particles in the pores of the filter as air, water, or sound passes through the filter material. The filter material's irregular shapes and sizes create a larger surface area for the particles to be trapped.

Q4: What happens when a foam filter is clogged?

A4: When a foam filter becomes clogged with trapped particles, the pore obstruction will restrict a Filtered substance flow through the filter, reducing effectiveness. For foam air filters, breathing obstacles equipment will provide a filtering quality decline. In the case of liquid filters, water or other liquids will not pass through appropriately. Clogging is an indication that the filter needs to be cleaned or replaced.