(661 products available)

Ready to Ship

Ready to Ship

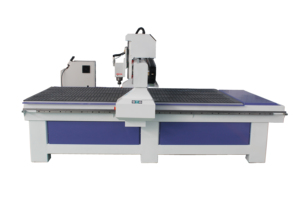

A 3D CNC router has a computer-controlled cutting machine used to cut wood and other materials. It creates three-dimensional objects and designs using a high-speed spindle and various routing bits. There are several types of 3D CNC routers categorized based on their working area, functionality, and design.

Tabletop 3D CNC Router:

A tabletop 3D CNC router is a small machine that can fit onto a desk or benchtop. It is often affordable and is suitable for hobbyists and beginners. This type of router is usually used to cut smaller pieces of materials or create simple projects and prototypes. The user must mount the machine on a stable surface to use it effectively.

Dry 3D CNC Router:

A dry CNC router typically offers a spindle-based machining solution for wood and other soft materials. It may or may not use air cooling or special ventilation to prevent dust from forming during the routing process. This type of router lacks any full dust extraction system but can still perform the routing task with minimal dust and debris professionally and satisfactorily.

Mixed 3D CNC Router:

A mixed 3D CNC router offers the ideal solution for machining a wide range of materials, including wood, plastic, cardboard, sandwich panels, aluminum, and composite materials, among others. This type of CNC machine combines routing and laser technologies or other machining methods within a single system, enabling the simultaneous processing of different materials using diverse machining techniques. For example, the router can carve or cut the material while a laser engraves patterns or designs onto its surface.

Universal 3D CNC Router:

A universal 3D CNC router is designed to handle various materials, including wood, plastic, foam, and soft metal. It is suitable for multiple applications, such as prototyping, sign-making, and manufacturing. The universal router comes in large and small sizes depending on preferences and needs. This type of CNC router often features interchangeable bits and tools to accommodate different material requirements and project intricacies.

Floor-standing 3D CNC Router:

A floor-standing CNC router is a large woodworking machine commonly used in professional workshops and production facilities. Unlike tabletop models, which are small enough to fit on a workspace, floor-standing routers are big and heavy-duty and are designed to stand on the workshop floor. Due to their robust construction and larger machining capacities, floor-standing routers are ideal for handling larger workpieces and more demanding routing tasks.

3D CNC routers come with different specifications depending on their model and make. Generally, they feature a large machine bed or table ranging from 3ft x 4ft to 5ft x 10 ft used to hold down the workpiece material. The repeatability and positioning accuracy of a 3D CNC router also vary by specification. Generally, machines with higher precision produce excellent-quality output with minimal errors. Many routers feature a spacing of ±0.2 mm (±0.01 inch), ±0.5 mm (±0.02 inch), and ±1.0 mm (±0.03 inch). They may also come with a control system that transmits commands to the router unit to move along a particular axis and cut the workpiece material in desired dimensions. More advanced routers feature a computer-aided design system that helps the operator plan the artwork or design on the workpiece material beforehand.

3D CNC Router Machine Maintenance

To maintain a 3D CNC wood router for sale, users must clean all parts of the machine regularly to remove dust, debris, and clippings. Using compressed air or a vacuum can make cleaning hard-to-reach areas easier. They should also lubricate moving parts such as lead screws and rails to reduce friction, ease movement, and prevent accelerated wear. It is important to establish a regular maintenance schedule and stick to it. Users should also inspect components and belts for signs of excessive wear and tear. Regulated oiling and greasing can maximize the lifespan of a CNC 3D router machine. Most manufacturers provide instructions on the ideal lubrication parts and products.

For more advanced routers with computer control systems, keeping the software up to date is essential for maintaining optimal performance. Users should also back up their files from time to time to protect their work from unforeseen circumstances. When operating the machine, they should ensure the routing bit is properly installed and securely fastened. A loose bit can produce an inaccurate and imprecise output. They should also set the correct routing speed and depth for the material at hand. This helps to minimize excessive wear on the bit. If the material requires clamping, they should make sure it is securely clamped to prevent vibrations when routing.

In case of an accident, they should identify and address potential safety hazards, such as sharp moving parts, before they occur. More importantly, they should wear safety equipment like goggles and dust masks to protect themselves from dust and flying debris.

3D CNC routers have numerous applications in various industries due to their versatility and high level of precision.

In the woodworking industry, 3D CNC routers are widely used for intricate carvings and high-quality joinery. This machine is for creating complex 3D designs in furniture, doors, and cabinets. It is also applied in sign making for cutting and engraving signs using various materials such as wood, plastic, metal, etc. The 3D CNC router can precisely create lettering, logos, and designs, which are great for producing high-quality signs.

In the aerospace and automotive industries, 3D CNC routers are often employed for creating mold making for airborne and auto parts. They can cut and shape materials with high accuracy to produce molds for complex shapes and designs. In the jewelry industry, 3D CNC routers are great for carving and engraving precious metals and for materials like wood, resin, and ivory. These machines can create intricate designs, including personalized jewelry pieces, pendants, and bracelets.

3D CNC routers also have educational applications. They are used in schools and universities to teach students about CNC machining and design. With such a machine, students can learn how to create digital designs, program CNC routers, and work with different materials.

When choosing a Cnc device for the job, there are a number of critical factors which will impact the decision. Knowing the job requirements and material types beforehand will assist greatly in making the right decision. Also, it's worth researching how the Cnc router 3D works.

Understanding the project requirements is the first step to making the right choice. One of the first things to look at is the material type. For example, wood projects will require something different than stone or metal projects. Knowing the material thickness is also very important, as is the level of complexity in the designs. Is project work primarily beginner-level 3D designs or more advanced ones with fine details and clear definitions?

One will also need to know the maximum and minimum dimensions of the type of work one plans to do with the Cnc router. Some routers have large work areas, while others have smaller ones. The ability to get a perfect 3D cut without the need for polishing or any other extra finishing is what sets these machines apart.

Job requirements will vary from user to user, whether industrial-scale purchase or small-scale use. Small-scale designs may benefit from a tabletop Cnc router, while standard, oversized machines will be better suited for industrial use. Other distinguishing features include cutting speed or feed rate, resolution, driver system, spindle power, and bit variety.

The type of bits and blades one plans on using may also be a deciding factor since some Cnc machines are only compatible with certain types of tools. Dust extraction methods will also need to be examined, as clean working areas are essential for achieving the best results.

Q1: What software does a 3D CNC router use?

A1: 3D CNC routers typically use CAD/CAM software to create design files for the routing patterns. The software generates the desired design in a format that can be used to control the CNC machine.

Q2: What materials can a 3D CNC router work with?

A2: 3D CNC routers are capable of working with a wide range of materials. The most common ones include wood, plastic, MDF, plywood, acrylic, PVC, foam, and composite materials. However, the specific compatibility may vary depending the router's design and specifications.

Q3: Can a 3D CNC router cut metal?

A3: Generally, 3D CNC routers are primarily designed to cut and shape softer materials like wood, plastic, and foam. As such, they do not have the power or capabilities needed to effectively cut metal. That said, there exist types of CNC machines such as the CNC plasma router that are designed to cut metal.

Q4: What is the maximum thickness a 3D CNC router can cut?

A4: The maximum thickness that a 3D CNC machine can cut is determined by various factors, including its axis configuration, cutting head design, and available power.

Q5: How fast can a 3D CNC router cut materials?

A5: The cutting speed of a 3D CNC router varies depending the machine's design, motor power, and cutting tool size. Generally, the cutting speed can range from a few millimeters per minute to several thousand millimeters per minute.