(525 products available)

A 2200kv motor, commonly used in small drones and RC vehicles, is a high-speed motor that generates 2200 RPM for each volt applied. It is commonly used in small drones and RC vehicles. It is ideal for applications that require high speed and low torque. There are several types of 2200kv motors available, each suited for different applications and requirements. These are some of the most common ones.

2200kv motors have different types that vary in design, performance, and intended use. Here are some types of 2200kv brushless motors:

Outrunner motors

These are the most commonly used types of brushless motors for high RPM applications. They have their windings mounted inside the stator, which is located in the motor case. They are ideal for applications that require high efficiency and high power output. They are lighter and more powerful and produce more torque at low RPM. They are commonly used in RC cars, planes, and drones.

Inrunner motors

These are another common type of brushless motor for high RPM applications. They have the windings located inside the rotor, which spins around the stator. They are ideal for applications that require low torque and high RPM. They are smaller, lighter, and more powerful and have lower friction losses. They are used in applications such as RC cars and planes.

Coreless motors

These are a type of brushed motor that uses a coreless design for higher efficiency and lower weight. They have a simple design with fewer moving parts, which means less wear and tear over time. They provide a smooth power delivery and have a faster response time. They are used in applications such as micro drones and RC cars.

Sensorless motors

These are brushless motors that do not use sensors to detect the rotor's position. They use a simple electronic speed controller that sends pulses to the motor to determine the rotor's position. They are ideal for applications that require high RPM and low torque. They are smaller, lighter, and less expensive than sensor-based systems. They are used in applications such as RC cars and drones.

Geared motors

These are designed to reduce the motor's RPM while increasing its torque. They have a gearbox that changes the motor's output speed and torque. They are ideal for applications that require high torque and low RPM. They are more powerful and have a longer lifespan because they have more moving parts and can handle higher loads. They are used in applications such as 3D printers and CNC machines.

There are many factors to consider when selecting a 2200kv motor for an application. For instance, one must consider the type of vehicle, weight, and terrain.

Additionally, one must analyze the type of vehicle that is best suited for a 2200kv brushless motor. For instance, 2200kv motors are great for small-scale vehicles like drones, RC cars, and planes. They are able to generate high RPMs with low voltage. Another important consideration is the weight of the vehicle. A high-voltage motor is perfect for a heavier vehicle. This is because it will provide more power. On the other hand, a 2200kv motor works well with lightweight vehicles.

The terrain on which the vehicle will be operated should also be considered. 2200kv motors are ideal for on-road and smooth surfaces. This is because the high RPMs might not be suitable for off-road vehicles, as they will create a lot of wheel spin.

Another important consideration is the battery voltage. The voltage of the battery has to be compatible with the 2200kv motor. Ideally, it should be 6 to 12 volts. Buyers should get a motor controller that matches the motor's specifications. The controller should be able to handle the current and voltage the motor draws.

Apart from that, the gear ratio of the vehicle should be adjusted to complement the 2200kv motor. A higher gear ratio will reduce the RPMs, while a lower gear ratio will increase the RPMs. The gear ratio should be set to achieve the desired speed and torque. Lastly, buyers should consider the cooling system of the motor. 2200kv motors generate a lot of heat, which can damage the motor. Therefore, a proper cooling system such as a heatsink or fan should be installed.

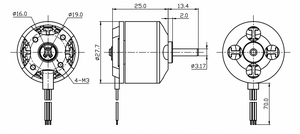

The design of a 2200KV brushless motor essentially comprises a stator and rotor. The stator is the stationary part of the motor that houses the coils of wire. The rotor is the rotating part of the motor that contains magnets. The motor is designed to be compact and lightweight to improve performance and efficiency. In addition, the motor features a durable construction with high-quality materials such as aluminum for the housing and copper for the windings. The motor is also designed with a cooling system that helps dissipate heat generated during operation. This ensures that the motor operates at optimal temperatures, improving its lifespan. The 2200KV motor is also designed to be easily mounted on RC vehicles.

The 2200KV brushless motor has many features that make it popular among RC car enthusiasts. One of the critical features of the motor is its high RPM per volt. This means that the motor can spin faster with less voltage input. This makes the motor highly efficient as it consumes less battery power while delivering more speed. The motor is also known for its high torque. This allows the motor to handle steep climbs and obstacles with ease. Another critical feature of the brushless motor is its smooth and consistent power delivery. This ensures that the motor operates smoothly without any glitches or interruptions.

The 2200KV brushless motor has many functions that make it ideal for RC cars. One of the critical functions of the motor is its ability to provide high-speed performance. This is made possible by the motor's high RPM per volt rating, which allows it to spin faster with less voltage input. The brushless motor is also known for its high torque, which enables it to handle steep climbs and obstacles with ease. Another essential function of the motor is its smooth and consistent power delivery. This ensures that the motor operates smoothly without any glitches or interruptions. Additionally, the 2200KV brushless motor is highly efficient, consuming less battery power while delivering more speed.

2200kv motors have some safety features that protect the motors and improve their efficiency. Here are some common safety features:

Overcurrent Protection

This prevents damage to the motor from excessive current flow. The ESC can detect and interrupt the current flow in case it exceeds a specific limit. This protects the motor from overheating and potential burnout.

Overvoltage Protection

The ESC has overvoltage protection that safeguards the motor from voltage spikes or surges. It ensures that the voltage supplied to the motor remains within safe operating limits. This prolongs the motor's lifespan and improves reliability.

Thermal Protection

This feature protects the motor from damage due to excessive heat. Most motors have built-in temperature sensors that monitor the motor's temperature. The motor automatically reduces power or shuts down when it reaches critical levels. This prevents thermal damage.

Reverse Polarity Protection

This feature prevents damage to the motor and ESC from incorrect wiring or battery connections. It allows the ESC to block current flow in case the battery is connected with reverse polarity. This protects the motor from potential damage.

Short Circuit Protection

This protects the motor and ESC from damage due to short circuit. The ESC can detect any short circuit and disconnect the power supply immediately. This prevents damage to the components and ensures the motor runs smoothly.

2200kv motors have numerous quality features that enhance their performance, efficiency, and durability. Here are some common quality features:

High Power-to-Weight Ratio

These motors offer a high power-to-weight ratio. This means that the motor can produce more power in relation to its weight. This allows for better performance and improved power delivery.

Precision Engineering

2200kv motors have precision engineering that ensures all parts are manufactured accurately and correctly fitted. This improves the motor's efficiency and reduces wear and tear.

Durable Construction

These motors have a robust and durable construction that can withstand harsh operating conditions and high levels of stress. This makes the motor reliable for various applications.

Efficiency

2200kv motors are known for their high level of efficiency. They can convert a significant amount of electrical energy into mechanical power with minimal energy loss. This improves the motor's overall performance.

High RPM Rating

The 2200kv rating indicates the motor can achieve high revolutions per minute per volt applied. This allows for increased speed and better performance in applications that require high RPMs, such as in racing or competitive sports.

Q1: What does KV mean in a brushless motor?

A1: KV is a unit that measures a motor's RPM per volt. It denotes the number of revolutions a motor will make in a minute for every applied voltage. For instance, a 2200KV rating means the motor will spin 2200 times in a minute when voltage is applied.

Q2: What does a brushless motor controller do?

A2: A brushless motor controller regulates power to the motor, allowing smooth throttle control. It manages the voltage output based on the user's input and ensures the motor works within its set parameters.

Q3: How do brushless motors compare to brushed motors?

A3: Brushless motors outperform brushed motors in efficiency, lifespan, and maintenance. While they come at a higher cost, the long-term benefits make them a worthy investment. Motor types suited for low-cost applications are brushed motors.

Q4: What applications use brushless motors?

A4: Brushless motors are versatile and find use across various applications, including drones, RC cars, and high-performance bikes.