(8916 products available)

Steel laser cutters operate in different ways. They include:

CO2 lasers

Carbon dioxide lasers produce a high degree of heat to cut the material. This cutting machine is ideal for such reflective materials as steel. While they cut slower than other laser types, they are highly effective for heavy-duty cutting. CO2 laser machines are suitable for cutting up to 6 millimeters of steel.

Fiber lasers

Fiber lasers work by delivering laser energy through fiber optic cables. They are usually more efficient than CO2 because they generate a more focused beam. This makes the cutter ideal for detailed or thinner cuts. Fiber lasers are effective for cutting thin sheets of steel, including 1mm thickness.

Disk and rod lasers

Like fiber lasers, disk, and rod lasers offer high precision. They are useful for intricate designs on metal surfaces. Disk and rod lasers, however, are more compact and flexible, suitable for detailed workspaces. They can also handle 1mm steel due to their precision cutting capabilities.

Nd-YAG lasers

These solid-state lasers are known for their ability to mark, engrave, and cut metals. They are especially effective when cutting thin materials such as 1mm steel. In addition, Nd-YAG lasers generate pulses, making them useful for applications requiring heat-sensitive operations.

Precision Manufacturing

Steel laser cutters offer the precision required in developing intricate parts in automotive and aerospace industries. Their application in these industries derives from the cutters' ability to make clean, burr-free edges. This is critical for developing components such as brackets, frames, and engine parts, where accuracy determines performance.

Medical Devices

There is no doubt that steel is widely used in the medical device industry and for good reasons. Laser cutters play a significant role in developing surgical instruments and implants. Steel's strength and biocompatibility enable these devices' durability and reliability. Steel laser cutters support the intricate designs needed for minimally invasive tools, further enhancing their significance in healthcare.

Aerospace Components

Steel laser cutters are increasingly preferred in the aerospace industry due to their precision and ability to handle complex designs. This industry requires materials that can withstand extreme conditions. It also requires precision parts such as fuselages, wings, and engine components. The aerospace industry employs 1mm laser cutters to develop lighter yet strong components critical for safety and performance.

Electronics

Most laser cut steel sheets are used in the electronics industry for casings, heat sinks, and structural components. The automotive and aerospace industries use steel for its electrical conductivity and strength. Laser cutting provides the precision required for complex electronic components. In addition, it ensures they fit and function effectively.

Architectural Applications

1mm laser cut steel sheets are commonly used in modern architectural designs for facades, partitions, and decorative elements. Steel's strength, coupled with the precision of laser cutting, enables detailed work. This supports the growing demand for intricate patterns in both interior and exterior applications. Moreover, the high efficiency of laser cutting results in less material waste. This is critical in construction, where costs can quickly accumulate.

Material thickness

A steel sheet metal laser cutter offers the versatility to handle a variety of thicknesses. They include 1mm to 6mm. For instance, fiber lasers are optimal for thinner materials up to 1mm. CO2 and Nd-YAG lasers can efficiently cut through thicker steel up to 6mm.

Laser power

Generally, the power of a laser cutter is measured in watts. This determines what thickness and material it can handle. For instance, a 1500-watt cutter can handle 1mm steel with maximum efficiency. A more powerful cutter can tackle thicker materials. This makes it a versatile choice for different cutting projects.

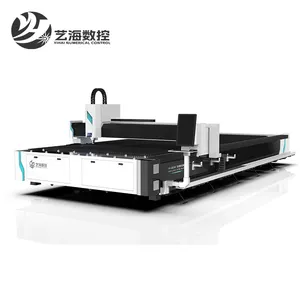

Working area

Laser cutters differ widely in their working areas. This defines the size of the material they can process. A typical working area for a laser cutter is 1.5m by 3m. While this is standard, larger models. For instance, a 1.5m by 3m working area for laser cutting steel sheets can accommodate industrial projects.

High Precision cutting

A laser cutting machine is known for its accuracy when cutting various materials. This is especially true for 1mm steel, as it guarantees smooth, exact edges and complex designs. Its precision supports a wide range of industrial applications, from machinery components to intricate artwork.

Minimal Heat Affected Zone (HAZ)

Unlike other cutting methods, such as plasma cutting, laser cutting produces a small heat-affected zone (HAZ). This means that only a small part of the material around the cutting area is heated. HAZ minimizes distortion and maintains the material's integrity. It, therefore, makes laser cutting ideal for projects requiring tight tolerances.

Versatility

Laser cutting machines are fit for thin and medium materials. They also fit a variety of materials apart from 1mm steel. They include aluminum, copper, wood, and acrylic. This versatility finds laser cutting machines widely useful across numerous industrial sectors.

In addition

Laser machines are also fit for precise engraving, marking, and cutting. Their application is nearly limitless, ranging from industrial fabrication to artistic applications.

Laser type

Each type of laser has its pros and cons when it comes to cutting steel. For instance, fiber lasers are better at handling thin materials. CO2 lasers are ideal for thick materials. Understanding the differences between the laser types will help users select the best for their projects.

Power output

Generally, a laser cutter's power output is critical for effectiveness. A high-power output makes it possible to cut through thicker materials. While lower outputs handle thinner steel conveniently. Buyers should choose power outputs that are suitable for their intended applications.

Industrial needs

Buyers should assess the requirements of their businesses before making a laser cutting machine investment. A busy industry would require a high-speed, high-power laser cutter. On the other hand, a small workshop would get a new lease of life from a low-power, high-precision machine.

Budget

While budget considerations help narrow down options, they shouldn't dictate the choice wholly. Users must weigh the price against potential value and future needs. Fortunately, there are affordable laser cutters; they're also convenient for small workshops. There are also high-end laser cutters, which are ideal for commercial large-scale industries.

Maintenance and support

Like most machines, laser cutters are bound to require maintenance. This can be such a hassle, especially when spare parts are hard to find. Buyers should find out about the costs and requirements of maintenance before investing in a laser cutter. Support, on the other hand, is a critical consideration for buyers who are new to laser cutting. In cases where no support is readily available, users will have to rely on themselves to fix whatever issues arise. This can be a hassle and time-consuming.

In industrial applications, steel laser cutters are commonly used to cut steel sheets into required parts. They are precise and can handle various thicknesses, making them suitable for mechanical, construction, and automotive works. Apart from cutting, they also mark and engrave, adding to their usefulness in detailed industrial branding and identification tasks. In non-industrial applications, steel laser cutters are used in custom art designs such as intricate sculptures, decorative panels, and architectural designs. They enable artists and architects to use steel innovatively for design purposes. The automotive sector uses steel laser cutters in car bodywork, frames, and engine components for their accuracy. The construction industry uses them to cut materials for structural components and frameworks.

Steel laser cutters can cut stainless steel. Stainless steel is known for its durability and resistance to corrosion. It is, therefore, one of the most favorable types of steel in the long run. A laser cutter that can cut stainless steel can also cut other types of steel with 1.5mm thickness. Various industries such as automotive, aerospace, and medical devices prefer stainless steel for its mechanical properties. Users can find stainless steel in both commercial and residential spaces. This is because it is among the most commonly used materials due to its versatility.

Steel laser cutters work wonders for their users. First, they offer high-precision cuts with minimal heat-affected zones, ensuring clean edges that require little to no finishing. Second, they increase cutting speed and productivity while decreasing labor costs. Operations can be performed quickly without needing much manual labor. Steel laser cutters are highly versatile. They adapt to various materials and thicknesses to meet different needs. Moreover, these cutters produce less waste due to their precision. This not only saves costs but also makes the cutting operations environmentally friendly.

Generally, the price of a laser cutter for metal will depend on various factors. They include the type of laser, the size of the machine, and the thickness of the metal it can handle. Additionally, brand and model, and the features of a specific laser cutter also directly influence its price. For instance, a CO2 laser cutter for metal that can handle up to 1.5mm thickness can cost from $5,000 to $30,000. In contrast, a fiber laser cutter for metal which can handle thicknesses of more than 1.5mm to 6mm can cost upwards of $80,000.00. That said, budget-conscious users can find decent metal laser cutters for as low as $2,500. Beyond cheaper options, high-quality laser cutters like CO2 and fiber laser cutters can cost as much as $300,000. It is important to note that lower-priced cutters would be less powerful and of poorer quality than their high-end counterparts. Users should weigh their operational needs against the budget to determine which price bracket they are in.