Understanding 16 RPM: A Key Measurement in Precision Equipment

The term "16 RPM," or revolutions per minute, plays a critical role in various industrial and commercial applications. This measurement is essential for optimizing operational efficiency and ensuring the precise functioning of machinery. Whether dealing with motors, processors, or specialized equipment, understanding 16 RPM helps in making informed decisions regarding selection and usage.

Types of Equipment Operating at 16 RPM

Various types of equipment and devices are designed to operate at a speed of 16 RPM. Here's a breakdown of some common machinery and sectors where this speed is crucial:

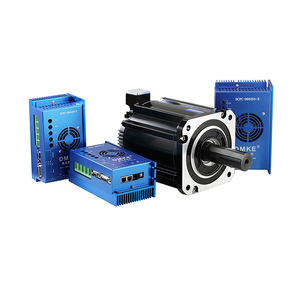

- Industrial Motors: Often used in conveyor systems, these motors are calibrated to operate at 16 RPM for optimal material movement.

- Mixers and Agitators: In food processing, maintaining a specific RPM like 16 ensures a uniform blend of ingredients.

- Rotational Equipment: Devices such as lathes and drills commonly utilize a 16 RPM speed for effective material shaping and cutting.

- Fans and Blowers: Certain ventilation systems are designed to function at this RPM for efficient air circulation while minimizing noise levels.

Applications of 16 RPM in Various Industries

The applications of 16 RPM span multiple sectors, showcasing its versatility and importance:

- Manufacturing: In assembly lines, 16 RPM is ideal for tasks requiring consistent speed without sacrificing quality control.

- Food and Beverage: Equipments like homogenous mixers leverage 16 RPM to maintain texture and consistency in products.

- Automotive: Testing equipment in automotive labs may use 16 RPM to simulate real-world conditions for parts durability assessments.

- Aerospace: Precision testing rigs may rely on 16 RPM for stability and safety testing of components.

Features and Advantages of Equipment Operating at 16 RPM

Choosing equipment that operates at 16 RPM comes with numerous features and advantages that enhance performance and output:

- Precision Control: Operating at a fixed speed like 16 RPM allows for fine-tuning processes, resulting in higher quality outputs.

- Energy Efficiency: Equipment designed for 16 RPM is often optimized to consume less energy, leading to cost savings over time.

- Reduced Wear and Tear: Slower rotational speeds can lead to less mechanical stress on components, prolonging the life of the machinery.

- Versatile Applications: The adaptability of 16 RPM allows its use in various processes without extensive modifications to existing setups.