(1374 products available)

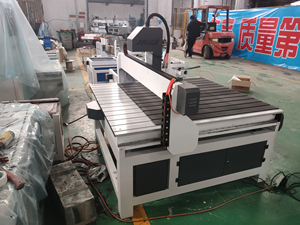

A CNC router is a small-scale CNC machine for cutting, carving, and engraving materials. It is typically moved by a computer program, which gives the material an accurate, delicate, and beautiful design. CNC routers come in five main types: 3D CNC routers, Desktop CNC routers, 1313 CNC wood routers, ATC CNC routers, and OPT CNC routers. The 1313 CNC router is particularly popular because it is an ideal size for working with small to medium-sized materials. It is big enough to accommodate full-size sheets but compact enough to fit into a workshop.

1313 CNC routers are versatile machines that can be used on various materials, including wood, metal, plastic, and composite materials. They are suitable for architectural modeling, sign-making, display design, home decoration, and many other applications.

Like the 1318 CNC router, the working area of a 1313 router refers to the maximum size of the material it can process. While the working area for a 1318 CNC router is 1318x 1318mm, the 1313 CNC router has a working area of 1300mm x 900mm. Although 1313 CNC routers are smaller than some other models, they are still suitable for most projects.

The structure of the machine is generally a heavy-duty square tube, empowering the overall CNC router machine with a stable and robust foundation for high-speed and high-precision carving. 1313 CNC routers have a spindle motor system that provides power for different router bits and may be static or mobile. Mobile spindles are more favorable since they can perform tasks like drilling that might be impossible with static spindles only. A mobile spindle motor moves along the z-axis vertically, while a static motor, also known as a router motor, is permanently fixed to the router. The spindle motor's job is to carve and cut the material. A multi-head CNC router indicates that there is more than one spindle mounted on the machine, allowing the operator to work on different projects simultaneously. Static spindles are generally more straightforward than mobile spindles, as their positions don't move up and down.

Additionally, the CNC has an internal control box armed with a professional DSP controller. The control box houses sensitive electrical components, such as drivers and controllers. Choosing a CNC router with a reliable internal control box is essential, as it determines how well the CNC router performs.

The lifespan of a 1313 cnc router machine depends on the maintenance schedule. Manufacturers and users should always keep the machine parts lubricated and well-oiled. They should also clean the machine after use to prevent the dust build-up that weakens its features. They should also watch for signs of damage and promptly repair or replace worn-out parts. Additionally, they should seek professional assistance when the machine develops complex issues that are hard to diagnose and fix. Below are some 1313 CNC router maintenance tips:

Like any other machine, a 1313 CNC router requires general maintenance. To begin with, users should clean the machines' workstations. They can use brushes or vacuum cleaners to remove any dust or debris built up during operations. Users should also clean any lubricant spills on their surfaces. They should also use blowers or vacuums to clean dust from the machine's rails and tracks.

Secondly, they should regularly inspect the machine to spot signs of damage. For instance, they should check the cutting bits for signs of wear or damage. If they notice any issues, they should promptly replace them to prevent potential damage to the materials being worked on.

Users should also check the air filters in the dust collection systems and the coolant pumps. Clean or replace the filters if necessary to ensure proper function.

Thirdly, maintain the lubricating system. Regularly check the oil reservoir and top up the required grease or oil. Lubricate the moving parts like the rails, bearings, and tracks as recommended by the manufacturer.

Finally, maintain the tool holders and collets. Clean the tool holders and collets to remove debris and buildup. Further, check the tool holders for signs of damage or wear and replace them if necessary.

It's also important to conduct electrical maintenance on the 1313 CNC router. Start by visually inspecting the electrical connections and components. Look for signs of wear, damage, or loose connections. Repair any issues before they develop into bigger problems.

Secondly, users should clean the machine's electronic components. They can use a can of compressed air to blow out the dust from circuit boards and control boxes. Avoid using any liquid cleaning products as they can damage sensitive electronic parts.

Thirdly, users should regularly check the fonts and software in the machine. Update them as per the latest available versions. Also, regularly run antivirus software to eliminate any harmful codes that can interfere with the machine's operation.

Fourth, inspect the power supply unit. Ensure it's working optimally. Check for signs of overheating or damage to the power supply unit and address issues immediately.

The 1313 CNC router serves a variety of industries by making their operations and applications easy. In the advertising industry, the 1313 CNC router is used to make signs and engravings. It cuts through materials like acrylic and wood with precision, creating customized signage for businesses. This includes storefront signs, directional signs, billboards, and decorative signs.

In the woodworking industry, the 1313 CNC router is a valuable tool for making furniture and other complicated woodworking projects. It cuts and engres designs on wood components like tabletops, doors, cabinets, and decorative moldings. The CNC router is also used to control the complicated joinery needed for high-quality furniture assembly.

For those in the crafting and DIY, the CAD/CAM software gives hobbyists and small business owners' options to personalize and create their goods. The 1313 CNC router makes it easy to engrave patterns on wooden plaques, photo frames, cutting boards, and jewelry boxes. It is also used to create intricate designs for home decor items and personalized gifts.

Metal sign manufacturers can take advantage of a CNC router's flexibility to create a variety of intricate designs on metals in a range of gauge options. The best approach to affordably produce a variety of one-off, low-gauge metal parts is to use 1313 CNC routers with high-speed spindle motors. The method prevents the notches, tears, and burn marks that make up the common side effects of conventional machining techniques.

With the help of a software package, users of the CNC router can readily set up a machining process for engraving and cutting lacquered plates, HPLs, metals, woods, and recently introduced organic materials. Simple to create patterns include letters, decorative motifs, forms, and figures.

The following tips will help business owners and other customers when choosing a reliable 1313 CNC router for various projects:

Production Needs

The first step is to identify the required production capacity. Consider the amount of routered material the business requires daily. Factor in the maximum speed at which the machine can operate. Then, choose a model that meets the impressive production volume.

Type of Material

Consider the kind of business material that needs routing. Some CNC machines may not work well on specific materials. However, most 1313 CNC routers can cut wood, acrylic, aluminum, and PVC. Ensure that the chosen machine can handle the work material.

Workpiece Dimensions

Measure the dimensions of the workpieces that need routing. Then, choose a CNC router with a working area that matches the required dimensions. It should be large enough to accommodate the business materials easily.

Required Accuracy and Precision

Determine the necessary accuracy and precision for routing work. Then, look at various 1313 CNC router models and their specifications. Choose a machine with a precision level that matches the required project accuracy.

Control System

Investigate the control systems available on different CNC routers. While some may find a simple numerical control system adequate, others may require an advanced control system. Choose a router with a user-friendly control system that suits the business's needs.

Environmental Considerations

Think about the work environment where the router will reside. Choose a machine with adequate dust extraction and a low noise level to ensure a safe routing environment.

Budget Constraints

Finally, set a budget for the purchase. A typical 1313 CNC router price range exists, so it's easier to find a machine within a particular budget. However, choosing a cost-effective router is essential so that it can improve business productivity.

Q1: What software is compatible with the 1313 CNC Router?

A1: The 1313 CNC Router is compatible with various software options. Common software includes ArtCAM, Aspire, and Type3 for designing. For G-code generation, V-Carve and RouterCAD can be used. Ensure the chosen software can convert designs into G-code that the CNC controller can understand.

Q2: What materials can be used with the CNC 1313?

A2: The Router CNC 1313 can work with different materials. This includes wood varieties like MDF, plywood, and solid wood. Additionally, soft metals, such as aluminum and brass, are compatible. Plastics like PVC, acrylic, and HDPE also work well. Moreover, composite materials and foam can be machined.

Q3: Can the 1313 CNC Router be upgraded in the future?

A3: Yes, one of the key benefits of the 1313 CNC Router is that it can be upgraded in the future. To meet changing needs, businesses can add a 1313 CNC Router's additional tools and accessories. These includes a laser engraving module, a fifth-axis rotary attachment, or a plasma cutter.

Q4: How accurate is the 1313 CNC Router?

A4: The 1313 CNC Router offers a remarkable precision and repeatability in machining operations. Typically, its positioning accuracy is within ±0.02mm. However, this may vary based on factors like the machine's condition, the material being used, and the operator's skill level.