(479 products available)

Ready to Ship

Ready to Ship

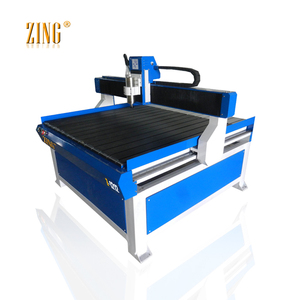

As the cornerstone of the application of CNC technology, the 1200x1200 CNC router plays an important role in the manufacturing of various industries. Based on different classifications, the 1200x1200 CNC routers can be divided into the following types:

The 1200x1200 CNC router is mainly divided into two categories based on the control system: the CNC system and the CNC and PLC integrated system. The CNC system is a centralized numerical control system that uses the principle of computer digital control, which is mainly controlled by the CNC system. The CNC and PLC integrated system combines the advantages of CNC and PLC control systems, which can achieve multi-axis control, tool selection, spindle speed, feed rate, and other functions.

The 1200x1200 CNC router machine moves the tool along the three and more axes to cut the material. According to the movement mode, it is mainly divided into three categories: three-axis CNC routers, four-axis CNC routers, and five-axis CNC routers. The three-axis CNC router is the most common type, with the X, Y, and Z axes controlling the horizontal, vertical, and spindle movements. The four-axis CNC router adds another rotary axis to the three-axis CNC router. The fifth axis of the CNC router spins around the X-axis, which enables the tool to tilt at different angles.

1200x1200 CNC routers come in a range of spindle power options. Usually, they can be divided into three categories: the air-cooled spindle, the water-cooled spindle, and the ATC spindle. The air-cooled spindle is cooled by air, which is better for engraving. The water-cooled spindle is more suitable for cutting, carving, and milling. The ATC spindle is an automatic tool changer spindle, which is used for various applications.

The following are the specifications and various maintenance requirements of 1200x1200 CNC routers.

1200x1200 CNC router machines can have a variety of specifications:

Spindle Motor Power: This determines the cutting power and speed of the CNC router. It is usually measured in kilowatts (kW) or horsepower (HP). Higher spindle motor power allows the CNC router to cut through harder materials faster. A typical CNC 1200x1200 machine could have a spindle motor power of 3.2kW or more.

Cutting Speed: This is the speed at which the CNC router moves and cuts through the material. The cutting speed is usually measured in meters per minute (m/min). Cutting speed may vary with the material and the design of the workpiece. A typical 1200x1200 CNC router can have a cutting speed of 10m/min to 60m/min or more.

Controller System: This is the control system that operates the CNC router. A popular controller system for CNC routers is the Mach3 or Mach4 software. The controller system determines the precision and reliability of the machine. The CNC 1200x1200 router can have a Mach3 controller, Mach4 controller, or others.

Regular maintenance is key to ensuring that the CNC machine runs smoothly and has a long lifespan. The following are some routine maintenance tips for the 1200x1200 CNC router:

Keep the Machine Clean: Thoroughly cleaned machines work better and produce higher quality work. Residual materials and debris can damage the equipment. Debris and dust can also damage the machine's moving parts. The machine should be cleaned after each use. All parts of the machine should be cleaned. It is also a good idea to frequently clean the machine and perform a quick inspection.

Lubrication: Lubrication of moving parts is critical to the proper operation of the machine. Lubrication helps prevent wear and tear on the machine's moving parts. It also ensures the smooth operation of the machine. The machine's moving parts, such as the rails and bearings, should be well lubricated. It is important to use the manufacturer's recommended lubricant. Lubrication should also be part of the routine maintenance.

Check Electronics and Wiring: Regularly inspect and maintain the electrical components and wiring of the CNC router. This includes things like the motor, driver and limit switches. Also, ensure that the wiring is properly connected and insulated. This prevents electrical malfunctions that can damage the machine. It is also important to schedule professional electrical inspections.

Calibration and Alignment: The machine's alignment and calibration should be checked and adjusted regularly. This ensures that the machine is cutting accurately and precisely. The CNC machine's cutting head and spindle should be well aligned. Also, the machine's cutting path should be properly calibrated. Calibration and alignment are essential for maintaining cutting accuracy and quality.

CNC routers are used across various industries for different functions. Some common applications of CNC routers include the following.

1200x1200 CNC wood routers can be used to cut, shape or engrave different types of wood. These include cabinets, furniture components, decorative wood products, and signages. CNC routers are also used in the cabinetry industry to cut and shape cabinet doors, shelves, and other cabinet components with high precision and repeatability. CNC routers can also be used in the furniture industry to create intricate designs and decorative features on furniture pieces. The router's precision and accuracy make it ideal for cutting, carving, and engraving furniture components.

1200x1200 CNC routers are used for rapid prototyping in various industries, including the automotive, aerospace, and electronics industries. The routers can be used to create prototypes of new products or components quickly and accurately. CNC routers are also used for milling various materials, including metals, plastics, and composites. The routers can be used to cut and shape these materials with high precision and repeatability.

1200x1200 CNC routers can be used to create signs and lettering with intricate designs. The routers can be used to cut, carve, and engrave materials such as wood, plastic, and metal to create customized signage. CNC routers are also used in the automotive industry to fabricate interior and exterior components. Some of these components include dashboard panels, trim pieces, and personalized logos. These components are produced with high precision and consistent quality.

CNC routers are also used in the jewelry industry to create intricate jewelry designs. The routers can be used to cut, carve, and engrave materials such as gold, silver, and precious stones. CNC routers are used to create custom jewelry pieces with high precision and attention to detail.

In the education and training sector, CNC routers are used to teach students about CNC technology and programming. The routers can be used to help students learn about router operation, tooling selection, and CNC programming.

When looking to invest in a 1200x1200 CNC router machine, it is crucial to consider the following:

It is important to choose a 1200x1200 CNC router that can provide precise cutting and routing quality. This requires considering the machine's accuracy, repeatability, and control system. Machines with high-resolution stepper motors or servo motors and advanced digital control systems are capable of delivering fine precision and maintaining consistent results.

Selecting the appropriate spindle power and speed is important for achieving efficient cutting and routing. Consider the material requirements and production needs to choose a spindle with the right power rating and adjustable speed. Generally, the machine with the higher spindle power can handle more rigid materials and perform deeper cuts, while the spindle speed affects the cutting quality and efficiency. Also, consider whether the spindle is air-cooled or water-cooled, as this will affect the cooling and noise levels during operation.

The table design and size of the 1200x1200 CNC router directly affect the workpiece support, fixation, and processing area. Choose a table with a suitable surface area and configuration, such as a T-slot or vacuum table, to meet the workpiece's clamping and positioning needs. Also, make sure that the table's load capacity can handle the weight of the workpiece. Additionally, make sure that the machine's Z-axis stroke can accommodate the thickness of the workpiece being processed.

Consider the software used to control the 1200x1200 CNC router, such as design software and the compatibility of the operating system. Certain software offers more advanced design and toolpath capabilities, while the operating system compatibility ensures smooth communication between the software and the CNC router.

Choose a 1200x1200 CNC router with a sturdy frame and high-quality components to ensure its stability and durability during long-term operation. Proper machine construction also helps reduce vibration and maintain high precision. Select a machine from a reputable manufacturer with a good reputation and reliable after-sales service, which is helpful for maintenance and technical support.

Q1: What are the advantages of using a 1200x1200 CNC router?

A1: A 1200x1200 CNC router has many benefits. It can work with bigger workpieces, which means more items can be cut or engraved at once. This can save time and improve efficiency. It also has a bigger working area, which allows for more creativity and flexibility in projects.

Q2: What kind of materials can be processed with a 1200x1200 CNC router?

A2: A 1200x1200 CNC router can process a wide range of materials. Common choices include wood, MDF, plywood, plastic, acrylic, PVC, and double-color sheets. It can also cut softer metals like aluminum, brass, and copper, as well as non-metal materials like stone, glass, and carbon fiber.

Q3: What is the difference between a 1200x1200 CNC router and a laser cutter?

A3: A 1200x1200 CNC router and a laser cutter are both used for cutting, carving, and engraving. However, they work differently. A CNC router uses a spinning tool to cut and shape materials, while a laser cutter uses a high-powered laser beam. CNC routers are better for thicker materials and projects that require more precision, while laser cutters are better for projects that need very high precision, like cutting intricate designs into materials.