Introduction to 10000 RPM Products

In the world of power tools and machinery, the term 10000 RPM (revolutions per minute) signifies the speed and efficiency of various devices. Equipment operating at this rate is designed for high-performance tasks, catering to a range of industries from woodworking to metal fabrication. The capability to achieve 10000 RPM allows these tools to perform intricate and demanding tasks with precision and speed.

Types of 10000 RPM Devices

- Rotary Tools: Often used for grinding, polishing, and engraving, these tools operate at high speeds, making them ideal for detailed work.

- Bench Grinders: Essential in workshops, bench grinders at 10000 RPM allow for effective sharpening and shaping of metal objects.

- High-Speed Drills: These drills cut through various materials swiftly, making them ideal for heavy-duty applications.

- Circular Saws: Saws designed for high-speed cutting in woodworking and metalworking, providing smooth and clean cuts.

Function and Features of 10000 RPM Tools

The core function of tools with a 10000 RPM rating is to deliver superior speed and efficiency. Here are some key features:

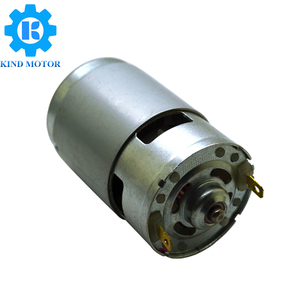

- Powerful Motors: Equipped with robust motors that ensure consistent performance under heavy loads.

- Adjustable Speed Settings: Many tools offer customizable speed control, allowing users to adjust the RPM according to the job at hand.

- Durable Construction: Made from high-quality materials that withstand the rigors of high-speed operation.

- Safety Features: Enhanced safety mechanisms, such as automatic shut-off and protective guards, help minimize risks during use.

Applications of 10000 RPM Equipment

Tools that achieve 10000 RPM are versatile and suitable for various applications, enhancing productivity across multiple sectors:

- Metalwork: Ideal for cutting, grinding, and drilling metals efficiently, catering to machinists and metal fabricators.

- Woodworking: Perfect for intricate carvings, shaping, and sanding hardwoods, beloved by woodworkers and craftsmen.

- Aerospace Industry: Utilized for precise machining of components where performance and accuracy are critical.

- Automotive Repair: Often used in bodywork and engine repairs for quick and effective results.

Advantages of Using 10000 RPM Machines

There are numerous advantages to utilizing 10000 RPM tools in your projects:

- Time Efficiency: High speeds significantly reduce the time it takes to complete tasks, enhancing overall productivity.

- Precision: The capability to operate at high speeds allows for more accurate and intricate work.

- Versatility: Suitable for a range of materials, from soft woods to hard metals, making them a valuable addition to any toolkit.

- Cost-Effective: Investing in high-speed tools can lead to reduced labor costs and increase profitability through quicker project completion.