(4123 products available)

There is a variety of 10 wet grinders. They are distinguished by characteristics such as capacity, purpose, type of operation, and design. These types include tilting, tabletop, commercial, dual stone grinders, and planetary grinders.

Tilting wet grinders

In tilting wet grinders, the drum can be tilted, offering ease in pouring out the batter without much hassle. Out of this feature, convenience is one of the main reasons tilting grinders are mostly used in the restaurants and large-sized homes. These types of grinders are also suitable for preparing idli batter and dosa batter in bulk. Therefore, a tilting 10 wet grinder is a suitable choice for people or companies who use large quantities of ground food.

Tabletop wet grinders

Tabletop grinders are compact wet grinders that are ideal for small households. They are small in size and usually have a single, grinding stone. Tabletop grinders are best used for daily preparations of small quantities of rice, pulses, or grains. These grinders are generally portable and can easily fit into kitchen spaces.

Commercial wet grinders

Commercial wet grinders are created for enterprises use. Such places as restaurants, hotels, and catering businesses commonly use these types of grinders. Commercial grinders are large in capacity, meaning they can grind large quantities of food at once. In addition, they are more durable than other types of wet grinders, seeing that they are constructed for frequent usage.

Dual stone wet grinders

As the name suggests, dual stone grinders have two grinding stones. This kind of grinder is helpful in improving the grinding process. It thus saves time. The two stones are better than one in breaking down food items into finer particles. This makes them good for making very smooth batter.

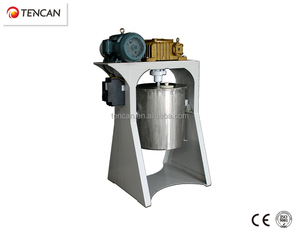

Planetary wet grinders

The design of these grinders is different. In these grinders, the grinding stone rotates in a planetary motion. This helps it mix and grind the ingredients evenly. Planetary wet grinders are useful when different ingredients have to be ground together to make a batter with consistent feel and texture.

Some of the key considerations when buying a 10 wet grinder include material of the grinding stone, the capacity of the grinder, and motor power

Grinding Stone Material

Wet grinders have two types of grinding stones. One is natural stone, and the other is artificial/compound stone. Natural stones, for instance granite, are hard. Thus, it takes time for them to wear out. This means they can be used for longer periods. Artificial stones are made of bonded materials. They wear out faster than natural stones. However, this gives them the ability to grind quickly.

Drum Material

The drums or containers that hold the ingredients while grinding are mostly made from stainless steel. Another material includes stone. Stainless steel is preferred more. This is because it does not rust and is easy to clean. Stone drums are ideal for providing better friction while grinding. However, they are not as common since they are not easy to maintain.

Capacity

Wet grinders are available in a range of capacities. They can be from 1 liter to 10 liters or more. Smaller grinders with 1-2 liters capacity are used for household purposes. While larger capacity grinders are suitable for commercial or industrial use. Bigger the capacity, the less frequent it needs to be filled. This is helpful when preparing large batches of food.

Motor Power

Wet grinders come with motors that vary in power from 150 watts to 2000 watts. Higher power motors are for commercial or heavy-duty usage. While lower power motors are for light, everyday use. More motor power means quicker grinding. It also comfortably handles tougher mixtures.

Speed settings

Some wet grinders have speed settings that can be adjusted. This way, the user can control the grinding speed. It can therefore be set low for mixing batter. Or, it can be set high for grinding spices. This flexibility allows users to get the consistency of their batter or flour the way they want it to be.

Overheating protection

This feature is available on some models. It helps prevent the motor from overheating in case it is used for a long time. This is important because it protects the grinder from damage. It also extends its lifespan.

Users can follow several maintenance practices to keep 10 wet grinders functional and increase their durability. They include washing the drum, cleaning the stone, and using proper care for the motor and belt, among others.

Regular cleaning

The interior of the drum has to be cleaned after every use. Users can wash it with a soft cloth or sponge. They should avoid using harsh detergents. This is because they may damage the surface. The stones must also be cleaned. Most grinders have attachments that help in cleaning the stones. These attachments are used to clean the stones to avoid any build-up of residues between the two stones. If residues build up, they can harden over time. When hard, they may affect the grinding process.

Check and maintain parts

The parts like stones, belts, and even the motor may need some checking frequently. Some parts may end with wear and tear due to continuous operation. For example, worn-out grinding stones will affect the consistency of the batter. On top of that, worn-out stones may also alter the taste of the batter. One has to replace stones as needed to ensure good grinding. The belts used have to be checked often for signs of wear and tear. A worn-out belt will hinder the functionality of the grinder. In some instances, it may even be dangerous. Replace worn-out belts timely to ensure safety and efficient operation. The motor must be checked periodically too, some models have external brushes that need to be replaced from time to time. This helps maintain the motor. In models where the internal brushes have to be replaced, users should not wait too long. Being in possession of a spare set of brushes helps decrease the grinder's downtime.

Lubrication

Some parts need to be lubricated now and then. Lubrication helps reduce friction. This lowers the wear and tear of the moving components. In this case, the motor and the belt. Proper lubrication ensures the wet grinder runs smoothly for some time.

Store properly

The wet grinder should be stored properly when not in use. It should be kept in a dry place. This reduces the chances of rusting on the metal parts. Also, covering the grinder with a dry cloth or its original cover helps protect it from dust and other foreign particles.

Avoid overloading

Avoid putting too many ingredients into the grinder at once. This may cause strain on the motor. Also may cause damage to the internal parts. Always grind in batches if the quantity is too much. This helps prevent the motor from being overworked. It also avoids overheating.

The wet grinder has been used to apply in different processing industries as well as in kitchens.

Food industry

In the food industry, 10 wet grinders are used in the production of batter, flour, and paste. They do these quickly and in large quantities. These types of grinders are commonly used to grind rice and pulses. These grains are soaked beforehand to make a soft batter for idli and dosa.

Catering Services

Users in catering services use 10 wet grinders to prepare huge quantities of batter or dough for events like weddings and parties. They ensure the grinder is able to produce consistent results with the help of these large-capacity grinders. This is in the form of fine or coarse as per the requirement.

Residential/commercial kitchens

Wet grinders are commonly used in both residential and commercial kitchens. This is for preparing batters and pastes. They are especially useful in making smooth, fine batters that are difficult to achieve using dry grinders. Commercial kitchens also employ large 10 wet grinders to efficiently produce large quantities of ground ingredients for their menu.

Spice grinding

Wet grinders can be used to make pastes from spices. These might be soaked or roasted spices. These grinders are used in the production of masala paste, which is an essential component when preparing many Indian dishes.

Historical use

In ancient times, people used stone grinders to ground materials. These materials included grains, nuts, seeds, and pigments. These original grinders eventually evolved into the wet grinders that are used today. This evolution occurred due to the need for smoother textures and finer consistencies in food preparation.

Construction industry

In the construction industry, 10 wet grinders are used to grind materials like marble and concrete. This is especially so for planetary wet grinders. These grinders provide a smooth finish on concrete floors.

Cosmetic Industry

These grinders are used in the cosmetic industry to create smooth, consistent pastes or powders for products like makeup, creams, and lotions. The fine grinding helps in achieving the desired texture in the end products. This enhances their quality and application.

When selecting a 10 wet grinder for clients, businesses should consider the following factors.

Material and durability

Customers have to be directed to models made of sturdy materials such as stainless steel or stone. Tell them these models will last longer. Also, these materials will resist wear and tear. This is especially what is needed for grinding sizable quantities of food.

Grinding stones

Customers also have to be given options with two stones or a single stone as choices. Those that have two stones grind better and more efficiently. Go for tilting or tabletop models that have larger stones for customers who want to grind regularly. In grain manufacturing, larger stones lead to faster production.

Motor power

Clients who will use the grinders for heavy-duty tasks require grinders with powerful motors. Such motors will enable the grinders to handle tough grinding tasks with ease. Small-scale operations do not need much power. So, a motor with a lower wattage will be okay.

Ease of use

Select grinders that have features that enhance their usability. These features could be speed settings, indicator lights, or overheating protection. Consider the models that have an automatic shut-off function to help prevent damage from prolonged use.

Cleaning and maintenance

Advise clients to go for stainless steel models. These models are easy to clean and maintain. Also, some models have detachable parts. This makes cleaning them easy. Additionally, remind clients to select models that come with manufacturers' warranties and customer support. These are essential in case any issues arise later on.

Space requirements

The size of the grinder has to be considered too. Tabletop models are small, so they are suitable for clients with less space. Large-scale operations require large models, though. Think about the space available before purchase. Do not forget to consider the noise level of the model, too. It may seem small, but it is vital. Noisy models will be disruptive. Lastly, keep budgets in mind. Generally, commercial grinders are more expensive. They, however, offer much power and durability.

A1. For grinding materials like aluminum, manufacturers recommend a wet grinder with a high RPM. Go for models that have a powerful motor. A powerful motor means it can handle the task of grinding aluminum with ease.

A2. Some features enhance the efficiency of these grinders. They include premium-quality grinding stones, a powerful motor, speed settings, and a well-designed drum. All these features enable these grinders to grind a variety of materials finely.

A3. Apart from food items, manufacturers have designed these grinders to grind industrial materials. Some of these materials include metals, marble, and concrete. They can even grind pigments for paints.

A4. Customers can reduce this noise level by selecting a model with a powerful motor. More powerful motors tend to create less noise. Additionally, those customers whose workstations have sound-absorbing materials will further help in reducing the noise level.

A5. Yes, many of these models are portable. Customers can easily carry them around. Such models usually weigh less. Also, they have compact designs.

A6. These grinders take about 10 minutes to soak. The manufacturers have designed them to allow users to add a small amount of water to the grains during the grinding process.